Lignin fiber aerogel as well as preparation method and application thereof

A technology of lignin fibers and aerogels, which is applied in the chemical characteristics of fibers, textiles and papermaking, hybrid capacitor electrodes, etc., can solve the problems of flammability and explosion of electrospinning devices, and achieve the effect of saving costs and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

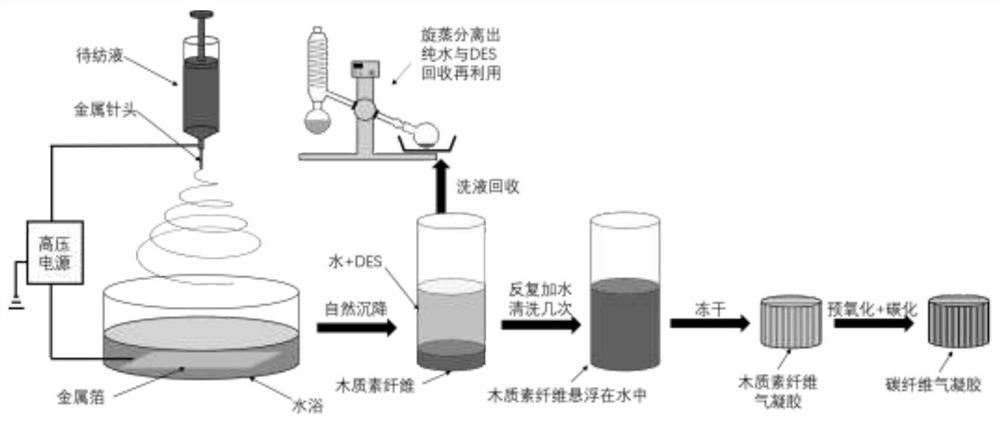

[0027] The present invention provides a kind of preparation method of lignocellulosic airgel, the method comprises:

[0028] Step 1: Use a deep eutectic solvent to dissolve the linear polymer, and after mixing evenly, continue to dissolve the lignin to form a uniform solution as the electrospinning solution;

[0029] Described deep eutectic solvent is choline chloride base deep eutectic solvent or betaine base deep eutectic solvent; Described chloride choline base deep eutectic solvent is preferably choline chloride and malic acid, oxalic acid or A mixture of lactic acids. In the mixture of choline chloride and malic acid, oxalic acid or lactic acid, the molar ratio of choline chloride to malic acid, oxalic acid or lactic acid is preferably 1:2-10.

[0030] The betaine deep eutectic solvent is a mixture of betaine and lactic acid or malic acid; in the mixture of betaine and lactic acid or malic acid, the molar ratio of betaine and lactic acid or malic acid is preferably 1:2 ...

Embodiment 1

[0041] (1) Use the choline chloride-lactic acid deep eutectic solvent to dissolve the polyvinyl alcohol polymer, and after mixing evenly, continue to dissolve the lignin to form a uniform solution as the spinning solution for electrospinning. The mass ratio of deep eutectic solvent, polyvinyl alcohol, and lignin is 1:0.02:0.1, and the molar ratio of choline chloride and lactic acid in choline chloride-lactic acid is 1:2.

[0042] (2) Use a plastic syringe to inhale the spinning solution prepared in step (1), install a metal needle, set up the electrospinning device vertically, and spray filaments downward. The plastic basin filled with water is used as the receiving device (water bath) below, and the inside is covered with metal foil and grounded, and the stirring bar is placed under the water to stir slowly during the electrospinning process. The needle is 10cm above the water surface. During the electrospinning process, the voltage was set at 15 kV, the temperature was 25 °...

Embodiment 2

[0046] (1) Use the betaine-lactic acid deep eutectic solvent to dissolve the polyvinylpyrrolidone macromolecule, and after mixing evenly, continue to dissolve the lignin to form a uniform solution as the spinning solution for electrospinning. The content mass ratio of deep eutectic solvent, polyvinylpyrrolidone and lignin is 1:0.02:0.15, wherein the molar ratio of betaine and lactic acid in betaine-lactic acid is 1:2.

[0047] (2) Use a plastic syringe to inhale the spinning solution prepared in step (1), install a metal needle, set up the electrospinning device vertically, and spray filaments downward. The plastic basin filled with water is used as the receiving device (water bath) below, and the inside is covered with metal foil and grounded, and the stirring bar is placed under the water to stir slowly during the electrospinning process. The needle is 10cm above the water surface. During the electrospinning process, the voltage was set at 15 kV, the temperature was 25 °C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com