Electrolyte and preparation method of magnesium alloy composite oxide black ceramic membrane

An electrolyte and magnesium alloy technology, applied in the field of metal surface treatment, can solve the problems of long electrolysis time, high power consumption of the process, rough surface of the film layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention does not specifically limit the preparation method of the electrolyte, which is a well-known preparation method in the art, and can be prepared by mixing.

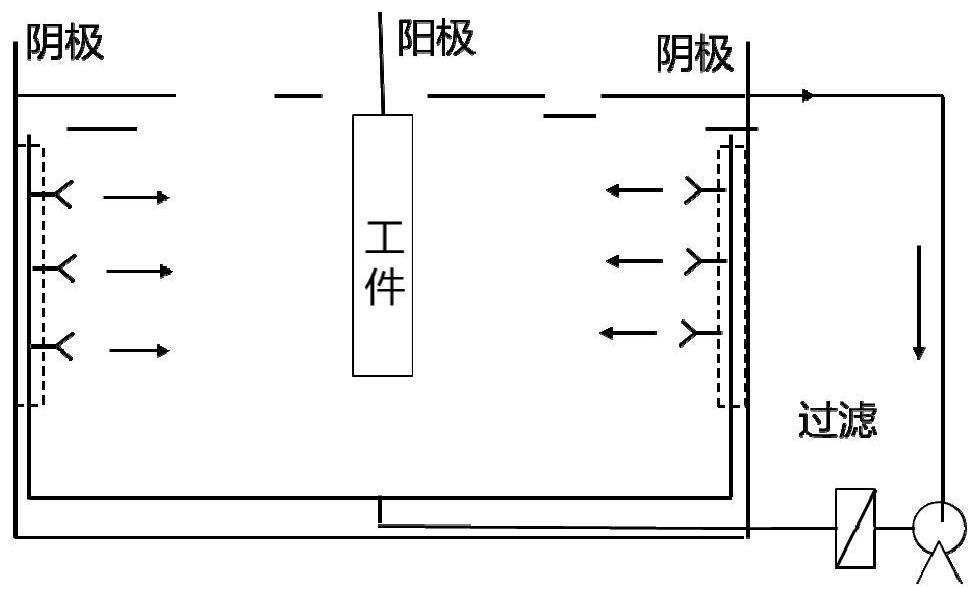

[0036] Such as figure 1 As shown, the second aspect of the present invention provides a kind of preparation method of magnesium alloy composite oxide black ceramic film as above, comprising:

[0037] The magnesium alloy is oxidized and electrolyzed using the electrolytic solution as described above to obtain the ceramic film.

[0038] In one embodiment, in the oxidation electrolysis of the present invention, the energization frequency is 100-1000 Hz, and the duty cycle is 5%-50%.

[0039] In one embodiment, in the oxidation electrolysis described in the present invention, the magnesium alloy is used as the anode, and the stainless steel is used as the cathode.

[0040] In one embodiment, the oxidation electrolysis time of the present invention is 1-30 min, preferably 1-10 min.

[0041] The p...

Embodiment 1

[0052] This example provides a kind of electrolytic solution, the preparation raw material of described electrolytic solution comprises: 20g / L potassium phosphate, 5g / L potassium hydroxide, 5g / L sodium metavanadate, 1g / L potassium permanganate, 2g / L Potassium ferrate, 50g / L triethanolamine, and water.

[0053] This example also provides the preparation method of electrolyte as above, including:

[0054] Add 20g / L potassium phosphate, 5g / L potassium hydroxide, and 5g / L sodium metavanadate into deionized water step by step, stir to dissolve, then add 1g / L potassium permanganate and 2g / L potassium ferrate , 50g / L triethanolamine obtains electrolytic solution.

[0055] This example also provides a method for preparing a magnesium alloy composite oxide black ceramic film, including:

[0056] After the magnesium alloy is pickled and washed in sequence, it is put into the above-mentioned electrolyte for oxidation electrolysis, washed with water and dried to obtain the ceramic film;...

Embodiment 2

[0058] This example provides an electrolyte solution, the preparation raw materials of the electrolyte solution include: 15g / L sodium phosphate, 2g / L potassium hydroxide, 10g / L sodium metavanadate, 1g / L potassium permanganate, 5g / L high iron sodium bicarbonate, 50g / L triethanolamine and water.

[0059] This example also provides the preparation method of electrolyte as above, including:

[0060] Add 15g / L sodium phosphate, 2g / L potassium hydroxide, and 10g / L sodium metavanadate into deionized water step by step, stir to dissolve, then add 1g / L potassium permanganate and 5g / L sodium ferrate , 50g / L triethanolamine obtains electrolytic solution.

[0061] This example also provides a method for preparing a magnesium alloy composite oxide black ceramic film, including:

[0062] After the magnesium alloy is pickled and washed in sequence, it is put into the above-mentioned electrolyte for oxidation electrolysis, washed with water and dried to obtain the ceramic film; in the oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com