Amorphous iron oxyhydroxide-biochar composite material and preparation method thereof

An iron oxyhydroxide, composite material technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as unfavorable large-scale integrated production, ethanol flammability problems such as the risk of increased preparation and the high price of ethanol solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of amorphous iron oxyhydroxide-biochar composite material, comprising the following steps:

[0023] Carbonizing the silica-containing biomass to obtain biochar material;

[0024] The biochar material is mixed with an aqueous iron salt solution, and a hydrothermal reaction is performed under alkaline conditions to obtain an amorphous iron oxyhydroxide-biochar composite material.

[0025] In the present invention, unless otherwise specified, the used preparation raw materials are all commercially available commodities well known to those skilled in the art.

[0026] In the present invention, the silica-containing biomass is carbonized to obtain a bio-char material. In the present invention, the content of silica in the silica-containing biomass is preferably 2%, more preferably 10%. In the present invention, the silica-containing biomass preferably includes one or more of corn stover, wheat stover and cotton stover.

[0027] ...

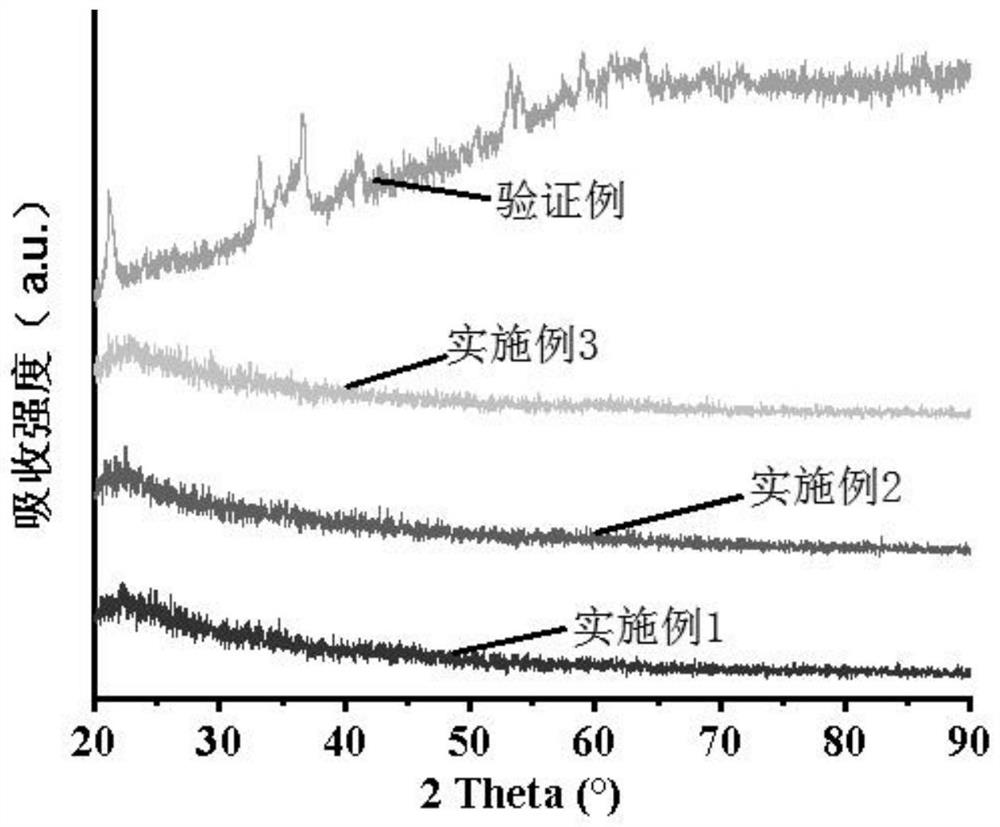

Embodiment 1

[0039] The corn stover with a silica content of 10% was pulverized to a particle size of 0.15 mm, washed with water, dried at 105 °C for 24 hours, heated at 600 °C for 2 hours, and carbonized; the obtained carbonized product was washed with water 8 times, Drying at 110°C for 24h to obtain biochar material;

[0040] The biochar material was put into an aqueous ferric nitrate solution with a mass concentration of 5 g / L, and the mass ratio of the biochar material to the ferric nitrate was 1:4, slowly stirred at 500 rpm for 24 hours, and added dropwise to the obtained mixed solution. Drop into the sodium hydroxide solution that concentration is 1mol / L, make the pH of solution be 12.03, transfer to the hydrothermal reaction still in 1min and carry out hydrothermal reaction, the temperature of hydrothermal reaction is 60 ℃, the pressure is 1MPa, and the time is 24h;

[0041] The product obtained after the hydrothermal reaction was washed with deionized water, then suction filtered, a...

Embodiment 2

[0043] The corn stover with a silica content of 10% was pulverized to a particle size of 0.15 mm, washed with water, dried at 105 °C for 24 hours, heated at 500 °C for 2 hours, and carbonized; the obtained carbonized product was washed with water 8 times, Drying at 110°C for 24h to obtain biochar material;

[0044] The biochar material was put into an aqueous ferric nitrate solution with a mass concentration of 5 g / L, and the mass ratio of the biochar material to the ferric nitrate was 1:4, slowly stirred at 500 rpm for 24 hours, and added dropwise to the obtained mixed solution. Drop into the sodium hydroxide solution that concentration is 1mol / L, make the pH of solution be 12.03, transfer to the hydrothermal reaction still in 1min and carry out hydrothermal reaction, the temperature of hydrothermal reaction is 60 ℃, the pressure is 1MPa, and the time is 24h;

[0045] The product obtained after the hydrothermal reaction was washed with deionized water, then suction filtered,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com