Ultraviolet-proof and blue-light-proof laminated glass capable of dimming or emitting light

A technology of laminated glass and ultraviolet light, applied in glass/slag layered products, coatings, optics, etc., can solve the problem of not being able to meet the requirements of UV protection and blue light protection at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

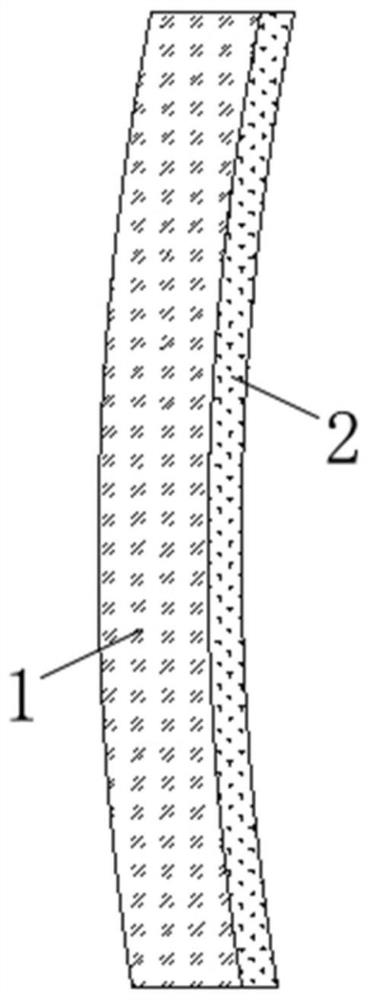

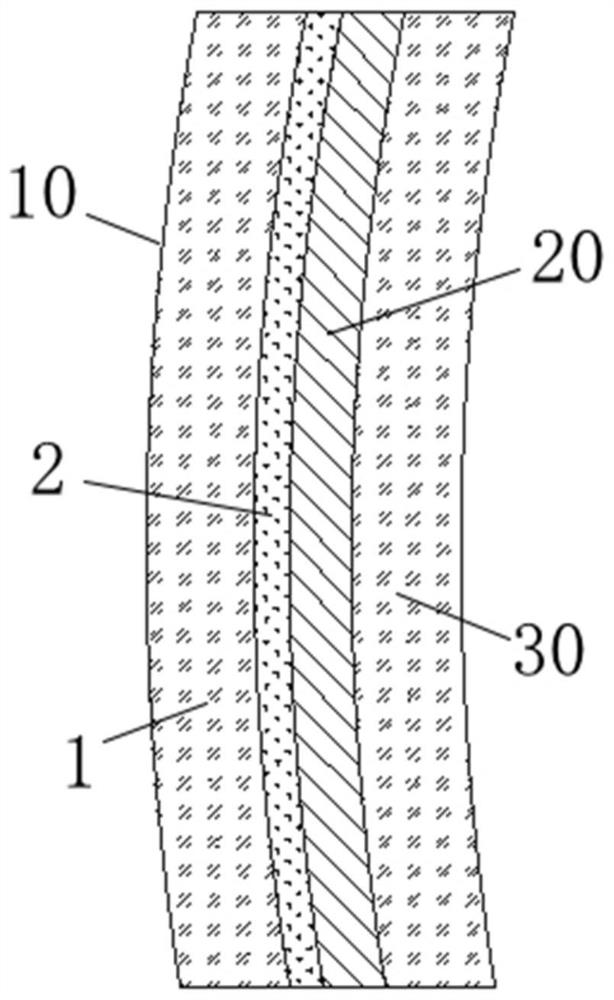

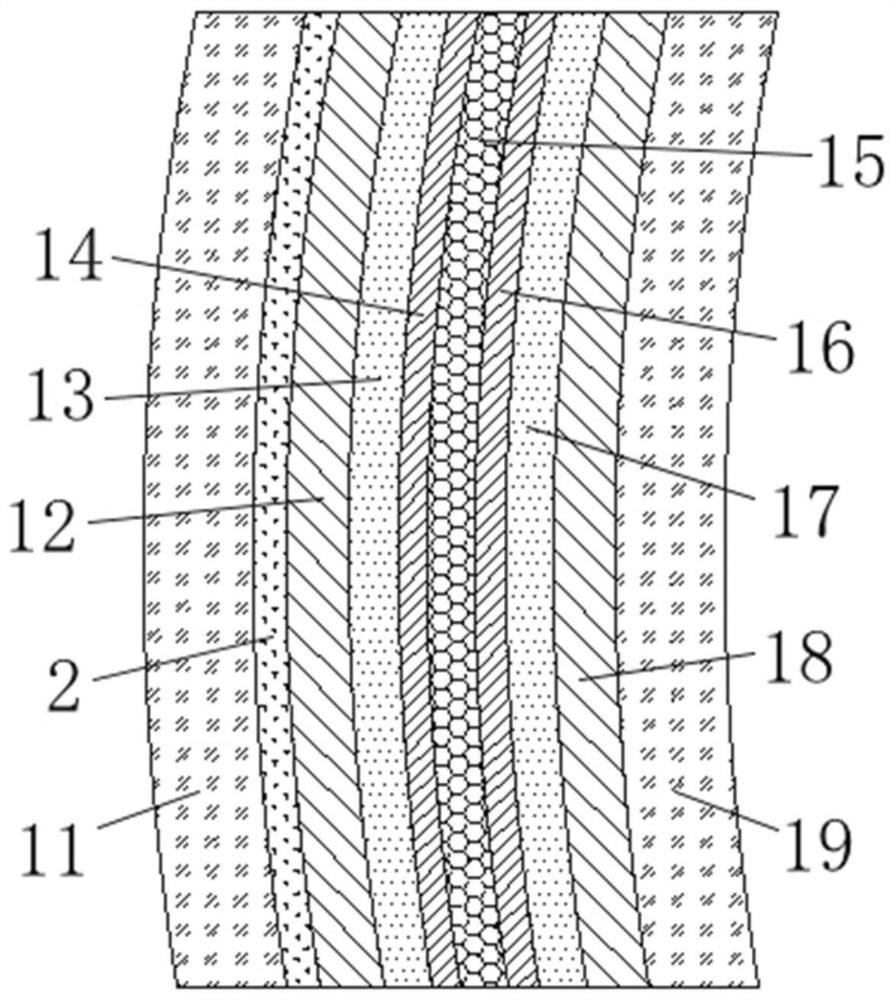

Embodiment 1

[0107] Mix 10g BP-2 UV absorber, 10g U410 blue light absorber, 55g butyl acetate solvent, 0.15g dibutyltin dilaurate catalyst and 25g γ-methacryloxypropyltrimethoxysilane, keep the temperature at 100℃ Reflux and stir in the oil bath for 4 hours, and naturally cool down to room temperature to obtain the chelating agent U1;

[0108] 13.56g ethyl orthosilicate, 20g absolute ethanol, 30g isopropanol, 5.18g γ-methacryloxypropyltrimethoxysilane, 0.1g mass fraction of 10% nitric acid and 12.5g deionized water , stirred in a 40°C water bath for 60 minutes to obtain silica sol A1;

[0109] Weigh 15g of silica sol A1 and 1g of chelating agent U1, mix and stir for 120 minutes to obtain UV-blocking and anti-blue-light coating solution B1;

[0110] In a dust-free environment, weigh an appropriate amount of UV-blocking and anti-blue light coating solution B1, and apply it on the surface of the curved glass plate 1 with a wire bar applicator. After standing for leveling, use an infrared lam...

Embodiment 2

[0112] Mix 10g of BP-2 UV absorber, 10g of U420 blue light absorber, 55g of butyl acetate solvent, 0.15g of dibutyltin dilaurate catalyst and 25g of γ-methacryloxypropyl trimethoxysilane at a constant temperature of 100°C Reflux and stir in the oil bath for 4 hours, and naturally cool down to room temperature to obtain the chelating agent U2;

[0113] 13.56g ethyl orthosilicate, 22g absolute ethanol, 28g isopropanol, 5.18g γ-methacryloxypropyltrimethoxysilane, 0.1g mass fraction of 10% nitric acid and 12.5g deionized water , stirred in a 40°C water bath for 70 minutes to obtain silica sol A2;

[0114] Weigh 20g of silica sol A2 and 1.5g of chelating agent U2, mix and stir for 120 minutes to obtain UV-blocking and anti-blue-light coating solution B2;

[0115] In a dust-free environment, weigh an appropriate amount of UV-blocking and anti-blue light coating solution B2, and apply it on the surface of the curved glass plate 1 with a wire bar applicator. After standing for leveli...

Embodiment 3

[0117] Mix 10g BP-2 ultraviolet absorber, 10g Jiedeying 1226 blue light absorber, 55g butyl acetate solvent, 0.15g dibutyltin dilaurate catalyst and 25g γ-methacryloyloxypropyltrimethoxysilane, in Reflux and stir in a constant temperature oil bath at 100°C for 4 hours, then cool down to room temperature naturally to obtain chelating agent U3;

[0118] 13.56g ethyl orthosilicate, 25g absolute ethanol, 28g isopropanol, 5.18g γ-methacryloxypropyltrimethoxysilane, 0.1g mass fraction of 10% nitric acid and 12.5g deionized water , stirred in a 40°C water bath for 80 minutes to obtain silica sol A3;

[0119] Weigh 20g of silica sol A3 and 1.3g of chelating agent U3, mix and stir for 120 minutes to obtain UV-blocking and anti-blue-light coating solution B3;

[0120] In a dust-free environment, weigh an appropriate amount of UV-blocking and anti-blue-light coating solution B3, and apply it on the surface of the curved glass plate 1 with a wire bar applicator. After standing for leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com