Processing method of 3D printing silicon carbide reflector

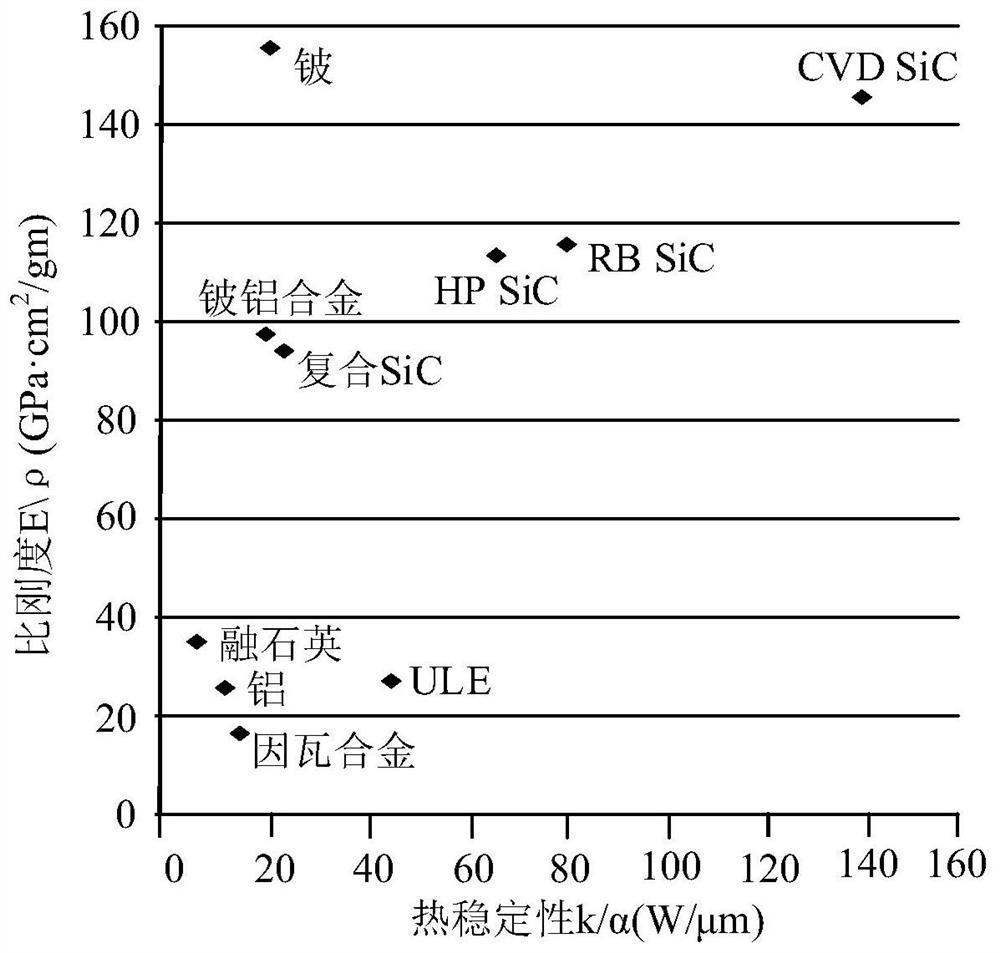

A technology for printing silicon carbide and a processing method, which is applied in the processing field of optical components, and can solve the problems of uneven distribution of phase materials, large differences, and difficult processing and molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

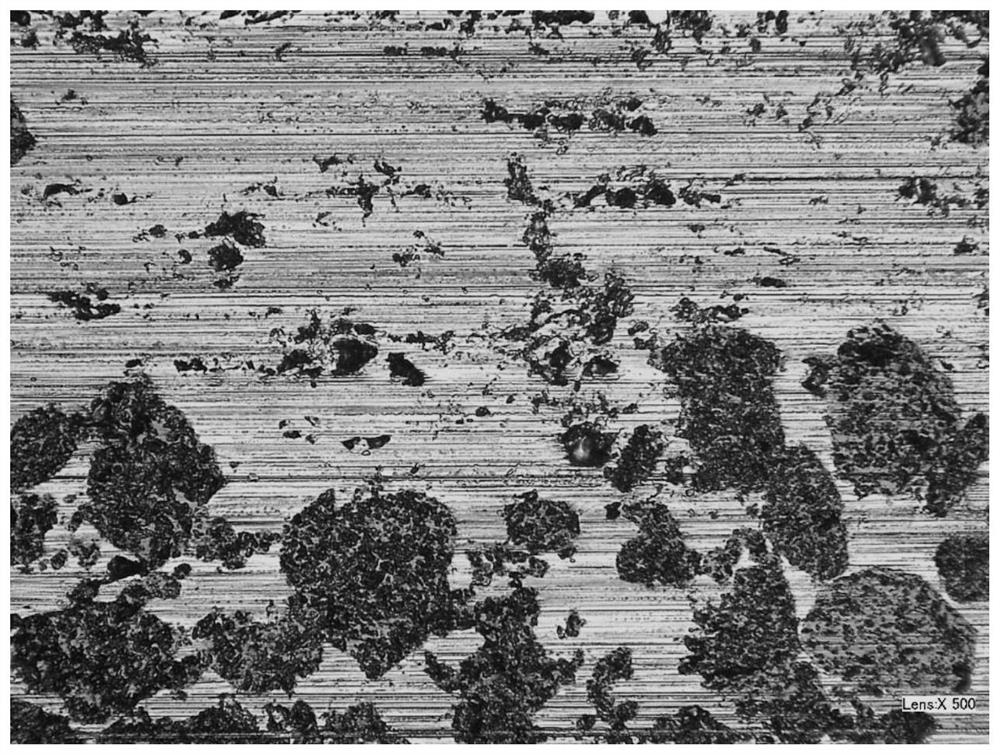

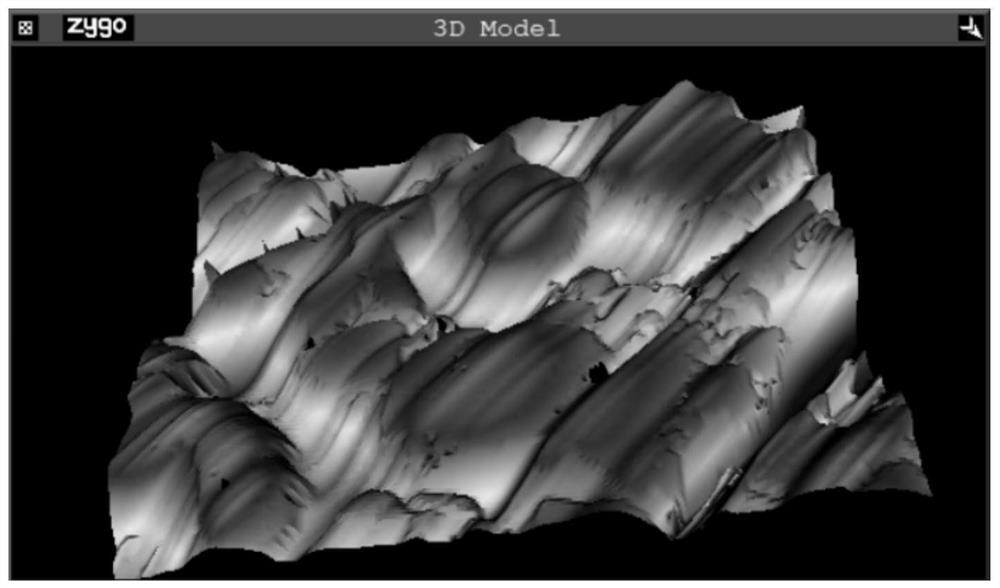

[0045] The workpiece in this embodiment is a 3D printed silicon carbide plane mirror with a diameter of 100 mm. The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, and the combined polishing method used in the present invention will be further described.

[0046] Such as Figure 5 As shown, the steps of the 3D printing silicon carbide mirror combined polishing processing method in this embodiment include:

[0047] 1) Carry out surface grinding on the printed silicon carbide blank workpiece, remove the pits and protrusions on the surface of the workpiece, and obtain a flat workpiece surface;

[0048] 2) Carry out small grinding head grinding and rough polishing on the workpiece to be processed to obtain a reflector surface that meets the initial surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com