Antibacterial temperature-regulating sarcandra glabra plant yarn, fabric and preparation method

A technology of plant antibacterial and grass coral fiber, which is applied in the field of textile fabrics, can solve the problems of comfort and protective application effect to be improved, and achieve the effect of filling market gaps, broadening categories and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a grass coral plant antibacterial temperature-regulating yarn, comprising the following steps:

[0030] Viscose-based grass coral fiber, viscose-based temperature-regulating fiber and cotton fiber are used as fiber raw materials for spinning to prepare grass-coral plant antibacterial temperature-regulating yarn;

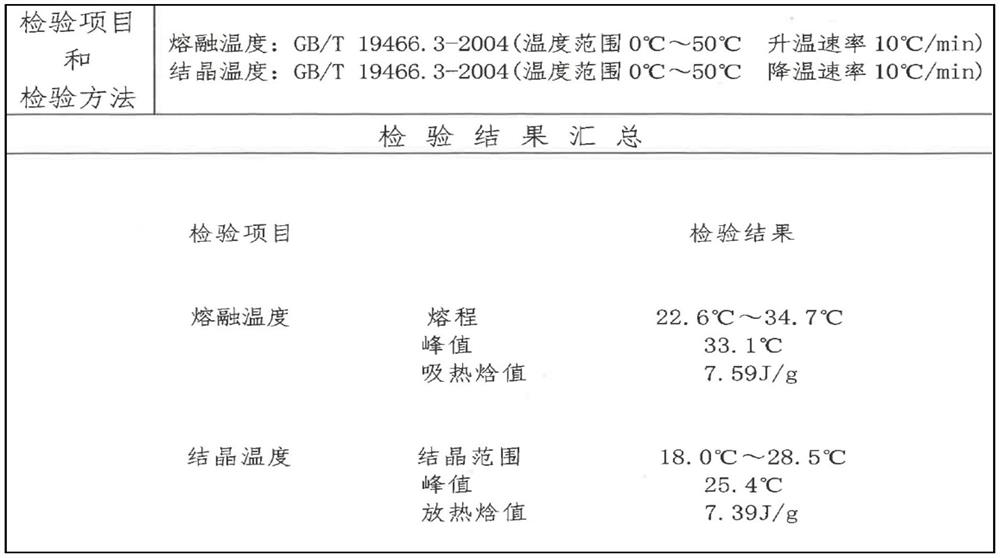

[0031] The mass ratio of the viscose-based grass coral fiber and viscose-based temperature-regulating fiber is 30-35:30-40; the viscose-based temperature-regulating fiber contains hydrocarbon wax wrapped in microcapsules, preferably Outlast viscose fiber, The specifications are 2.2dex, 3.3dex and 5dex, etc., and the lengths are 51mm, 60-110mm. Exemplarily, Outlast viscose fiber 1.7D*41mm is used in the embodiment of the present invention.

[0032] In the embodiment of the present invention, the combined blowing and carding machine can be used for spinning trial production. The specific process flow is: blowing and...

Embodiment 1

[0055] Embodiment 1 spinning process

[0056] Spray Outlast viscose fiber 1.7D*41mm with a mixture of 1.5% anti-slip agent and 1.5% water, balance for 24 hours and then form a bag; pre-mix Outlast viscose fiber, viscose-based grass coral fiber and combed cotton: Pack Outlast viscose fiber and combed sliver in a ratio of 80:20, and viscose-based grass coral fiber (grass coral@fiber product of Qingdao Bangte Fiber Co., Ltd.) and combed sliver in a ratio of 80:20 Into the disc for mixing production, and finally in the drawing process, the mixed Outlast fiber sliver, the mixed grass coral fiber sliver and the separate combed cotton sliver are mixed according to the ratio of 35 / 35 / 30.

[0057] Process flow: Blowing and mixing→carding→drawing (3 passes)→roving→spinning→winding, Siro compact spinning.

[0058] 1. Cleaning and carding process

[0059] The cleaning and carding process is based on the principle of short process, more carding, less beating, and slow speed, and the comb...

Embodiment 2

[0067] Embodiment 2 weaving process

[0068] On the knitting jacquard circular machine, the grass coral / outlast / cotton blended yarn of the 30 / 30 / 40 ratio of 40S in Example 1 is used to interweave into jacquard knitted double-sided cloth, with a grammage of 200g / m 2 , 32 needles, width 160cm.

[0069] Dyeing and finishing process: (wool) gray cloth → pretreatment → dyeing → dehydration → drying → setting → inspection; there is no special process requirement in the post-dyeing and finishing process, and it is carried out according to the conventional process.

[0070] The issues that need attention are as follows:

[0071] (1) The singeing of the fabric is carried out after dyeing, and the anti-pilling treatment is carried out during the scouring process.

[0072](2) The temperature during the scouring and bleaching process shall not exceed 100°C, and the amount of caustic soda shall not exceed 5g / L; the fabric shall not be mercerized or calendered.

[0073] (3) After finishi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com