A preparation method of an integrated positive electrode with an efficient reaction interface in a composite zinc-air battery

A zinc-air battery and reaction interface technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc., to achieve good gas-phase transport, reduce charging voltage, and optimize uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific operation steps for the preparation of an integrated positive electrode with a high-efficiency reaction interface in a composite zinc-air battery are as follows:

[0024] (1) Dissolve 0.05g of PTFE dispersion in 40mL of deionized water, stir for 5 minutes, and pour it into a 50mL hydrothermal kettle with a polytetrafluoroethylene liner;

[0025] (2) Place the integrated electrode in the hydrothermal kettle and completely submerge it in the precursor solution, close the hydrothermal kettle, and set the temperature at 100 o Under the condition of C, the water is heated for 0.5 hours;

[0026] (3) Take out the electrode after hydroheating, dry it in a vacuum environment for 1 hour, place it in a tube furnace, and heat it with 10 o The heating rate of C / min is raised to 300 o C, calcined for 1 hour under nitrogen atmosphere, and cooled to room temperature with the furnace to obtain the positive electrode of the battery.

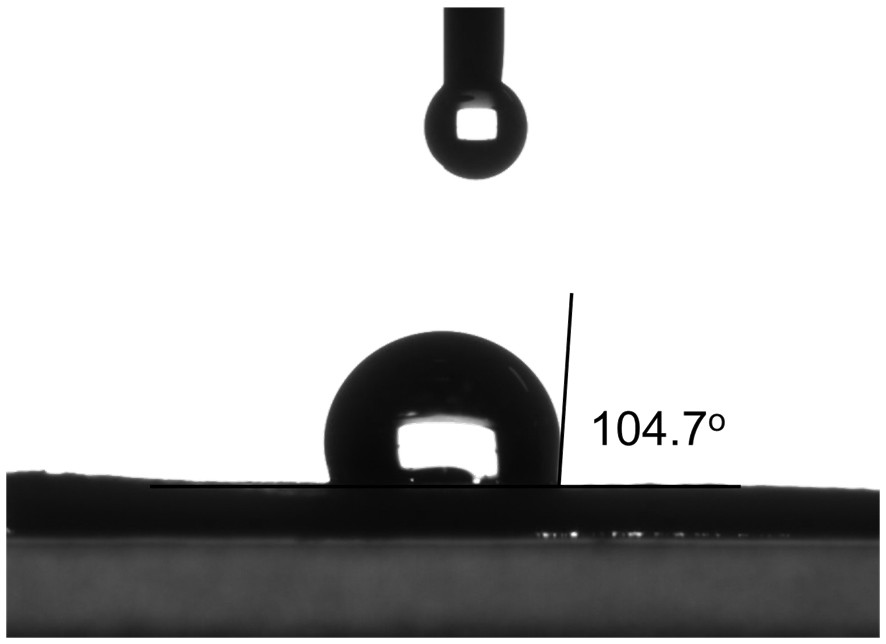

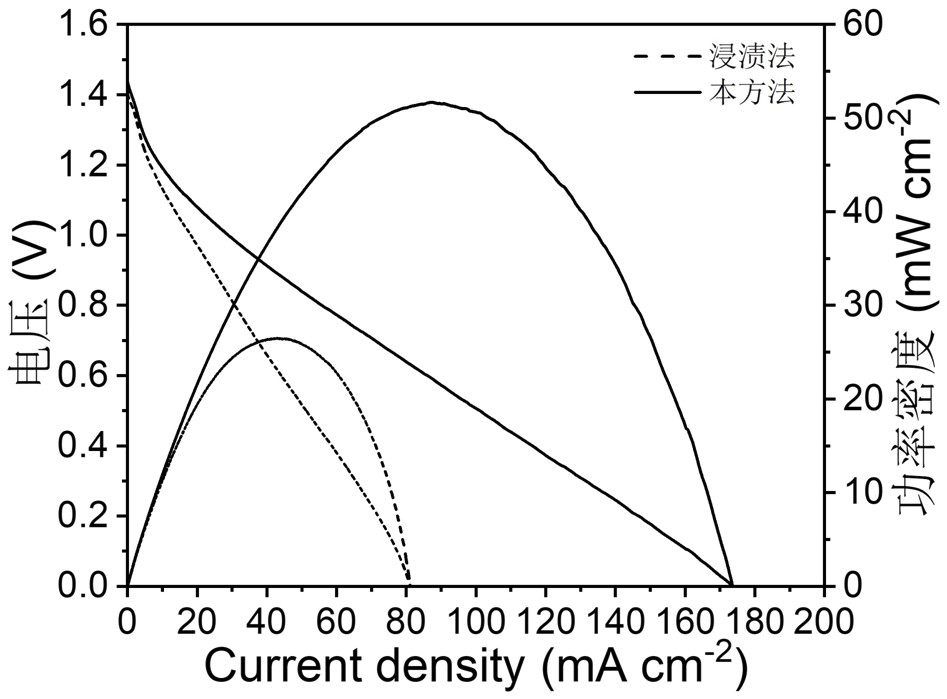

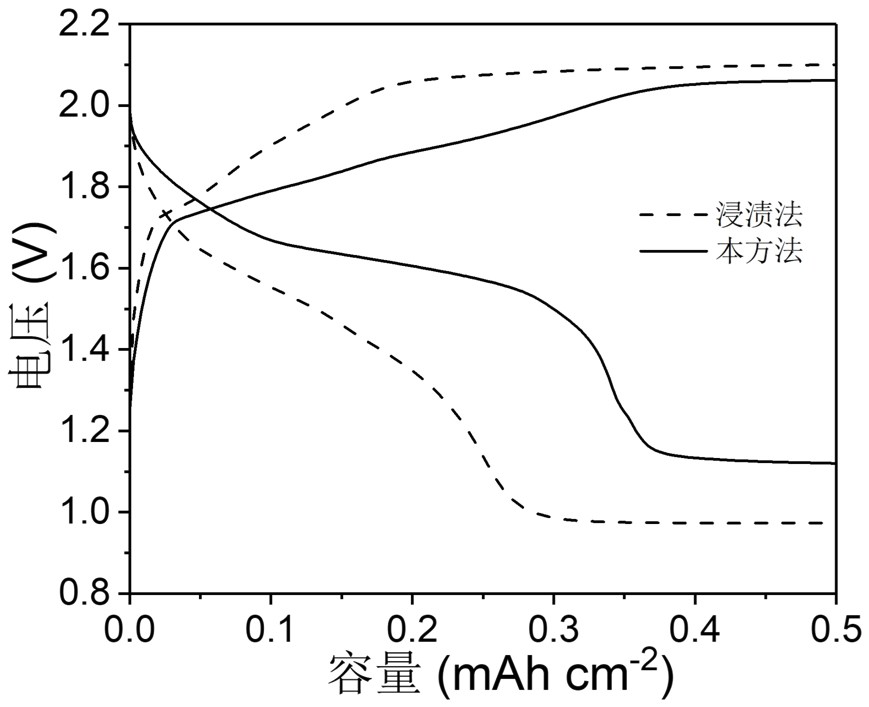

[0027] Electrodes are tested for hyd...

Embodiment 2

[0029] The specific operation steps for the preparation of an integrated positive electrode with a high-efficiency reaction interface in a composite zinc-air battery are as follows:

[0030] (1) Dissolve 0.05g of PTFE dispersion in 40mL of deionized water, stir for 5 minutes, and pour it into a 50mL hydrothermal kettle with a polytetrafluoroethylene liner;

[0031] (2) Place the integrated electrode in the hydrothermal kettle and completely submerge it in the precursor solution, close the hydrothermal kettle, and set the temperature at 100 o Under the condition of C, heat water for 1 hour;

[0032] (3) Take out the electrode after hydroheating, dry it in a vacuum environment for 1 hour, place it in a tube furnace, and heat it with 10 o The heating rate of C / min is raised to 300 o C, calcined for 1 hour under nitrogen atmosphere, and cooled to room temperature with the furnace to obtain the positive electrode of the battery.

[0033] The electrode is tested for hydrophilicity,...

Embodiment 3

[0035] The specific operation steps for the preparation of an integrated positive electrode with a high-efficiency reaction interface in a composite zinc-air battery are as follows:

[0036] (1) Dissolve 0.1g of PTFE dispersion in 40mL of deionized water, stir for 5 minutes, and pour it into a 50mL hydrothermal kettle with a polytetrafluoroethylene liner;

[0037] (2) Place the integrated electrode in the hydrothermal kettle and completely submerge it in the precursor solution, close the hydrothermal kettle, and set the temperature at 100 o Under the condition of C, heat water for 1 hour;

[0038] (3) Take out the electrode after hydroheating, dry it in a vacuum environment for 1 hour, place it in a tube furnace, and heat it with 10 o The heating rate of C / min is raised to 300 o C, calcined for 1 hour under nitrogen atmosphere, and cooled to room temperature with the furnace to obtain the positive electrode of the battery.

[0039] The electrode was tested for hydrophilicit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com