Environment-friendly coating for indoor air pollution risk control and preparation method thereof

A technology for indoor air pollution and risk control, applied in the field of indoor air pollution risk management, can solve the problems of destroying the core components of coatings, difficulty in adjusting coating color, and discoloration of coatings, and achieve the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

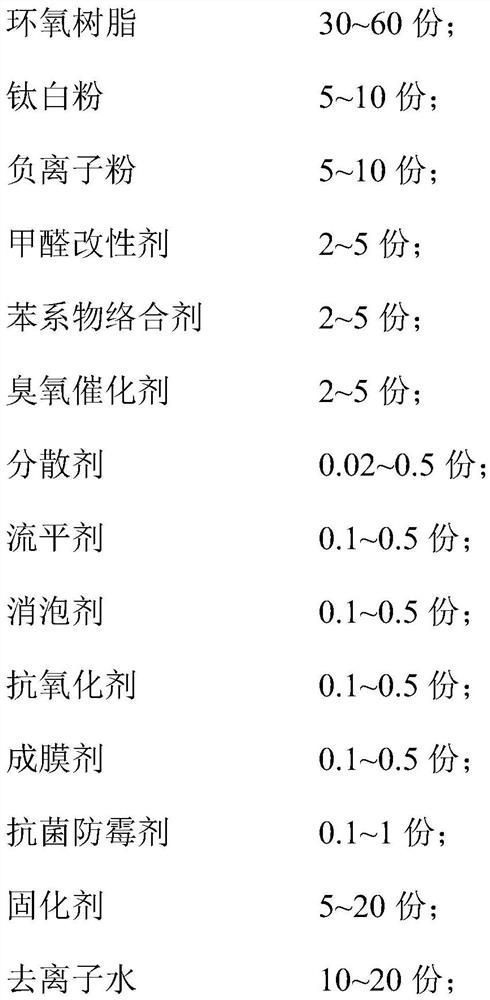

[0027] This embodiment provides a formula for an environmentally friendly paint used for indoor air pollution risk control, based on 100 parts by mass of the paint, including the following parts:

[0028]

[0029]

[0030] The preparation method of described coating comprises the following steps:

[0031] Step 1. Fully mix the formaldehyde modifier, benzene complexing agent, leveling agent, antioxidant, film forming agent, antibacterial and antifungal agent, and deionized water according to the number of components in the formula, and ultrasonically treat for 1 hour ;

[0032] Step 2, fully mix epoxy resin, titanium dioxide, negative ion powder, ozone catalyst, dispersant with the above-mentioned system according to the number of components in the formula, and ultrasonically treat for 1 hour;

[0033] Step 3: Fully mix the curing agent and defoamer with the above system according to the number of components in the formula, and fully stir for 1 hour with a conventional m...

Embodiment 2

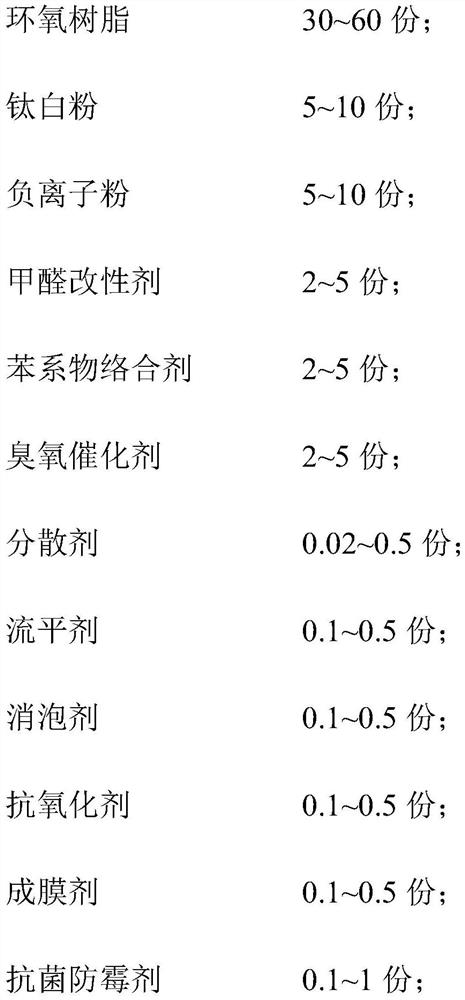

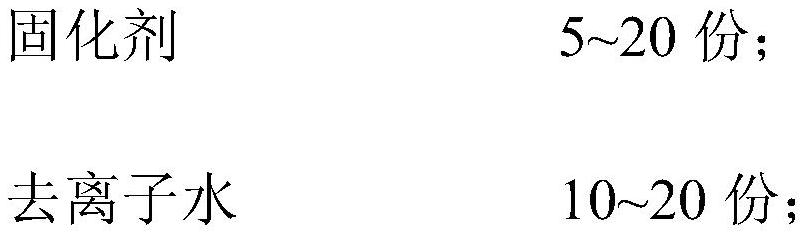

[0035] This embodiment provides a formula for an environmentally friendly paint used for indoor air pollution risk control, based on 100 parts by mass of the paint, including the following parts:

[0036]

[0037]

[0038] The preparation method of described coating comprises the following steps:

[0039] Step 1. Fully mix the formaldehyde modifier, benzene complexing agent, leveling agent, antioxidant, film forming agent, antibacterial and antifungal agent, and deionized water according to the number of components in the formula, and ultrasonically treat for 2 hours ;

[0040] Step 2, fully mix epoxy resin, titanium dioxide, negative ion powder, ozone catalyst, dispersant with the above-mentioned system according to the number of components in the formula, and ultrasonically treat for 2 hours;

[0041]Step 3: Fully mix the curing agent and defoamer with the above system according to the number of components in the formula, and fully stir for 2 hours with a conventional...

Embodiment 3

[0043] This embodiment provides a formula for an environmentally friendly paint used for indoor air pollution risk control, based on 100 parts by mass of the paint, including the following parts:

[0044]

[0045]

[0046] The preparation method of described coating comprises the following steps:

[0047] Step 1. Fully mix the formaldehyde modifier, benzene complexing agent, leveling agent, antioxidant, film forming agent, antibacterial and antifungal agent, and deionized water according to the number of components in the formula, and ultrasonically treat for 2 hours ;

[0048] Step 2, fully mix epoxy resin, titanium dioxide, negative ion powder, ozone catalyst, dispersant with the above-mentioned system according to the number of components in the formula, and ultrasonically treat for 2 hours;

[0049] Step 3: Fully mix the curing agent and defoamer with the above system according to the number of components in the formula, and fully stir for 2 hours with a conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com