High-nickel positive electrode material and preparation method and application thereof

A positive electrode material, high-nickel technology, applied in nanotechnology, chemical instruments and methods, nickel compounds, etc. for materials and surface science, can solve the problems of difficult mass production, affecting battery power performance, low water content, etc. problem, to achieve good cycle performance and good lithium supplementation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

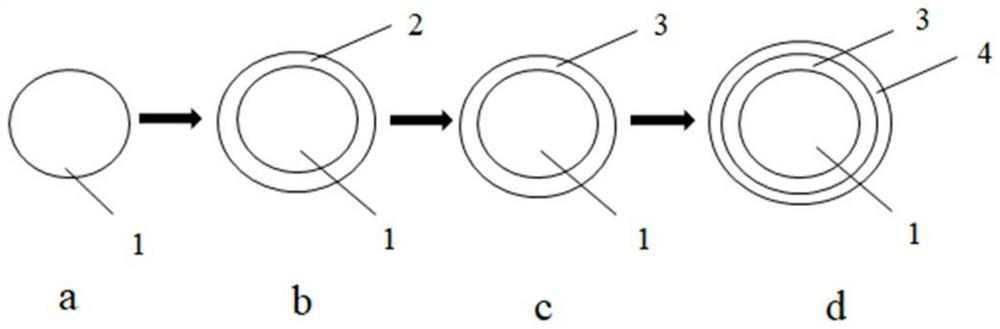

[0077] This embodiment provides a high-nickel positive electrode material, the high-nickel positive electrode material has a core-shell structure, and the core material is LiNi 0.83 co 0.12 mn 0.05 o 2 , the shell material is Li 2 Ni 0.83 co 0.12 mn 0.05 o 2 , the molar ratio of the core material and the shell material is 1:0.06, the radius of the core material is 4.9 μm, the thickness of the shell material is 0.1 μm, and the nano-coating layer is nano-Al 2 o 3 (The mass percentage of the added amount in the high-nickel positive electrode material is 0.5wt%).

[0078] The preparation process of the above-mentioned high-nickel positive electrode material includes the following steps (the structure of the high-nickel positive electrode material changes in the synthesis process as shown in figure 1 shown):

[0079] (1) The high-nickel positive electrode raw material (agglomerated type, structure such as figure 1 Shown in a) and water are added to the reaction kettle, d...

Embodiment 2

[0084] This embodiment provides a high-nickel positive electrode material, the high-nickel positive electrode material has a core-shell structure, and the core material is LiNi 0.83 co 0.12 mn 0.05 o 2 , the shell material is Li 2 Ni 0.83 co 0.12 mn 0.05 o 2 , the molar ratio of the core material and the shell material is 1:0.37, the radius of the core material is 4.5 μm, the thickness of the shell material is 0.5 μm, and the nano-coating layer is nano-Al 2 o 3 (The mass percentage of the added amount in the high-nickel positive electrode material is 0.5wt%).

[0085] The preparation process of the above-mentioned high-nickel positive electrode material comprises the following steps:

[0086] (1) Add the high-nickel positive electrode raw material (agglomerated type) and water shown in formula I with a mass ratio of 5:1 into the reactor, dissolve for 30 minutes, and obtain the high-nickel positive electrode raw material slurry;

[0087] (2) performing solid-liquid se...

Embodiment 3

[0091] This embodiment provides a high-nickel positive electrode material, the high-nickel positive electrode material has a core-shell structure, and the core material is LiNi 0.83 co 0.12 mn 0.05 o 2 , the shell material is Li 2 Ni 0.83 co 0.12 mn 0.05 o 2 , the molar ratio of the core material and the shell material is 1:0.95, the radius of the core material is 4.0 μm, the thickness of the shell material is 1.0 μm, and the nano-coating layer is nano-Al 2 o 3 (The mass percentage of the added amount in the high-nickel positive electrode material is 0.5wt%).

[0092] The preparation process of the above-mentioned high-nickel positive electrode material comprises the following steps:

[0093] (1) Add the high-nickel positive electrode raw material (agglomerated type) and water shown in Formula I with a mass ratio of 5:1 into the reactor, and dissolve for 60 minutes to obtain the high-nickel positive electrode raw material slurry;

[0094] (2) performing solid-liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com