Cation-conducting resin slurry, preparation method and application thereof

A technology of resin slurry and cation, which is applied in polyether coatings, final product manufacturing, electrolyte storage battery manufacturing, etc. It can solve the problems of complex preparation process and high interface resistance, and achieve the effect of simple configuration, improved conduction speed and convenient conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

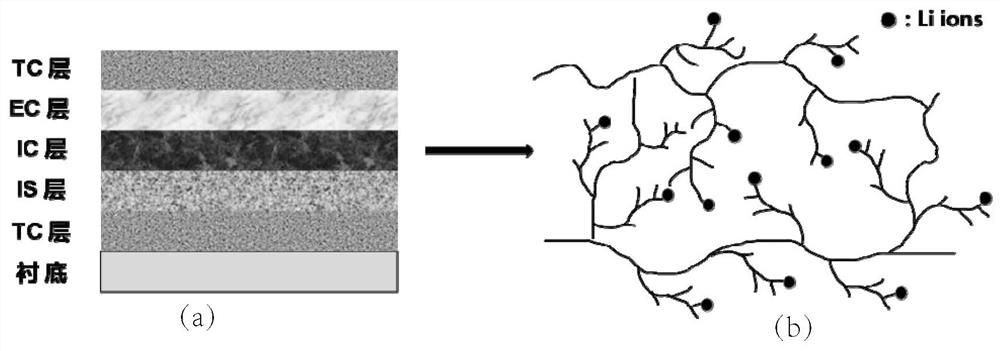

Method used

Image

Examples

Embodiment 1

[0061] First, configure the ion source solution, weigh lithium perchlorate and propylene carbonate at a mass ratio of 1:2, mix and stir thoroughly for 4-6 hours to form a clear and transparent solution, and store it away from light. Then weigh propylene glycol methyl ether acetate, photocurable resin UC-35 (Zhejiang Namei New Materials), stabilizer ferrocene, BYK1130, ETPTA and lithium ion according to the mass ratio of 2:1:1:0.1:1:1. solution, and stirred thoroughly for 30 minutes and then stored away from light. The configured solution is the resin slurry capable of conducting cations;

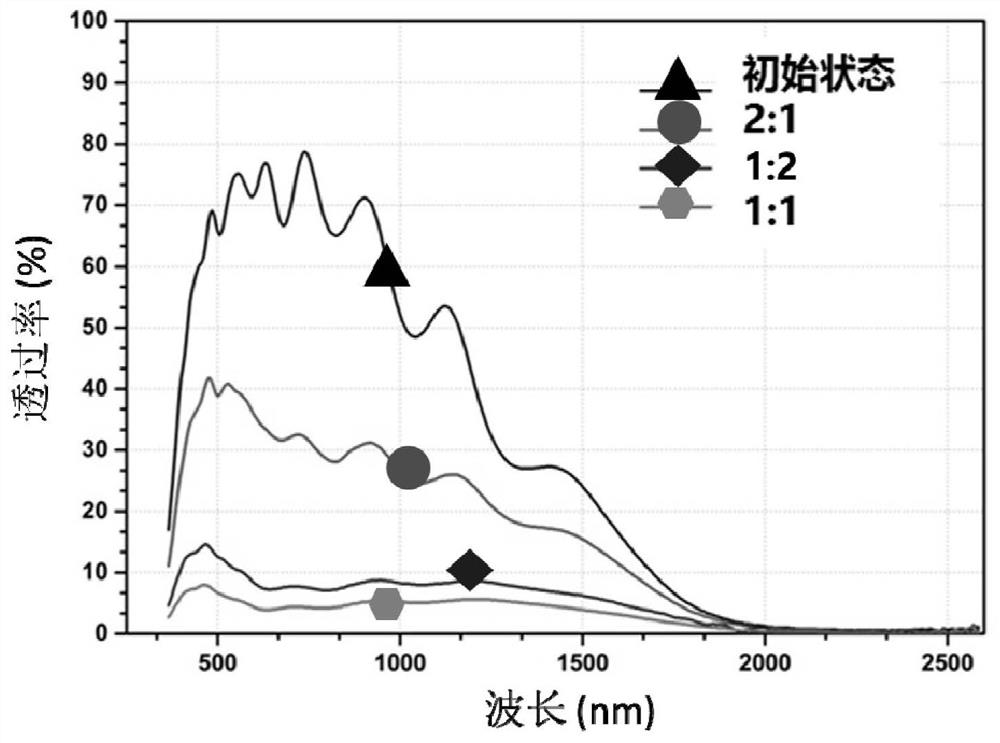

[0062] The obtained resin slurry capable of conducting cations was coated on the surface of the substrate, and uniformly irradiated with a 100W ultraviolet lamp for 15 minutes to obtain the resin film. The resulting resin film had a thickness of 80 µm. By judging the performance of electrochromism, embodiment 1 is the best performance.

Embodiment 2

[0064] First, configure the ion source solution, weigh lithium perchlorate and propylene carbonate at a mass ratio of 1:2, mix and stir thoroughly for 4-6 hours to form a clear and transparent solution, and store it away from light. Then weigh propylene glycol methyl ether acetate, polyethylene oxide with a molecular weight of 500,000, ferrocene, BYK1130, ETPTA and lithium ion solution according to the mass ratio of 2:1:1:0.1:1:1, and fully stir for 30 minutes to avoid light save. The prepared solution is the resin slurry capable of conducting cations.

Embodiment 3

[0066] First, configure the ion source solution, weigh sodium perchlorate and propylene carbonate at a mass ratio of 1:2, mix and stir thoroughly for 4-6 hours to form a clear and transparent solution, and store it away from light. Then weigh propylene glycol methyl ether acetate, photocurable resin UC-35, ferrocene, BYK1130, ETPTA and sodium ion solution according to the mass ratio of 2:1:1:0.1:1:1, and fully stir for 30 minutes before avoiding light save. The configured solution is the resin slurry capable of conducting cations;

[0067] The obtained resin slurry capable of conducting cations was coated on the surface of the substrate, and uniformly irradiated with a 100W ultraviolet lamp for 15 minutes to obtain the resin film. The resulting resin film had a thickness of 80 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com