Composite biological water purifying agent and preparation method thereof

A water purifying agent and composite technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of performance stability, economic applicability and industrial application of treatment methods Meet other problems, to achieve the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

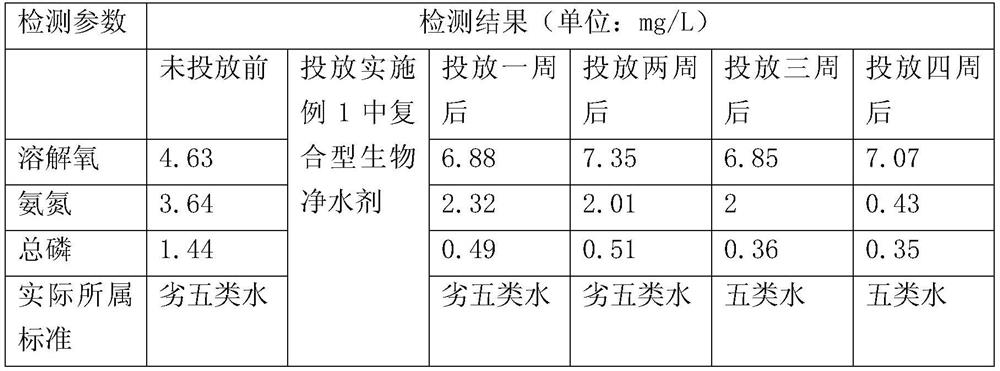

Embodiment 1

[0026] A composite biological water purifier, its formula is: 30 parts of modified porous natural stone particles, 25 parts of air oxidation iron removal filter drying residue and 5 parts of microbial flora.

[0027] The preparation method of this composite type biological water purifying agent is:

[0028] (1) Preparation of modified porous natural stone particles: take the modified porous natural stone particles, add concentrated sulfuric acid according to 30% of the weight of the porous natural stone particles, wherein the concentrated sulfuric acid is best added dropwise, after fully stirring and cooling for later use ;

[0029] (2) Air oxidative deironing and filtering dry slag, when using calcium oxide as a neutralizing agent to carry out air oxidative deironing by the soot leaching solution and / or zinc concentrate leaching solution of the wet zinc smelting plant, the obtained air oxidative deironing residue enters the filter, Made after drying. The air oxidation deiro...

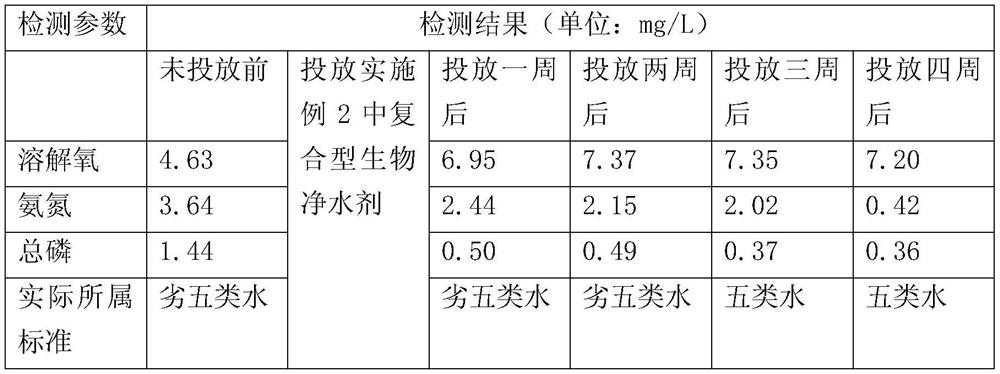

Embodiment 2

[0033] A compound biological water purifying agent, its formula is: 40 parts of modified porous natural stone particles, 15 parts of air oxidation iron removal filter drying residue and 12 parts of microbial flora.

[0034] The preparation method of this composite type biological water purifying agent is:

[0035] (3) Preparation of modified porous natural stone particles: take the modified porous natural stone particles, add concentrated sulfuric acid according to 100% of the weight of the porous natural stone particles, wherein the concentrated sulfuric acid is best added dropwise, and it is ready to use after fully stirring and cooling ;

[0036] (4) Air oxidative deironing and filtering dry slag, when using calcium oxide as a neutralizing agent to carry out air oxidative deironing by the soot leaching solution and / or zinc concentrate leaching solution of the wet zinc smelting plant, the obtained air oxidative deironing residue enters the filter, Made after drying. The ai...

Embodiment 3

[0040] A compound biological water purifying agent, its formula is: 50 parts of modified porous natural stone particles, 20 parts of air oxidation iron removal filter drying residue and 5 parts of microbial flora.

[0041] The preparation method of this composite type biological water purifying agent is:

[0042] (5) Preparation of modified porous natural stone particles: take the modified porous natural stone particles, add concentrated sulfuric acid according to 60% of the weight of the porous natural stone particles, wherein the concentrated sulfuric acid is best added dropwise, and it is ready to use after fully stirring and cooling ;

[0043] (6) Air oxidative deironing and filtering dry slag, when using calcium oxide as a neutralizing agent to carry out air oxidative deironing by the soot leaching liquid and / or zinc concentrate leaching liquid of the wet zinc smelting plant, the obtained air oxidative deironing residue enters the filter, Made after drying. The air oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com