Method for testing tension sensitivity of stress self-sensing cement-based material

A technology of cement-based materials and testing methods, which is applied in the directions of material resistance, testing material strength by applying stable tension/pressure, and preparation of samples for testing, etc. low problems, to achieve the effect of high stability, good compatibility and combination, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

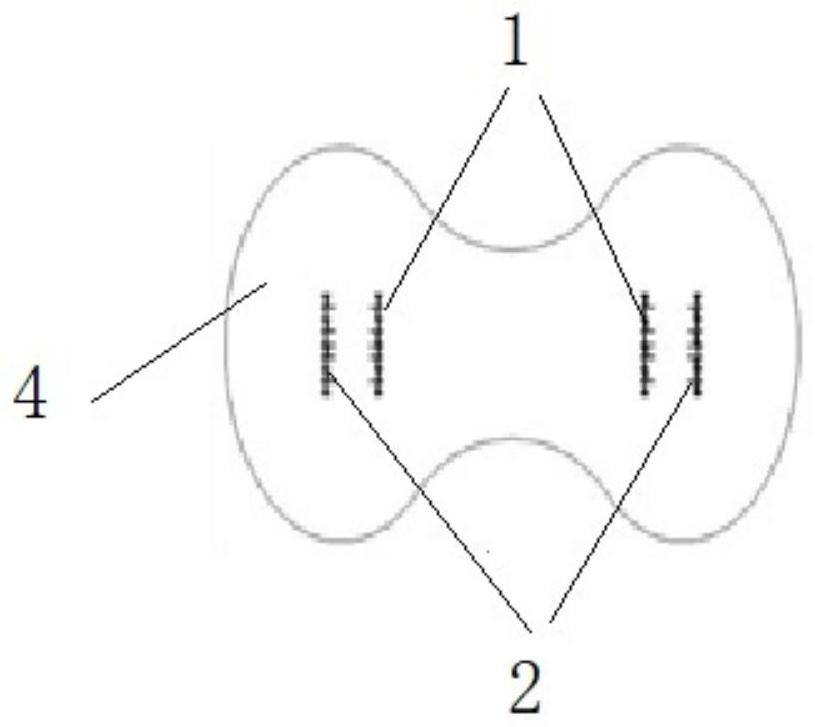

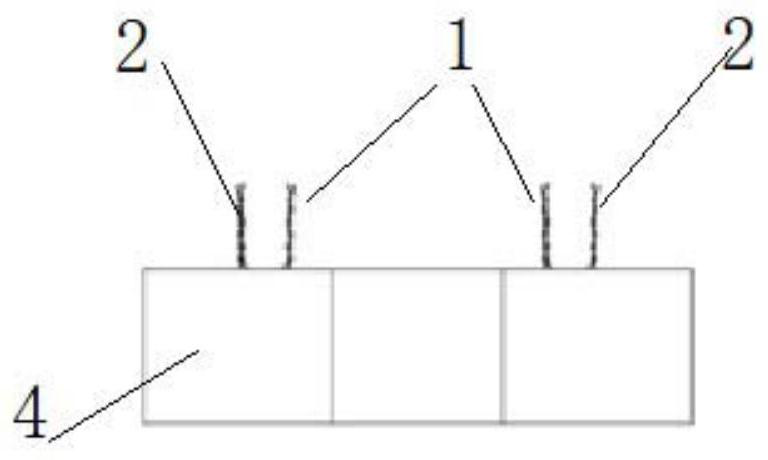

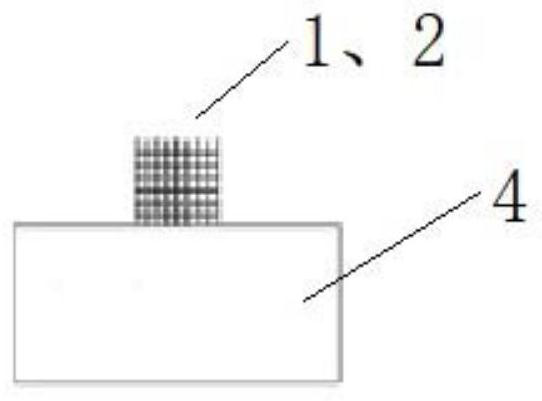

[0051] S1: if figure 1 , 2 As shown in , 3, prepare the cement paste and pour it into the "8" mold to ensure that the paste has good and almost uniform fluidity during the preparation of the test block 4. Insert four pieces of mesh metal electrodes into the cement slurry in a parallel arrangement, two first electrodes 1 on the inner side, and two second electrodes 2 on the outer side. After 28 days of curing, the structure of test block 4 is as follows figure 1 , 2 , 3 shown.

[0052] S2: Adjust the Keithley 2700 six and a half digit data acquisition multimeter test mode to two-electrode resistance test, connect two of the test lines to the two first electrodes 1 inside the test block 4, measure and record the distance between the two first electrodes 1 on the inside The resistance R 1 .

[0053] S3: Place the test block 4 in the fixture of the electronic universal testing machine, keep the upper and lower fixtures aligned and fix the test block 4 well, and perform an ax...

Embodiment 2

[0055] S1: The process of preparing the test block is as in Example 1.

[0056] S2: Adjust the Keithley 2700 6.5-digit data acquisition multimeter test mode to four-electrode resistance test. The four test lines are respectively connected to the inner and outer four electrodes according to the four-electrode resistance test method. Use the Keithley 2700 6.5-digit data acquisition multimeter to test the inner two electrodes The resistance R 1 .

[0057] S3: Place the test block in the fixture of the electronic universal testing machine, keep the upper and lower fixtures aligned and fix the test block well, and perform axial tensile test on the test block, apply a maximum tensile force of 300N, and the loading speed is 0.3mm / min, during the process of tension loading, the resistance R between two electrodes is collected in real time 2 , the calculation and evaluation process are the same as in Example 1.

Embodiment 3

[0059] S1: The process of preparing the test block is as in Example 1.

[0060] S2: Connect the two test wires equipped with the TH2810D LCR digital bridge to the two inner electrodes, and collect the initial resistance R 1 .

[0061] S3: Place the test block in the fixture of the electronic universal testing machine, keep the upper and lower fixtures aligned and fix the test block well, and perform axial tensile test on the test block, apply a maximum tensile force of 350N, and the loading speed is 0.35mm / min, during the process of tension loading, the resistance R between two electrodes is collected in real time 2 , the calculation and evaluation process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com