Preparation method for nanometer composite anti-fogging film

A nano-composite, anti-fog film technology, applied in coatings and other directions, can solve problems such as difficulty in adhesion between coatings and substrates, and achieve good practical application value, good surface smoothness, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

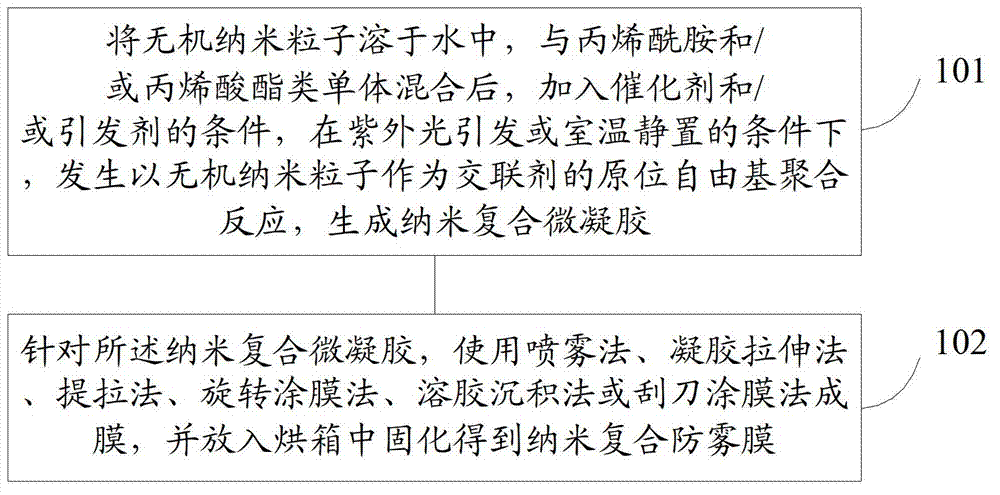

[0032] refer to figure 1 ,show figure 1 It is a flow chart of the steps of the embodiment of the preparation method of a nanocomposite anti-fog film of the present application, which may specifically include the following steps:

[0033] Step 101, dissolving inorganic nanoparticles in water, mixing them with acrylamide and / or acrylate monomers, adding catalysts and / or initiators, under the conditions of ultraviolet light triggering or standing at room temperature, the formation of inorganic In situ radical polymerization of nanoparticles as cross-linking agents to generate nanocomposite microgels.

[0034] In the present application, the inorganic nanoparticles may be any one or a mixture of clay, silicon dioxide, titanium dioxide, aluminum oxide, zinc oxide, magnesium oxide or zirconium oxide.

[0035] Preferably, when the inorganic nanoparticles are silicon dioxide or titanium dioxide, the particle diameter of the inorganic nanoparticles may be 2-40 nm.

[0036] Since thi...

Embodiment 1

[0061] Embodiment 1, join 0.8g clay in the 100ml vial that 50ml ultrapure water is housed, pass nitrogen gas under the condition of magnetic stirring for 15 minutes, add 0.505g N-methylolacrylamide, stir under nitrogen condition for 15 minutes, then put N 2 Move to the liquid surface and continue to pass N 2 After stirring at a slow speed for 15 minutes, 1 ml of 2% sodium thiosulfate and 20 μl of azobisisobutyronitrile were added, sealed and left to stand for 2 hours to obtain a clay nanocomposite microgel.

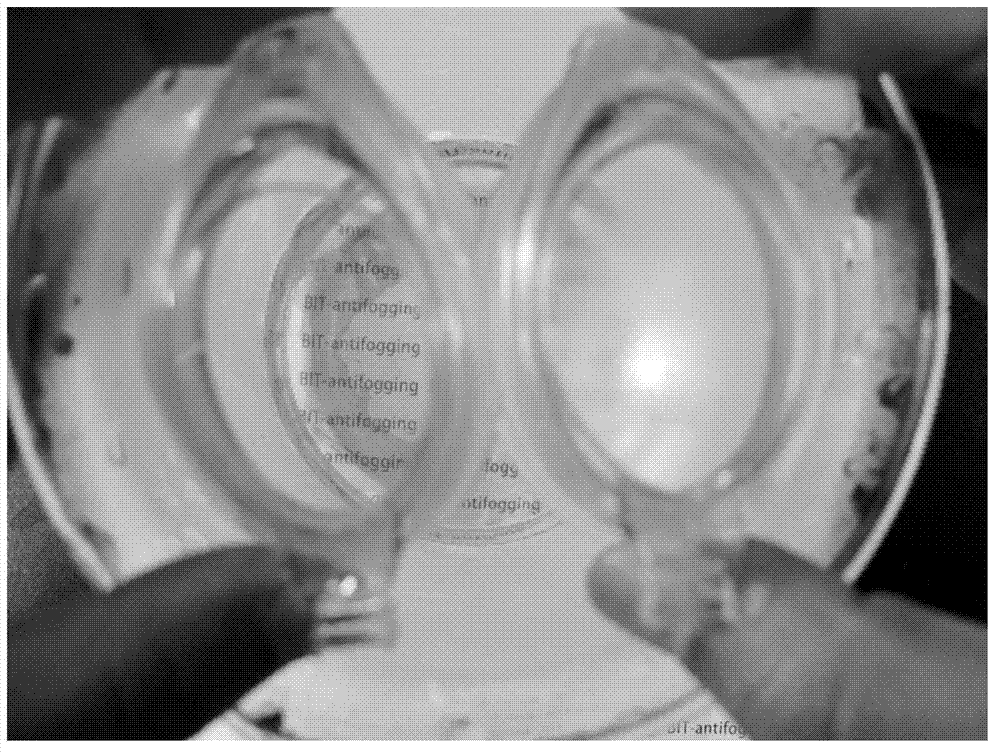

[0062] Put the glass substrate into a 90mm glass Petri dish, add 15ml of the prepared clay nanocomposite microgel, put it horizontally in an oven at 55°C for 24 hours, and use the self-deposition method to prepare an anti-fog film; at the same time, deposit the sol on On the lens of the swimming goggles, put the swimming goggles on the water vapor at 80°C to test the anti-fog effect. figure 2 It is the anti-fog effect diagram of the anti-fog film prepared in Example 1....

Embodiment 2

[0071] Example 2: Add 0.8g of clay into a 100ml vial containing 50ml of ultrapure water, pass nitrogen for 15 minutes under magnetic stirring, add 0.36g of acrylamide, stir for 15 minutes under nitrogen, and then add N 2 Move to the liquid surface and continue to pass N 2 After stirring slowly for 15 minutes, 1ml of potassium persulfate with a concentration of 2% and 20μl of N,N,NˊNˊ-tetramethylethylenediamine were added, sealed and left for 2 hours to obtain a clay nanocomposite microgel.

[0072] Put the glass substrate into a 90mm glass Petri dish, add 15ml of the prepared clay nanocomposite microgel, put it horizontally in an oven at 55°C for 24 hours, and use the auto-deposition method to prepare an anti-fog film.

[0073] The performance parameters of the anti-fog film prepared in Example 2 are as follows:

[0074] Anti-fog: 8 minutes

[0075] Hardness: 2H

[0076] Adhesion: >98%

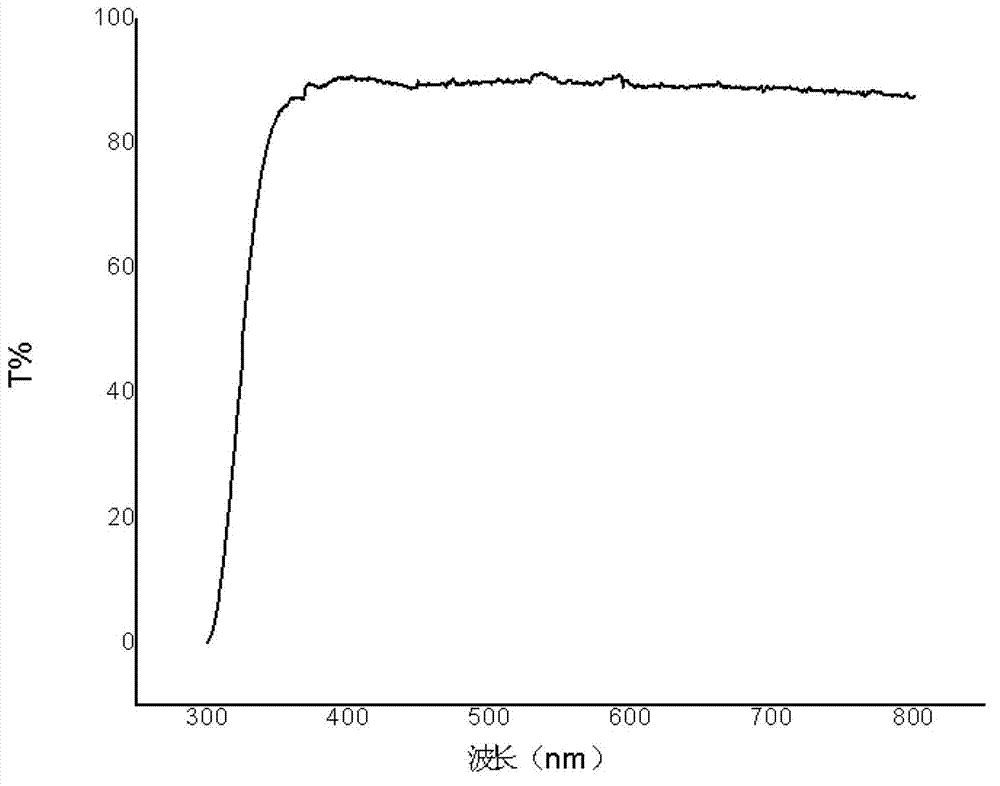

[0077] Light transmittance: qualified

[0078] Contact angle: 41°

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com