Regeneration method of mercury removal adsorbent

An adsorbent and mercury removal technology, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of poor effect, high cost and complicated process of mercury removal adsorbent regeneration technology, and achieve the goal of maintaining mercury removal capacity, avoiding waste of resources, and recovery of surface active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

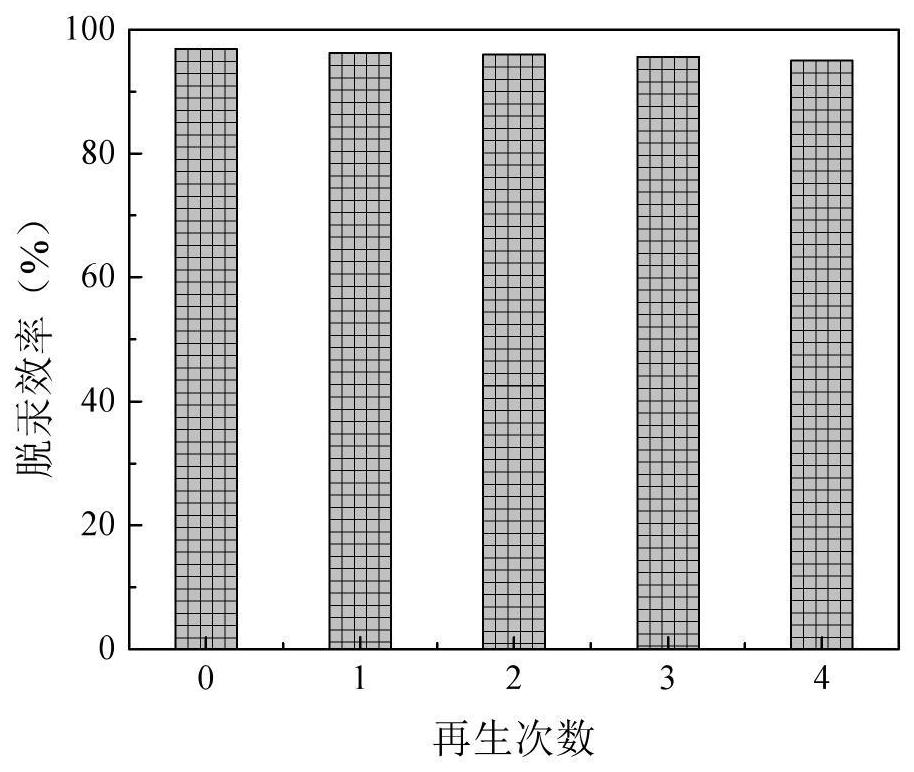

Embodiment 1

[0036] Take out the mercury-removing adsorbent after absorbing elemental mercury in Comparative Example 1, weigh 40 mg of the sample and put it into the crucible, put the crucible into the quartz reaction tube, and let it flow under the nitrogen gas with a volume ratio of 1:1 at a flow rate of 0.02 m / s. Under the atmosphere of mixed gas with oxygen, the tube furnace was raised from room temperature to 300 °C at a rate of 15 °C / min, kept at a constant temperature for 2 hours, then stopped heating, cooled to room temperature and taken out to prepare a thermally regenerated metal oxide mercury removal adsorbent . Applied to mercury removal: the initial mercury removal efficiency is about 94.62%, and it remains at about 46.37% after 240 minutes.

Embodiment 2

[0038] Take out the mercury-removing adsorbent after absorbing elemental mercury in Comparative Example 1, weigh 40 mg of the sample and put it into the crucible, put the crucible into the quartz reaction tube, and let it flow under the nitrogen gas with a volume ratio of 1:1 at a flow rate of 0.02 m / s. Under the atmosphere of mixed gas with oxygen, the tube furnace was raised from room temperature to 400 °C at a rate of 15 °C / min, kept at a constant temperature for 2 hours, then stopped heating, cooled to room temperature and taken out to prepare a thermally regenerated metal oxide mercury removal adsorbent . Applied to mercury removal: the initial mercury removal efficiency is about 97.87%, and it remains at about 62.97% after 240 minutes.

Embodiment 3

[0040] Take out the mercury-removing adsorbent after absorbing elemental mercury in Comparative Example 1, weigh 40 mg of the sample and put it into the crucible, put the crucible into the quartz reaction tube, and let it flow under the nitrogen gas with a volume ratio of 1:1 at a flow rate of 0.02 m / s. Under the atmosphere of mixed gas with oxygen, the tube furnace was raised from room temperature to 500 °C at a rate of 15 °C / min, kept at a constant temperature for 2 hours, then stopped heating, cooled to room temperature and taken out to prepare a thermally regenerated metal oxide mercury removal adsorbent . Applied to mercury removal: the initial mercury removal efficiency is about 95.31%, and it remains at about 47.23% after 240 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com