Processing method of pig feed

A processing method and technology of pig feed, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve problems such as affecting the growth rate of pigs, nutritional imbalance of pigs, and decreased immunity, so as to improve immune function and resistance to immunity. The effect of stress ability, promoting digestion and absorption, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

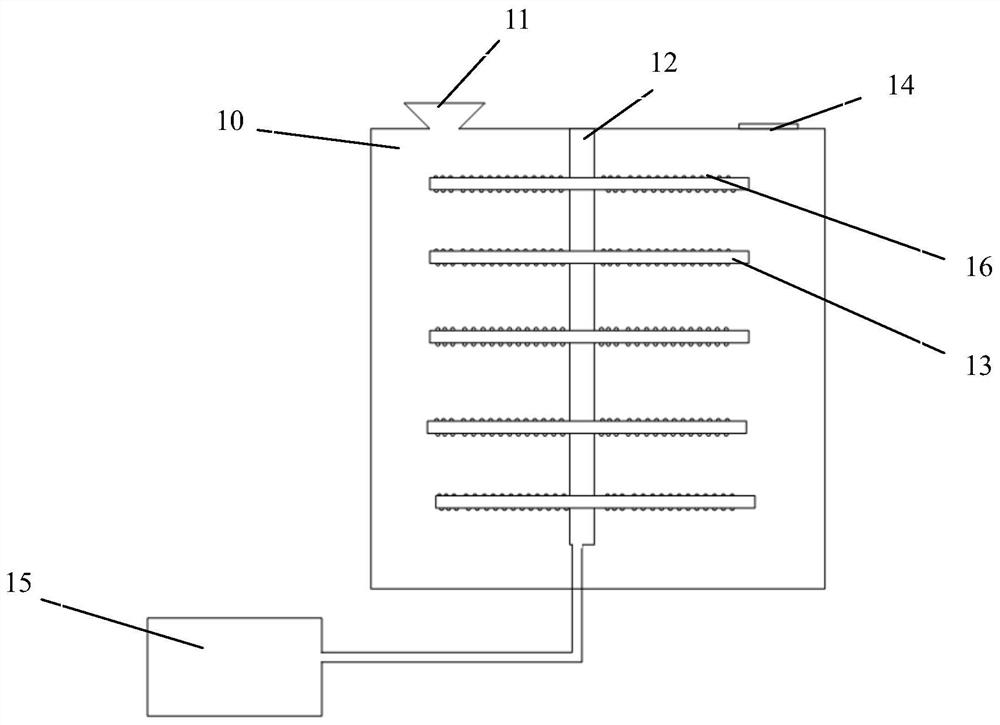

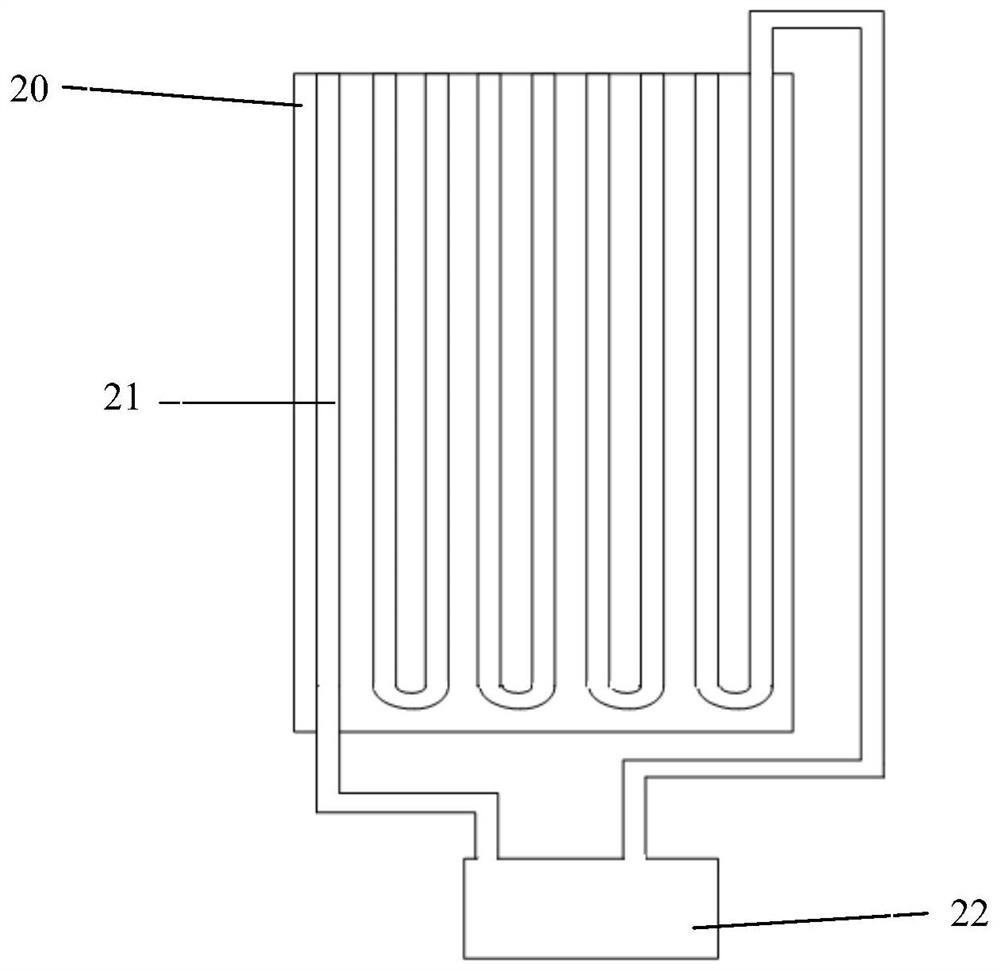

Method used

Image

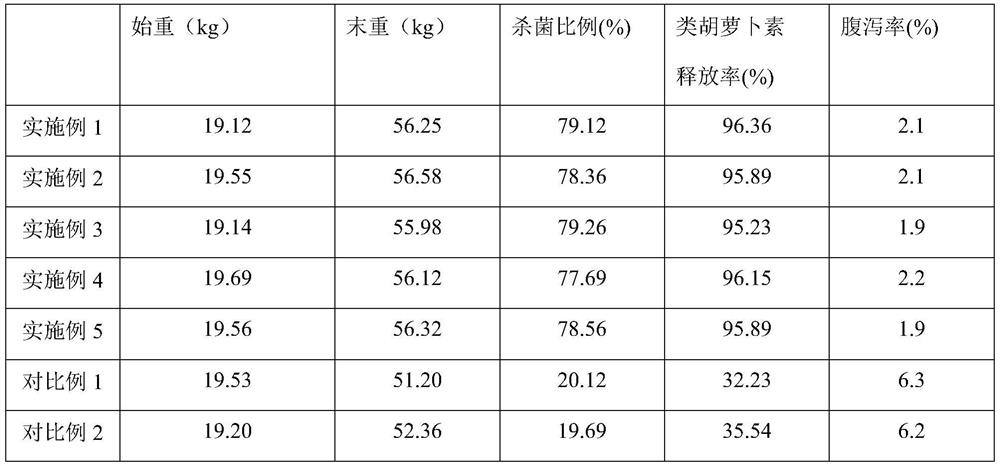

Examples

Embodiment 1

[0049] Present embodiment 1 provides a kind of processing method of pig feed, and step comprises:

[0050] Step 1: Shred

[0051]1.1) According to the mass parts, 50 parts of corn kernels, 5 parts of fish meal, 30 parts of fermented soybean meal, 50 parts of bran and 20 parts of black soybean are roughly ground to a particle size of 5mm;

[0052] 1.2) Then finely grind the mixture after the coarse powder to a particle size of 2mm;

[0053] Step 2: Ripening

[0054] 2.1) Put the pulverized mixture into the aging bin for the first aging, the temperature of the first aging is 120°C, the time is 6min, and the steam conditioning moisture is 25%;

[0055] 2.2) Put the mixture after the first aging into the cooling tower for the first cooling, after cooling to 50°C, put it into the aging bin for the second aging, the temperature of the second aging is 100°C , the time is 5min, and the steam conditioning moisture is 20%;

[0056] 2.3) put the mixture after the second slaking into ...

Embodiment 2

[0073] Present embodiment 2 provides a kind of processing method of pig feed, and step comprises:

[0074] Step 1: Shred

[0075] 1.1) According to the parts by mass, 70 parts of corn kernels, 8 parts of fish meal, 55 parts of fermented soybean meal, 70 parts of bran and 30 parts of black soybean are roughly ground to a particle size of 10mm;

[0076] 1.2) Then finely grind the mixture after the coarse powder to a particle size of 3mm;

[0077] Step 2: Ripening

[0078] 2.1) Put the pulverized mixture into the aging bin for the first aging, the temperature of the first aging is 150°C, the time is 10min, and the steam conditioning moisture is 35%;

[0079] 2.2) Put the mixture after the first aging into the cooling tower for the first cooling, after cooling to 60°C, put it into the aging bin again for the second aging, the temperature of the second aging is 110°C , the time is 8 minutes, and the steam conditioning moisture is 30%;

[0080] 2.3) put the mixture after the sec...

Embodiment 3

[0097] Present embodiment 3 provides a kind of processing method of pig feed, and step comprises:

[0098] Step 1: Shred

[0099] 1.1) According to parts by mass, coarsely grind 55 parts of corn kernels, 6 parts of fish meal, 35 parts of fermented soybean meal, 55 parts of bran and 21 parts of black beans until the particle size is 7mm;

[0100] 1.2) Then finely grind the mixture after the coarse powder to a particle size of 2mm;

[0101] Step 2: Ripening

[0102] 2.1) Put the pulverized mixture into the aging bin for the first aging, the temperature of the first aging is 130°C, the time is 7 minutes, and the steam conditioning moisture is 28%;

[0103] 2.2) Put the mixture after the first aging into the cooling tower for the first cooling, after cooling to 52°C, put it into the aging bin again for the second aging, the temperature of the second aging is 103°C , the time is 6 minutes, and the steam conditioning moisture is 22%;

[0104] 2.3) put the mixture after the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com