A kind of reactive dyeing wastewater treatment method and concentrated liquid color paste

A reactive dyeing and wastewater treatment technology, which is applied in textile industry wastewater treatment, dyeing method, water/sewage treatment, etc., can solve the problems of decreased activity of dyes, inability to realize resource utilization of dyes, failure to achieve effective separation of dyes and inorganic salts, etc. , to achieve the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

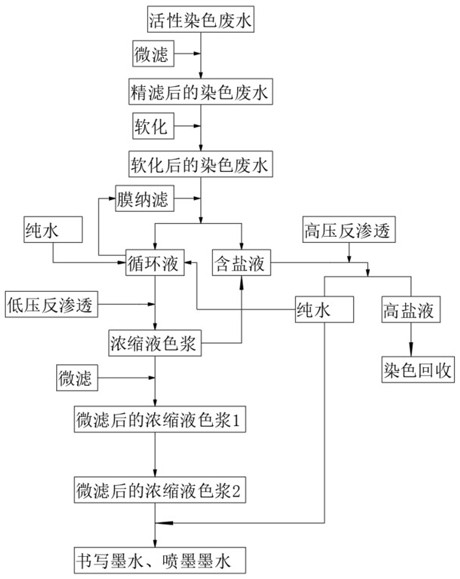

Image

Examples

Embodiment 1

[0060] Objects to be treated: 5 tons of reactive yellow 176 dyeing wastewater with a chroma of 4000, a salt content of 4.5% (NaCl is 3%, Na2SO4 is 1.5%), pH=11, and a temperature of 60°C.

[0061] First, it is filtered through a PP melt-blown filter element with a pore size of 0.2mm, and then softened by domestic 113 resin.

[0062] Add hydrochloric acid to adjust the pH=6, and enter the PRo-CEMÒ NF nanofiltration system with a surface area of 5 square meters for desalination, the operating pressure is 5.0Bar, and add pure water in 5 times, 2.5 tons each time. After passing through nanofiltration, circulating liquid and saline liquid are formed.

[0063] The circulating liquid is concentrated by a low-pressure reverse osmosis membrane, and the pressure is 30Bar to obtain 110 kg of concentrated liquid color paste with a concentration of 22.5%; the dye recovery rate is 99.1%; the chloride ion content is 35ppm, the sulfate content is 43ppm, and the calcium ion content is 5ppm a...

Embodiment 2

[0065] The object of the treatment of embodiment one is to change the reactive dyeing waste water of active red 239; Pure water water production rate 80%, other conditions are constant, finally obtain concentration and be 105 kilograms of concentrated liquid color pastes of 19.5%, dyestuff recovery rate 98.8% According to the chloride ion content 58ppm of dyestuff percentage, sulfate radical content 30ppm, calcium ion content 2ppm, magnesium ion content is not detected; Produce about 2.6 tons of high-salt liquid of 8.6% salt content, high-salt liquid chromaticity 78.

Embodiment 3

[0067] The processing object of embodiment one is changed into or active dark blue 203, other conditions are constant, finally obtain concentration and be 85 kilograms of concentrated liquid color pastes of 25.2%, dyestuff recovery rate 99.2%, according to the chloride ion content 44ppm of dyestuff percentage, The sulfate content is 35ppm, the calcium ion content is 8ppm, and the magnesium ion content is 2ppm; about 1.65 tons of high-salt liquid with a salt content of 13.5% is produced, and the color of the high-salt liquid is 90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com