Control method for energy multistage utilization of pneumatic motor

An air motor and energy technology, which is applied in the control field of multi-stage utilization of air motor energy, can solve the problems of compressed gas effective energy loss, compressed gas working ability decline, compressed gas energy loss, etc., to improve flow requirements and response time , Improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The present invention will be described in further detail below in conjunction with accompanying drawing.

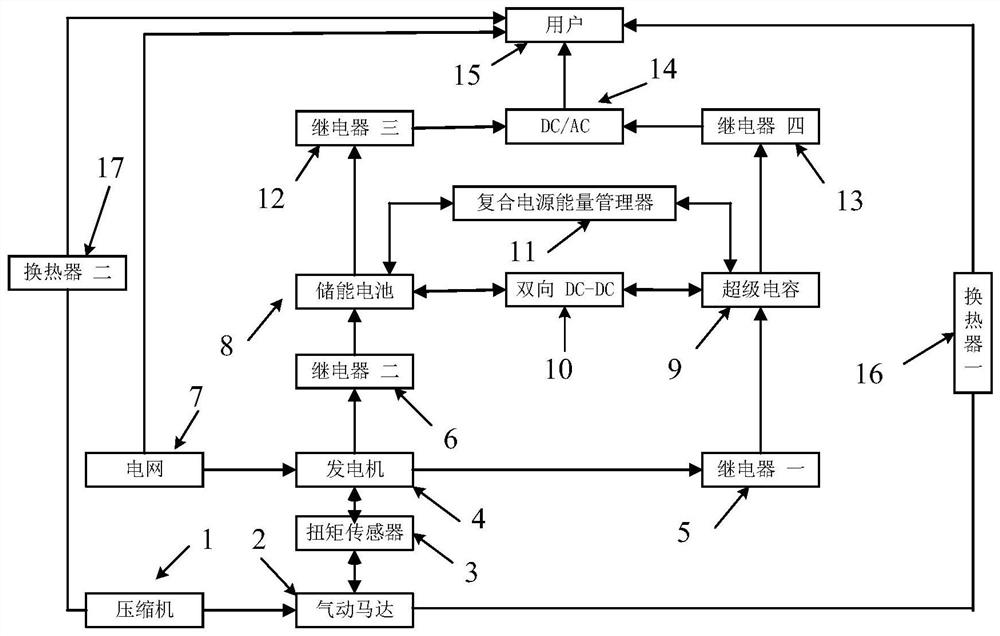

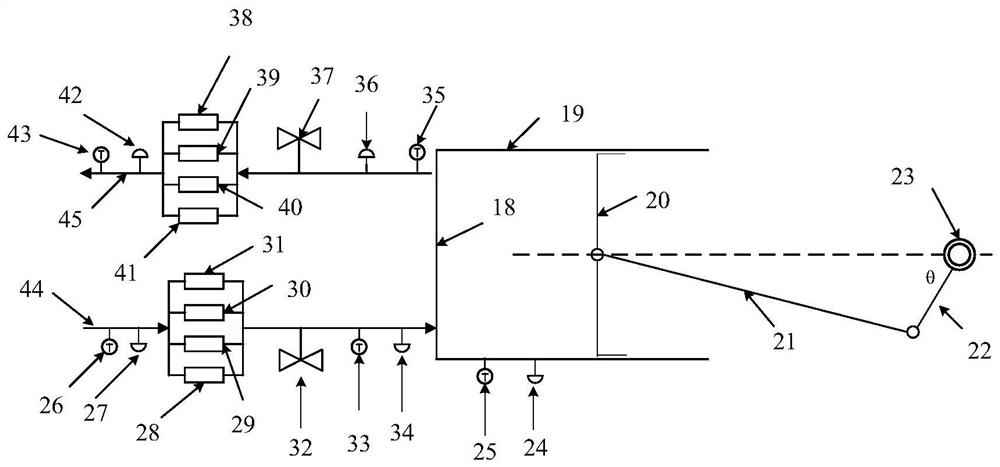

[0030] Such as figure 1 , 2 As shown, a control method for multi-stage energy utilization of an air motor, the technical solution mainly includes an air motor power generation system, an air motor cooling and heating system, and an air motor adjustable expansion ratio and compression ratio system.

[0031] Specifically include: 1. Compressor; 2. Air motor; 3. Torque sensor; 4. Generator; 5. Relay 1; 6. Relay 2; 7. Power grid; 8. Energy storage battery; 9. Super capacitor; 10. Bidirectional DC / DC; 11. Composite power supply energy manager; 12. Relay three; 13. DC / AC; 14. Relay four; 15. User; 16. Evaporator one; 17. Evaporator two; 18. Cylinder head; 19. Cylinder; 20. Piston; 21. Connecting rod; 22. Crankshaft; 23. Encoder; 24. Pressure sensor one; 25. Temperature sensor one; 26. Temperature sensor two; 27. Pressure sensor two; 28. Solenoid valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com