A kind of polypiperazinium functionalized anion exchange membrane and preparation method thereof

An anion exchange membrane, piperazinium technology, applied in the field of polypiperazine functionalized anion exchange membrane and its preparation, can solve the problems of high water absorption and swelling, poor dimensional stability, low ionic conductivity and the like, and improve the vanadium resistance performance. , good stability, high ion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

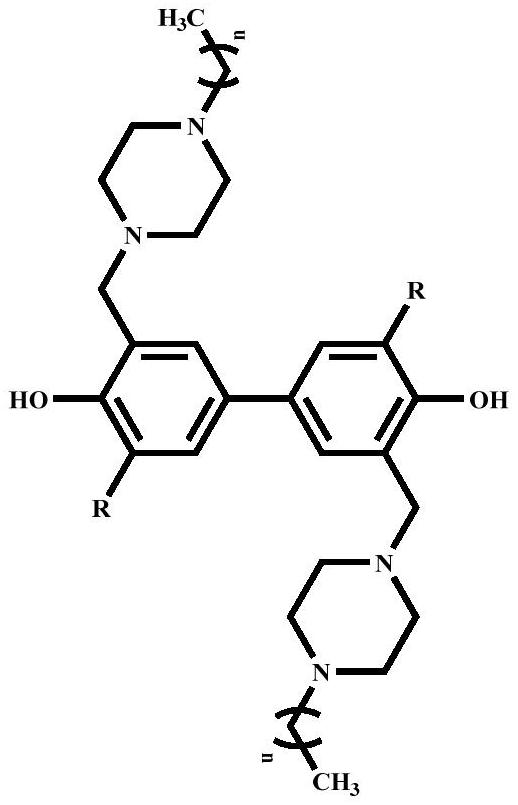

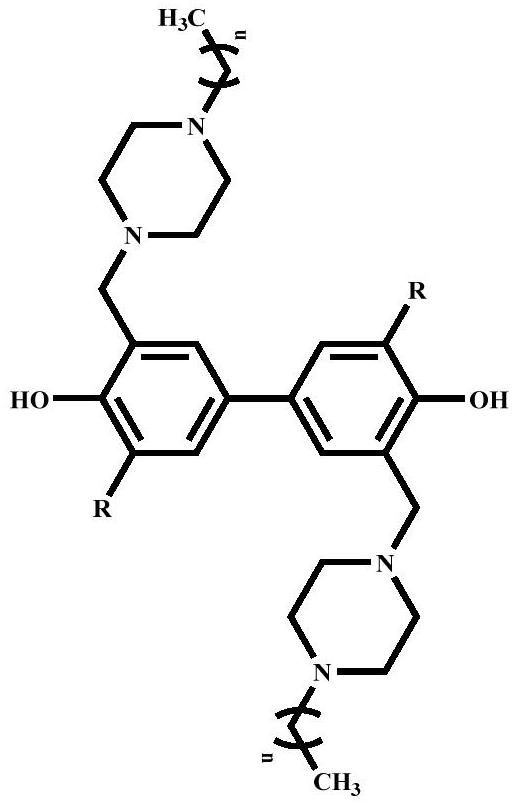

[0028] Synthesis of polypiperazinium functionalized 4,4'-biphenol: In a 250mL round bottom flask, 3.7242g (20mmol) of 4,4'-biphenol was dissolved in 40mL of ethanol, and after 1 hour, the reaction The container was placed in an ice bath, and after the reaction solution was lowered to 0° C., 4.0471 g (40 mmol) of N-methylpiperazine and 5.9 mL of formaldehyde in water were added. The solution was stirred at 25°C for 24 hours. The viscous solid was collected by rotary evaporation and washed several times with dichloromethane by rotary evaporation. It was recrystallized with ether, filtered, and dried under vacuum at 30°C for 12 hours to obtain off-white powder.

[0029] The obtained dopiperazinium-functionalized 4,4'-biphenol has the following structure (R is H; n=0):

[0030]

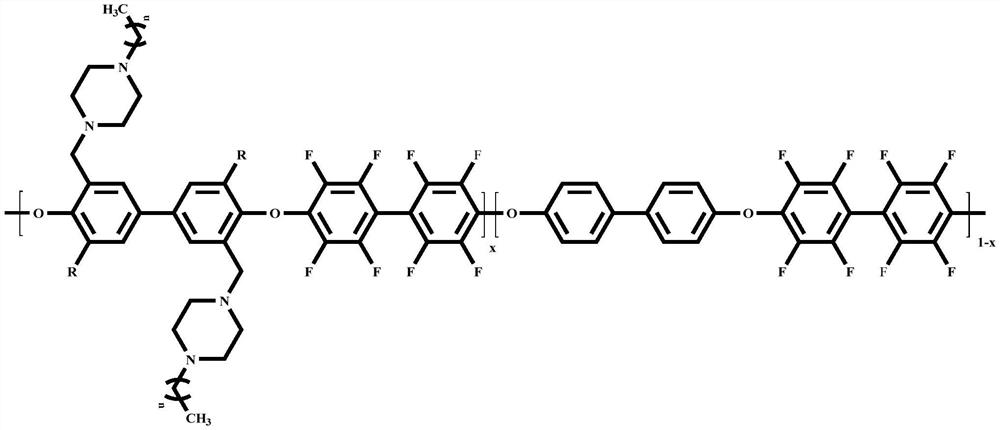

[0031] Synthesis of polypiperazinium functionalized polymer: under the protection of inert gas, 1.6424g (4mmol) of polypiperazinium functionalized 4,4'-biphenol, 3.3411g (10mmol) of decafluorobipheny...

Embodiment 2

[0038] Synthesis of polypiperazinium functionalized 4,4'-biphenol: same as Example 1

[0039] Synthesis of polypiperazinium functionalized polymer: under the protection of inert gas, 2.8742g (7mmol) of polypiperazinium functionalized 4,4'-biphenol, 3.3411g (10mmol) of decafluorobiphenyl and 0.5586 g (3 mmol) of 4,4'-biphenol was dissolved in DMAC, then 2.0732 g (15 mmol) of potassium carbonate was added, refluxed at 80°C for 6h to remove water, and then kept at a constant temperature of 85°C for 48h; the reaction solution Pour into deionized water to precipitate, filter, alternately wash several times with deionized water and ethanol, and dry to obtain a dopiperazinium functionalized polymer;

[0040]The quaternization of the polypiperazinium functionalized polymer: get the reaction product polymer 3.1809g (5mmol) obtained in the previous step and join in DMAC, stir to form a white emulsion, then add 1.9872g (14mmol) of methyl iodide respectively , at 45°C, the reaction time ...

Embodiment 3

[0046] Synthesis of polypiperazinium functionalized 4,4'-biphenol: same as Example 1

[0047] Synthesis of polypiperazinium functionalized polymer: under the protection of inert gas, 3.6954g (9mmol) of polypiperazinium functionalized 4,4'-biphenol, 3.3411g (10mmol) of decafluorobiphenyl and 0.1862 g (1 mmol) of 4,4'-biphenol was dissolved in DMAC, then 2.0732 g (15 mmol) of potassium carbonate was added, refluxed at 80°C for 6h to remove water, and then kept at a constant temperature of 85°C for 48h; the reaction solution Pour into deionized water to precipitate, filter, alternately wash several times with deionized water and ethanol, and dry to obtain a dopiperazinium functionalized polymer;

[0048] The quaternization of the polypiperazinium functionalized polymer: get the reaction product polymer 3.4093g (5mmol) obtained in the previous step and join in DMAC, stir to form a white emulsion, then add 2.5549g (18mmol) of methyl iodide respectively , at 45°C, the reaction time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com