Microwave-assisted polypropylene grafting method

A polypropylene grafting and microwave-assisted technology, which is applied in the field of microwave-assisted polypropylene grafting, can solve the problems of easy sticking of reactants to the wall, low grafting rate and grafting efficiency, and uneven distribution of monomers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

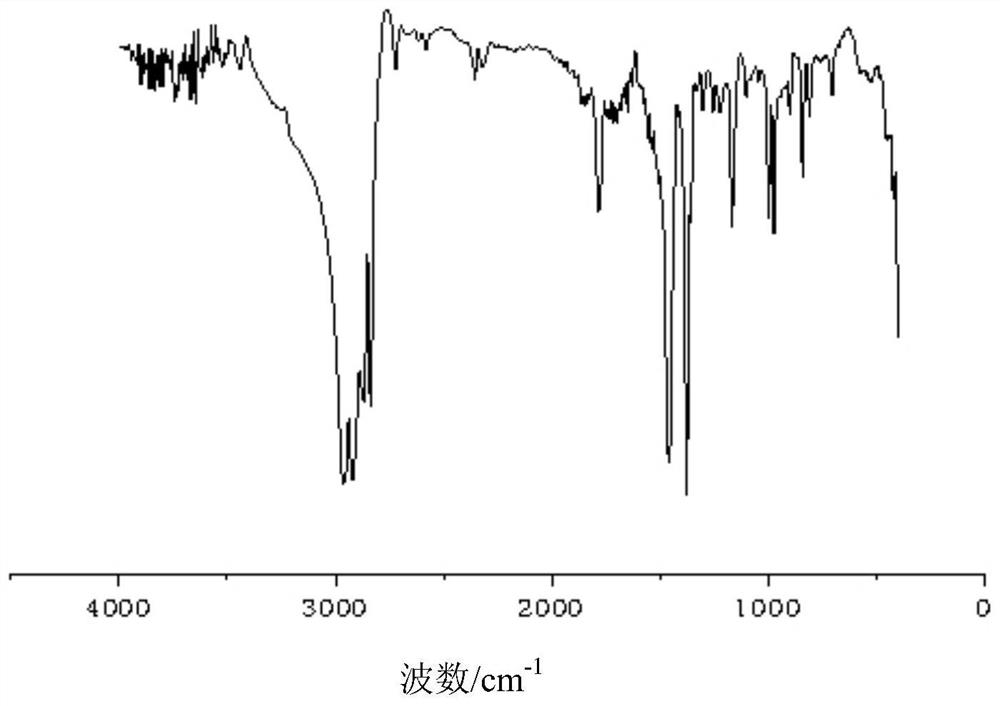

Image

Examples

Embodiment 1

[0035] Dissolve 0.0691g of benzoyl peroxide in 35mL of xylene, sonicate until it is completely dissolved, weigh 5.0154g of polypropylene and add it to xylene for swelling, continue to blow nitrogen into the swelling process, add 0.5105g of styrene and 0.5046g of maleic anhydride , heated with 480W microwave for 30min. After the reaction was completed and cooled to room temperature, the obtained product was extracted with acetone for 3 h, and dried at 60° C. to constant weight. The calculated grafting rate was 0.3555%.

Embodiment 2

[0037] Dissolve 0.0645g of benzoyl peroxide in 25mL of xylene and 10mL of ethylene glycol, sonicate until it is completely dissolved, weigh 5.0259g of polypropylene and add it to xylene for swelling. During the swelling process, nitrogen gas is continuously introduced, and 0.5154g of benzene is added. Ethylene and 0.5059g maleic anhydride were heated with 560W microwave for 30min. After the reaction was completed and cooled to room temperature, it was dried at 60° C. to a constant weight, and the calculated grafting rate was 1.3449%.

Embodiment 3

[0039] Dissolve 0.0642g of benzoyl peroxide in 29.2mL of xylene and 5.8mL of 1,4-butanediol, sonicate until it is completely dissolved, weigh 5.0083g of polypropylene and add it to xylene for swelling, and continue to blow nitrogen gas during the swelling process , add 0.5130g styrene and 0.5135g maleic anhydride, heat with 640W microwave for 30min. After the reaction was completed and cooled to room temperature, it was dried at 60° C. to a constant weight, and the calculated grafting rate was 1.6306%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com