Special high-specific-capacity high-nickel positive electrode material for solid-state battery and preparation method thereof

A cathode material and high specific capacity technology, which is applied in the field of high specific capacity and high nickel cathode materials for solid-state batteries and their preparation. It can solve the problem of design materials without solid-state battery characteristics, unsatisfactory performance of cathode materials, and less research on solid-state lithium-ion batteries. The problem is to reduce the washing time and the residual low-alkaline impurities on the surface, overcome the interfacial force of the solid phase, and reduce the processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a high-specific-capacity high-nickel positive electrode material for solid-state batteries, characterized in that it comprises the following steps:

[0037] 1) Ni x co y mn 1-x-y (OH) 2 Precursor, M a o b The oxide and lithium source are mixed according to a certain ratio and then added to a high-speed mixer. The speed of the high-speed mixer is 300-1000 rpm, and the mixing time is 30-60 minutes. After mixing, a mixture A is formed; wherein, 0.80≤x ≤0.98, 0.02≤y≤0.2, and 1-x-y>0, said M is one or more of Ti, Al, Mg, Zr, V, Sr, Ba;

[0038] 2) Place the mixture A in an oxygen atmosphere for the first step of calcination, first perform low-temperature calcination below 500°C, then raise the temperature to above 700°C for high-temperature calcination; then switch the atmosphere in the furnace to ammonia for etching Roasting, crushing and sieving to obtain mixture B;

[0039] 3) Mix mixture B and deionized water according to the mass ratio of 1:5...

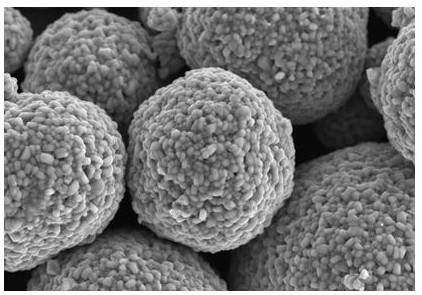

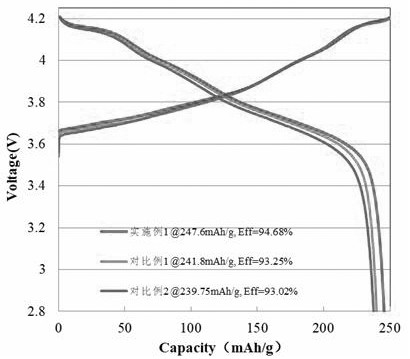

Embodiment 1

[0056] 1) Weigh 1kg of Ni 0.96 co 0.02 mn 0.02 (OH) 2 The precursor, 5g of titanium dioxide, and 500g of LiOH were mixed in a high-speed mixer at a speed of 1000 rpm for 45 minutes to form a mixed material A;

[0057] 2) Put the mixed material A in an atmosphere furnace for heat treatment, the roasting atmosphere is oxygen, treat at a low temperature of 400°C for 6 hours, then raise the temperature to 800°C, and after the treatment time is 15 hours, switch the roasting atmosphere in the atmosphere furnace to Ammonia, after roasting at 700°C for 2 hours, material B was obtained;

[0058] 3) Crushing and sieving the material B obtained in step 2), taking 500g of the sieved material and 5000g of pure water at a temperature of 40°C, stirring for 30 minutes and then filtering, and putting the filtered material into an oven at 100°C Material C was obtained after drying at ℃ for 4 hours;

[0059] 4) Take 400g of material C, add 2g of aluminum oxide and place it in an atmosphere ...

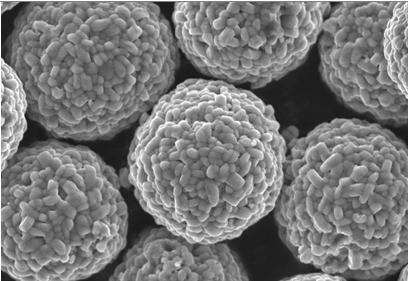

Embodiment 2

[0067] 1) Weigh 1kg of Ni 0.96 co 0.02 mn 0.02 (OH) 2 The precursor, 4g magnesium oxide, and 500g lithium carbonate were mixed in a high-speed mixer at a speed of 1000 rpm for 60 minutes to form a mixed material A;

[0068] 2) Put the mixed material A in an atmosphere furnace for heat treatment, the roasting atmosphere is oxygen, treat at a low temperature of 300°C for 5 hours, then raise the temperature to 800°C, and after the treatment time is 15 hours, switch the roasting atmosphere in the atmosphere furnace to Ammonia gas, after roasting at 800°C for 1 hour, material B was obtained;

[0069] 3) Crushing and sieving the material B obtained in step 2), taking 500g of the sieved material and 5000g of pure water at a temperature of 40°C, stirring for 30 minutes and then filtering, and putting the filtered material into an oven at 120 Material C was obtained after drying at ℃ for 4 hours;

[0070] 4) Take 400g of material C, add 2.5g of zirconia and place it in an atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com