Edge-doped crystalline silicon solar cell structure and production method thereof

A solar cell and edge technology, applied in the field of solar cells, can solve problems such as no good solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

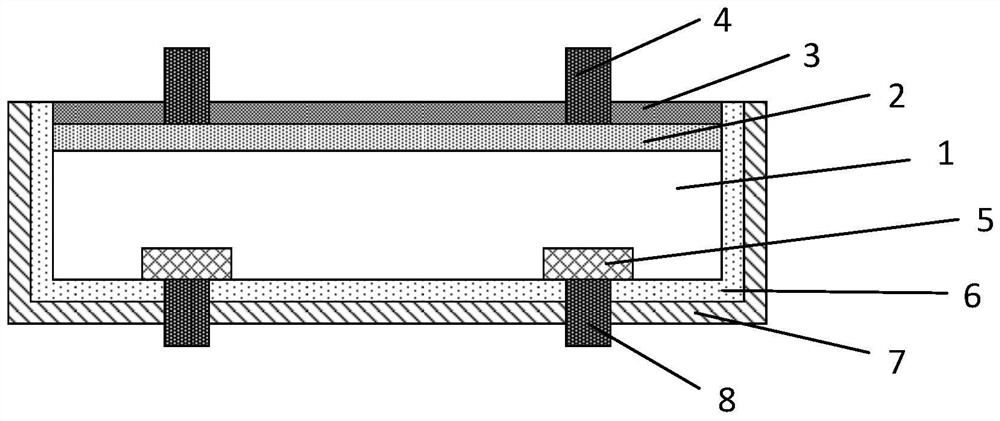

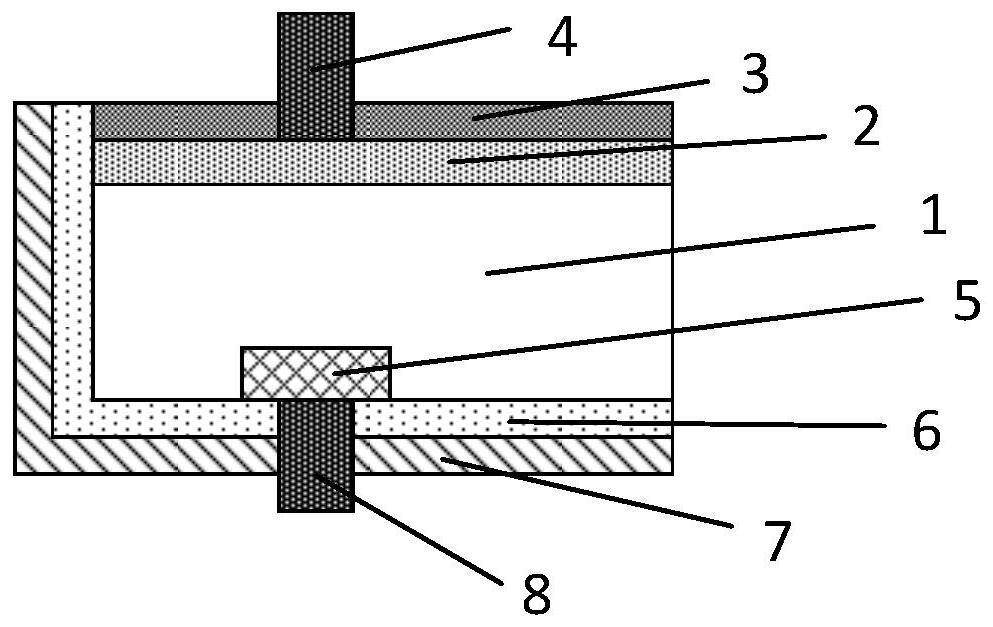

[0041] In order to solve the above problems, the present invention provides a crystalline silicon solar cell structure capable of reducing laser cutting edge loss and a preparation method thereof. For clarification, the present invention still uses figure 1 The p-type PERC battery is used as an example, but those skilled in the art can understand that the present invention is also suitable for n-type PERC batteries. According to the first embodiment of the present invention, as Figure 5 As shown, in the area to be cut by the laser (near the midline in the example of half cutting), the solid dopant source 9 is printed on the front side of the cell by screen printing. In one example, the dopant source 9 may be phosphorous. Alternatively, the dopant source can also be other materials suitable for heavily doping the edges, such as boron, gallium or a combination of these materials.

[0042] Subsequently, the solid dopant source 9 is irradiated with laser light. In one example...

Embodiment 2

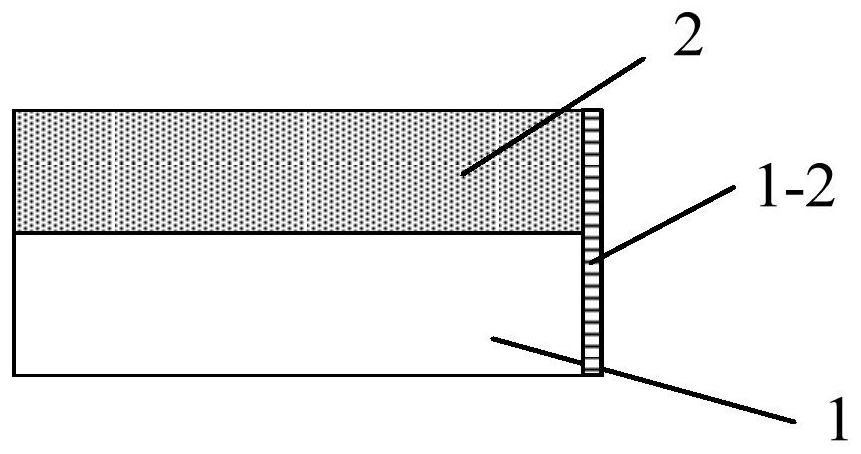

[0048] For clarification, the figure 1 Taking the p-type PERC battery as an example, according to the second embodiment of the present invention, the battery structure is firstly cut by laser, and after the laser cutting is completed, a half-sheet battery ( figure 2 ). Subsequently, by screen printing, a solid dopant source 9 (such as Figure 7 shown), and then irradiate the solid dopant source 9 with a laser, the laser generates heat, and the dopant atoms are doped into the silicon wafer 1, forming an edge heavily doped region 13 (such as Figure 9 shown). At this time, it turns out image 3 The 1-2 edge part in is heavily doped, and for this side p-n junction, the center of the junction region is moved from the original 1-2 to Figure 9 The interface between the middle silicon wafer 1 and the edge emitter 13 is far away from the laser-cut interface 1-2, thus reducing the influence of the region 1-2 on the overall recombination.

[0049] Alternatively or additionally, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com