Royal jelly concentration and purification process and royal jelly concentration and purification production line

A royal jelly and production line technology, applied in food science and other directions, can solve the problems of inability to concentrate diluents, long freeze-drying time, etc., and achieve the effects of accelerating dehydration speed, improving filtration efficiency, and improving the effect of turning materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

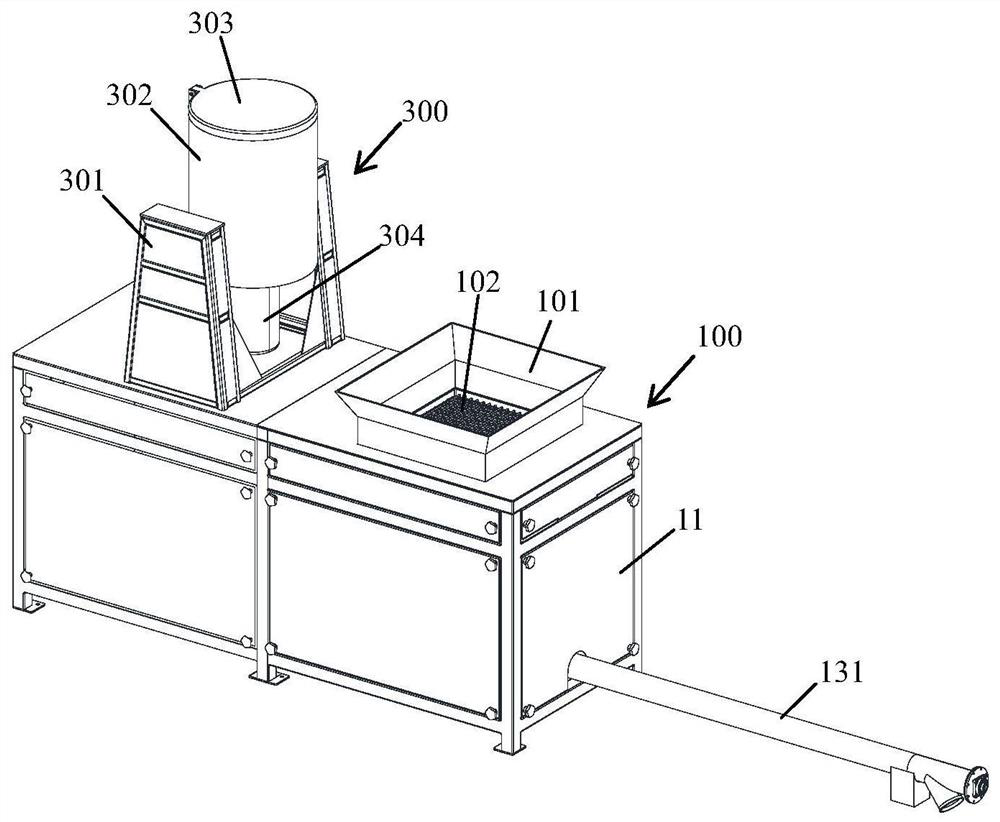

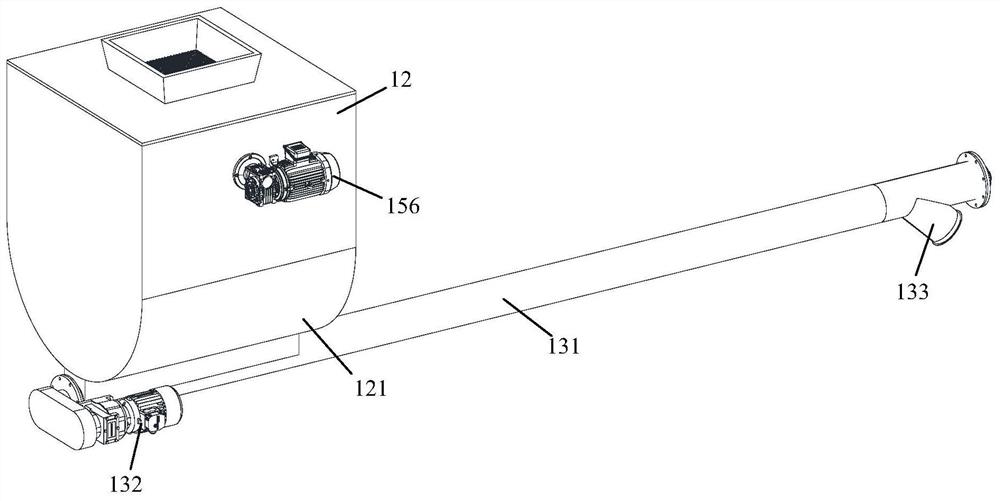

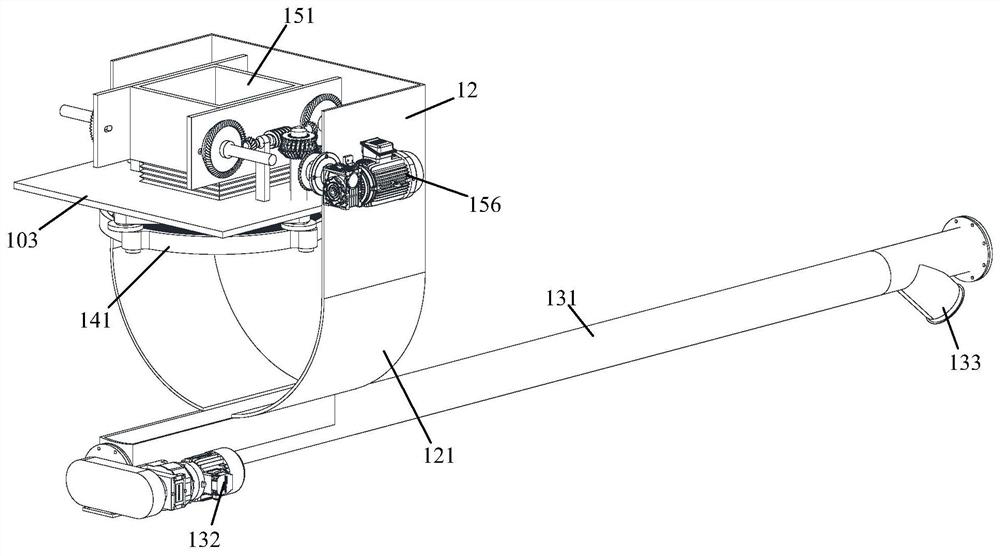

[0059] The invention provides a process for concentrating and purifying royal jelly, such as Figure 29 shown, including the following steps:

[0060] Firstly, the collected royal jelly is mixed with water according to the ratio of 1:1 to 10 in parts by mass to form a royal jelly dilution. In the dilution process, when the proportion of water is too high, it takes too long to concentrate and dehydrate in the subsequent process, and when the proportion of water is too low, the dilution of royal jelly will be too viscous and the filtration efficiency will be reduced. Therefore, in this embodiment , The mass ratio of the collected royal jelly mixed with water is preferably 1:1~2, in the case of this ratio, the royal jelly dilution is formed into a paste, the dehydration time is short, and it will not be too viscous.

[0061] (2) Filter the royal j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com