Preparation process of oleyl alcohol polyoxyethylene ether sulfonate/sulfate

A technology of polyoxyethylene ether sulfonate and oleyl alcohol polyoxyethylene ether, which is applied in the field of preparation technology of oleyl alcohol polyoxyethylene ether sulfonate/sulfate, can solve the problems of polluting equipment, corrosion, restriction and the like, and achieves the Excellent salt tolerance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

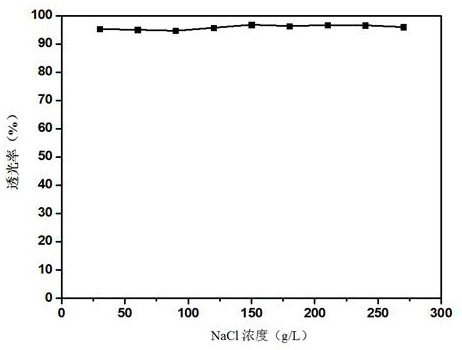

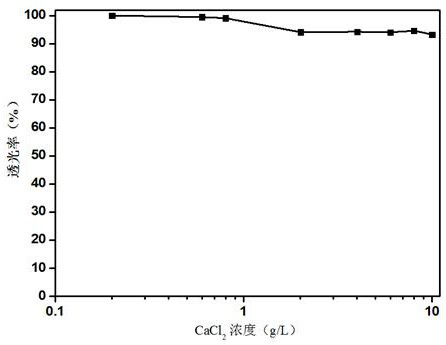

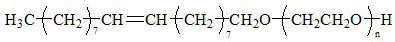

[0024] Oleyl ethoxylates (n = 2) with SO from sulfur combustion 3 / Air enters the sulfonation reactor from the top of the membrane sulfonator, SO 3 The gas volume concentration is 4.0%, the total moles of double bonds and alcoholic hydroxyl groups in oleyl alcohol polyoxyethylene ether and SO 3 The molar ratio is 1:1.01, the cooling water temperature of the jacket of the sulfonator is 40°C, the product flowing out from the bottom of the sulfonator is neutralized with NaOH aqueous solution, and then hydrolyzed at 100°C for 30min to obtain sodium oleyl alcohol polyoxyethylene ether sulfonate / sodium sulfate aqueous solution, the target product content accounts for 98.3% of the total solid content. 1g / L of the product in 0-250 g / L NaCl solution or 0-10 g / L CaCl 2 The solution remains clear, and the light transmittance remains above 90% (such as figure 1 and figure 2 shown), which can meet the needs of most high-salinity oil reservoirs in China. 1g / L of the product was hea...

Embodiment 2

[0026] Oleyl alcohol polyoxyethylene ether (n = 8) and SO from oleum stripping 3 / air mixed gas enters the sulfonation reactor from the top of the membrane sulfonator, SO 3 The gas volume concentration is 3.0%, the total moles of double bonds and alcoholic hydroxyl groups in oleyl alcohol polyoxyethylene ether and SO 3 The molar ratio is 1:1.10, the cooling water temperature of the jacket of the sulfonator is 70°C, the product flowing out from the bottom of the sulfonator is neutralized with KOH aqueous solution, and then hydrolyzed at 90°C for 120min to obtain potassium oleyl alcohol polyoxyethylene ether sulfonate / potassium sulfate aqueous solution, the target product content accounts for 95.7% of the total solid content.

Embodiment 3

[0028] Oleyl ethoxylates (n = 10) with liquid SO 3 SO by evaporation 3 / air mixed gas enters the sulfonation reactor from the top of the membrane sulfonator, SO 3 The gas volume concentration is 5.0%, the total moles of double bonds and alcoholic hydroxyl groups in oleyl alcohol polyoxyethylene ether and SO 3 The molar ratio is 1:1.05, the cooling water temperature of the jacket of the sulfonator is 80°C, the product flowing out from the bottom of the sulfonator is neutralized with NaOH aqueous solution, and then hydrolyzed at 90°C for 120min to obtain sodium oleyl alcohol polyoxyethylene ether sulfonate / sodium sulfate aqueous solution, the target product content accounts for 93.6% of the total solid content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com