Antibacterial paper cup and production method thereof

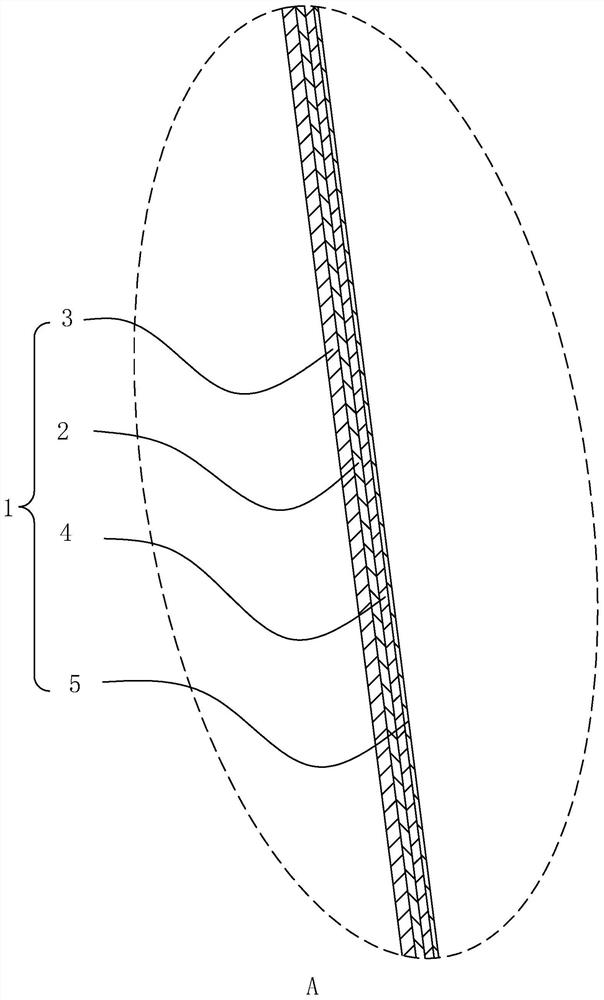

A production method and technology of antibacterial paper, applied in the field of paper cups, can solve problems such as poor antibacterial properties, achieve the effects of improving stiffness, improving corrosion resistance and high temperature resistance, and improving strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0076] The modification method of starch modified sepiolite is:

[0077] Configure 2wt% tapioca starch solution, gelatinize at 80°C for 70min, use 0.1M NaOH solution to adjust the pH of the gelatinized starch solution to 10.5, add acetic acid to the solution, the mass ratio of tapioca starch to acetic acid is 1:0.5, and the starch Heat the mixture with acetic acid at 90°C for 30min; add the above-mentioned heated mixture into 120g / L sepiolite aqueous suspension, stir at 80°C for 15min, adjust the pH of the solution to 2 with 2M HCl solution, and finally wash with water Precipitate to neutrality and dry to obtain starch-modified sepiolite.

preparation example 2

[0079] The modification method of starch modified sepiolite is:

[0080] Configure 5wt% tapioca starch solution, gelatinize at 90°C for 50min, use 0.3M NaOH solution to adjust the pH of the gelatinized starch solution to 11.5, then add acetic acid to the solution, the mass ratio of tapioca starch to acetic acid is 1:2, and the starch Heat the mixture with acetic acid at 80°C for 60min; add the above-mentioned heated mixture into 160g / L sepiolite aqueous suspension, stir at 90°C for 10min, adjust the pH of the solution to 3 with 1M HCl solution, and finally wash with water Precipitate to neutrality and dry to obtain starch-modified sepiolite.

preparation example 3

[0082] The modification method of starch modified sepiolite is:

[0083] Prepare 3wt% cassava starch solution, gelatinize at 85°C for 60min, use 0.2M NaOH solution to adjust the pH of the gelatinized starch solution to 11, then add acetic acid to the solution, the mass ratio of tapioca starch to acetic acid is 1:1, and the starch Heat the mixture with acetic acid at 85°C for 45min; add the above-mentioned heated mixture into 140g / L sepiolite aqueous suspension, stir at 85°C for 13min, use 1.5M HCl solution to adjust the pH of the solution to 2.5, and finally use water The precipitate was washed to neutrality and dried to obtain starch-modified sepiolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com