Vacuum coating anti-fog lens and preparation method thereof

A vacuum coating and lens technology, applied in the field of lenses, can solve the problems of troublesome maintenance, high cost, and short effective duration, and achieve the effects of no environmental pollution, high transmittance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

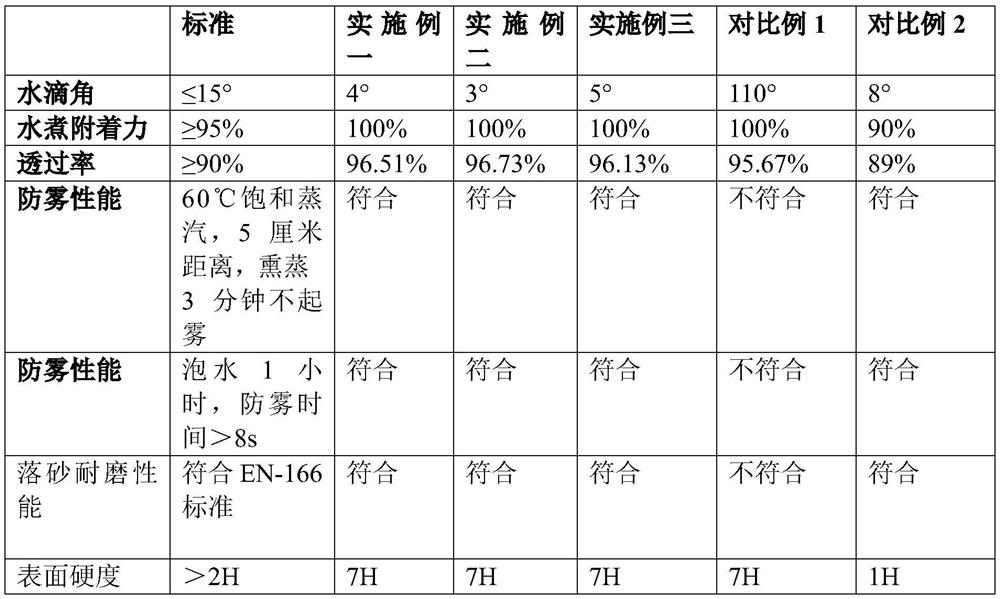

Embodiment 1

[0032]The surface-added polyurethane resin lens is cleaned with ultrasonic waves, and dried at 60 ° C for 30 min, take it out, and returned to normal temperature;

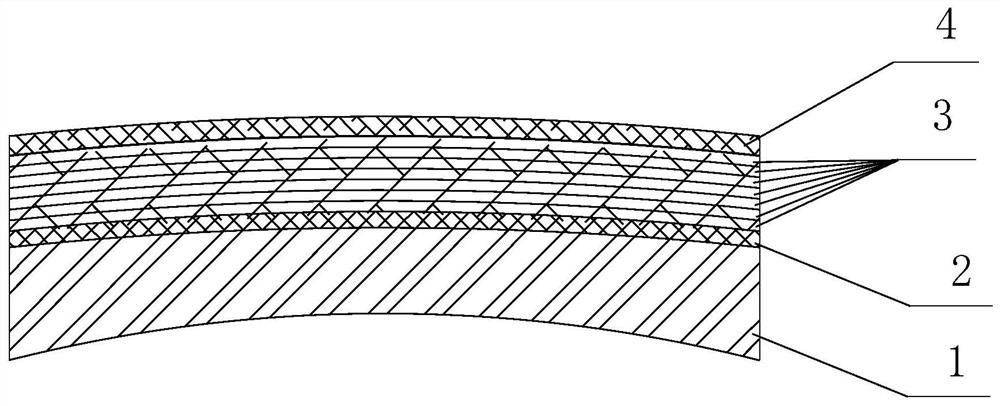

[0033]The removed resin lens will be plated in a vacuum coating machine, and the specific process is, vacuum to 1.0 * 10--5PA, ion bombardment resin lens hard layer surface is activated, sequentially plated SIO2Zro2SiO2Zro2, ITO, Al2O3SiO2, Then ion source bombardment, ion process treatment activation surface, and finally plated anti-fog layers;

[0034]Specific sequential plating 115nmsio2, 25 nmzro220nmsio245nm Zro2, 8nm ITO, 6nm Al2O3, 60nm SIO2, 25 nm of organic silicon polymer anti-fog layer.

[0035]The specific plating process is: 10% electron gun power, the resistance heat radiation power is: 15%, the male stage current: 2A, the male stage voltage: 100V; the flow rate of Arccm, O2The flow rate is 20 sccm;

[0036]SiO2Evaporation rate 0.8 nm / s, Zro2Evaporation rate of 1.0 nm / s, Al2O3Evaporation rate 0.5 nm / s, special io...

Embodiment 2

[0040]The hard resin lens was cleaned with ultrasonic waves and dried at 60 ° C for 30 min, take it out, and returned to normal temperature;

[0041]Place the above lenses into a vacuum coating machine plated anti-fog film, the specific process is, vacuum pumping to 1.0 * 10-3PA, ion beam bombardment lens is activated, sequentially plated SIO2Zro2SiO2Zro2, ITO, Al2O3SiO2, Ion source bombardment, plating special ion process treatment layer and anti-fog layer;

[0042]Specific gating 118nmsio2, 25 nmzro220nmsio246nm Zro2, 10nm ITO, 6nm Al2O3, 55nm SIO2The anti-reflection film group layer, 16 nm of organic silicon polymer fog layer.

[0043]The specific plating process is: 15% electron gun, the thermal radiation power of the electrical resistance is: 12%, male stage current: 3A, male stage voltage: 120V; AR flows 30 sccm, O2The flow rate is 10sccm;

[0044]SiO2Evaporation rate 0.6 nm / s, Zro2Evaporation rate of 1.5 nm / s, Al2O3The evaporation rate of 0.5 nm / s, the special ion process treatment...

Embodiment 3

[0048]The hard resin lens was cleaned with ultrasonic waves and dried at 60 ° C for 30 min, take it out, and returned to normal temperature;

[0049]Take out the above lenses, plated into a vacuum coating machine to prepare a fog membrane, and its specific process is, vacuum to 1.0 * 10-3PA, ion beam bombardment lens is activated, sequentially plated SIO2Zro2SiO2Zro2, ITO, Al2O3SiO2, Then ion source bombardment, plating special ion process treatment layer and anti-fog layer;

[0050]Specific plating 120nmsio230nmzro220nmsio2, 50 nm Zro2, 6nm ITO, 10nm Al2O3, 65nm SIO230nm Ti3O5, 20 nm of organic silicon polymer anti-fog layer.

[0051]The specific coating process is: its plating process is: the electron gun power is 10%, the resistance heat radiation power is: 13%, the male stage current: 3A, the male stage voltage: 90V; the flow rate of the AR is 20 Sccm, O2 is 30 sccm;

[0052]SiO2Evaporation rate of 1.0 nm / s, Zro2Evaporation rate of 1.0 nm / s, Al2O3The evaporation rate of 0.5 nm / s, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com