Environment-friendly biomass antibacterial insect repellant and preparation method thereof

A technology of biomass and insect repellent, applied in the fields of botanical equipment and methods, animal repellents, chemicals for biological control, etc., can solve problems such as human health and environmental hazards, and achieve antibacterial and insect repellency The effect of good performance, high practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

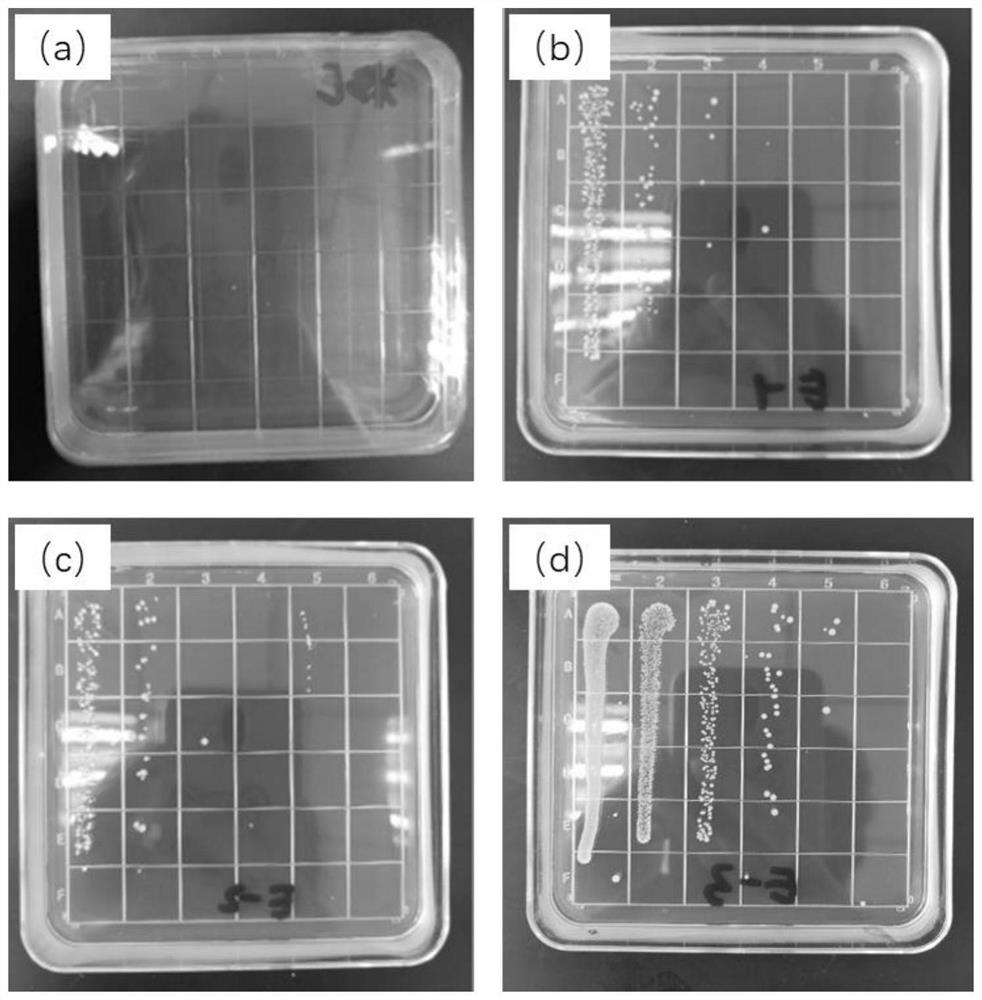

Image

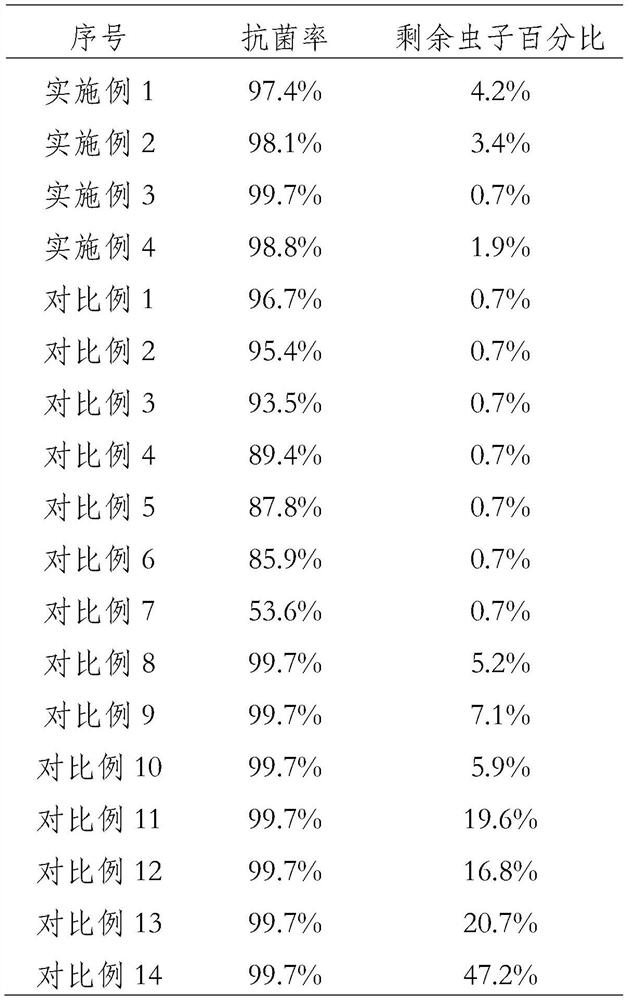

Examples

Embodiment 1

[0049] (1) According to the number of important parts, the raw materials are weighed as follows: 3 parts of nanoscale chitin, 6 parts of nanoscale kaolin, 2 parts of bamboo powder, 4 parts of mint amide derivatives, 2 parts of eucalyptus ethanol extract, 9 parts of citronella essential oil 8 parts of 3,8-terpineol, 4 parts of benzyl benzoate, 2 parts of glyceryl tristearate, 6 parts of tert-butyl p-hydroxyanisole, and 80 parts of solvent;

[0050] (2) Add 3 parts of nano-scale chitin, 6 parts of nano-scale kaolin, 2 parts of bamboo powder into the reaction kettle, add 80 parts of solvent, 500-1000 rpm, stir for 20-30 minutes until completely mixed;

[0051] (3) After complete mixing, continue to add 4 parts of menthyl amide derivatives, 2 parts of eucalyptus ethanol extract, 9 parts of citronella essential oil in the reaction kettle, stir for 10 minutes at 500-1000 rpm;

[0052] (4) Continue to add 8 parts of 3,8-terpinene diol and 4 parts of benzyl benzoate into the reaction ...

Embodiment 2

[0056] (1) According to the number of important parts, the raw materials are weighed as follows: 4 parts of nanoscale chitin, 6 parts of nanoscale kaolin, 3 parts of bamboo powder, 6 parts of mint amide derivatives, 2 parts of eucalyptus ethanol extract, 10 parts of citronella essential oil 9 parts of 3,8-terpineol, 5 parts of benzyl benzoate, 3 parts of glyceryl tristearate, 7 parts of tert-butyl p-hydroxyanisole, and 87 parts of solvent.

[0057] (2) Add 4 parts of nano-scale chitin, 6 parts of nano-scale kaolin, 3 parts of bamboo powder into the reaction kettle, add 87 parts of solvent, 500-1000 rpm, stir for 20-30 minutes until completely mixed;

[0058] (3) After complete mixing, continue to add 6 parts of menthyl amide derivatives, 2 parts of eucalyptus ethanol extract, 10 parts of citronella essential oil, 500-1000 rpm, and stir for 10 minutes in the reaction kettle;

[0059] (4) Continue to add 9 parts of 3,8-terpinene diol and 5 parts of benzyl benzoate into the react...

Embodiment 3

[0063] (1) According to the important parts, the raw materials are weighed as follows: 5 parts of nano-scale chitin, 7 parts of nano-scale kaolin, 4 parts of bamboo powder, 7 parts of mint amide derivatives, 3 parts of eucalyptus ethanol extract, 12 parts of citronella essential oil 10 parts of 3,8-terpinene diol, 6 parts of benzyl benzoate, 5 parts of glyceryl tristearate, 8 parts of tert-butyl p-hydroxyanisole, and 95 parts of solvent.

[0064] (2) Add 5 parts of nano-scale chitin, 7 parts of nano-scale kaolin, 4 parts of bamboo powder into the reaction kettle, add 95 parts of solvent, 500-1000 rpm, stir for 20-30 minutes until completely mixed;

[0065] (3) After being completely mixed, continue to add 7 parts of menthyl amide derivatives, 3 parts of eucalyptus ethanol extract, 12 parts of citronella essential oil, 500-1000 rpm, and stir for 10 minutes in the reaction kettle;

[0066] (4) Continue to add 10 parts of 3,8-terpinene diol and 6 parts of benzyl benzoate into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com