Efficient method for extracting nickel sulfate from copper electrolysis waste liquid

A technology for electrolysis of nickel sulfate and copper, which is applied in the direction of nickel sulfate, copper sulfate, and the improvement of process efficiency, can solve the problems of increasing the processing cost of cathode copper and nickel sulfate, high failure rate of electro-evaporation equipment, and insufficient capacity of nickel removal system. , to avoid hidden dangers of production accidents, good cooling effect and high crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

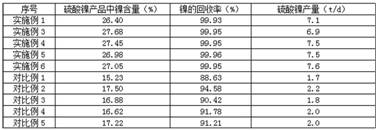

Examples

Embodiment 1

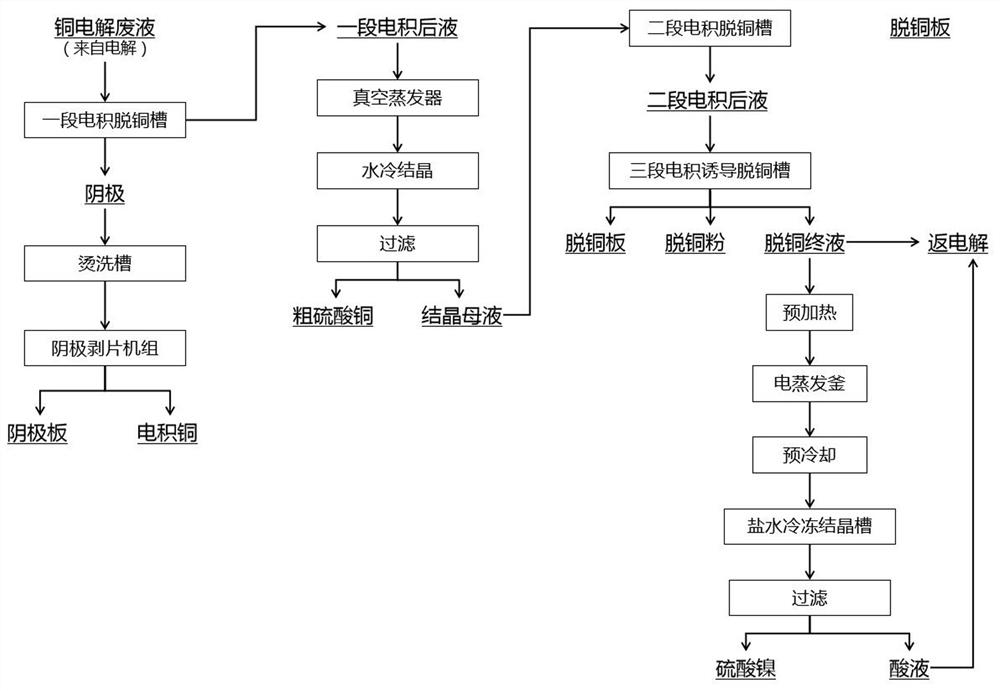

[0030] A kind of efficient method for extracting nickel sulfate from copper electrolysis waste liquid, it comprises the following steps:

[0031] (1) One-stage electrolytic copper production: Send the copper electrolytic waste liquid to the first-stage electrolytic decopper tank for electrolytic copper removal, send the cathode deposited with electrodeposited copper into the scalding tank for scalding, and then send it to the cathode Stripping unit to get electrodeposited copper and cathode plate;

[0032] (2) Production of crude copper sulfate: Send a section of electrowinning solution produced by a section of electrowinning copper removal tank to a vacuum evaporator for concentration to obtain a vacuum evaporated solution. The concentration temperature is 85°C, and then vacuum evaporated solution Carry out water-cooled crystallization, the temperature of the water-cooled crystallization is 35°C, and then filter and separate to obtain crude copper sulfate and crystallization ...

Embodiment 2

[0039] A kind of efficient method for extracting nickel sulfate from copper electrolysis waste liquid, it comprises the following steps:

[0040] (1) One-stage electrolytic copper production: Send the copper electrolytic waste liquid to the first-stage electrolytic decopper tank for electrolytic copper removal, send the cathode deposited with electrodeposited copper into the scalding tank for scalding, and then send it to the cathode Stripping unit to get electrodeposited copper and cathode plate;

[0041] (2) Production of crude copper sulfate: Send a section of electrowinning solution produced by a section of electrowinning copper removal tank to a vacuum evaporator for concentration to obtain a vacuum evaporated solution. The concentration temperature is 80°C, and then vacuum evaporated solution Carry out water-cooled crystallization, the temperature of the water-cooled crystallization is 25°C, and then filter and separate to obtain crude copper sulfate and crystallization ...

Embodiment 3

[0048] A kind of efficient method for extracting nickel sulfate from copper electrolysis waste liquid, it comprises the following steps:

[0049] (1) One-stage electrolytic copper production: Send the copper electrolytic waste liquid to the first-stage electrolytic decopper tank for electrolytic copper removal, send the cathode deposited with electrodeposited copper into the scalding tank for scalding, and then send it to the cathode Stripping unit to get electrodeposited copper and cathode plate;

[0050] (2) Production of crude copper sulfate: send a section of electrowinning solution produced by a section of electrowinning copper removal tank to a vacuum evaporator for concentration to obtain a vacuum evaporated solution. The concentration temperature is 90°C, and then vacuum evaporated solution Carry out water-cooled crystallization, the temperature of the water-cooled crystallization is 20°C, and then filter and separate to obtain crude copper sulfate and crystallization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com