Preparation method and application of nano-silicon cross-linking agent and quick-response hydrogel

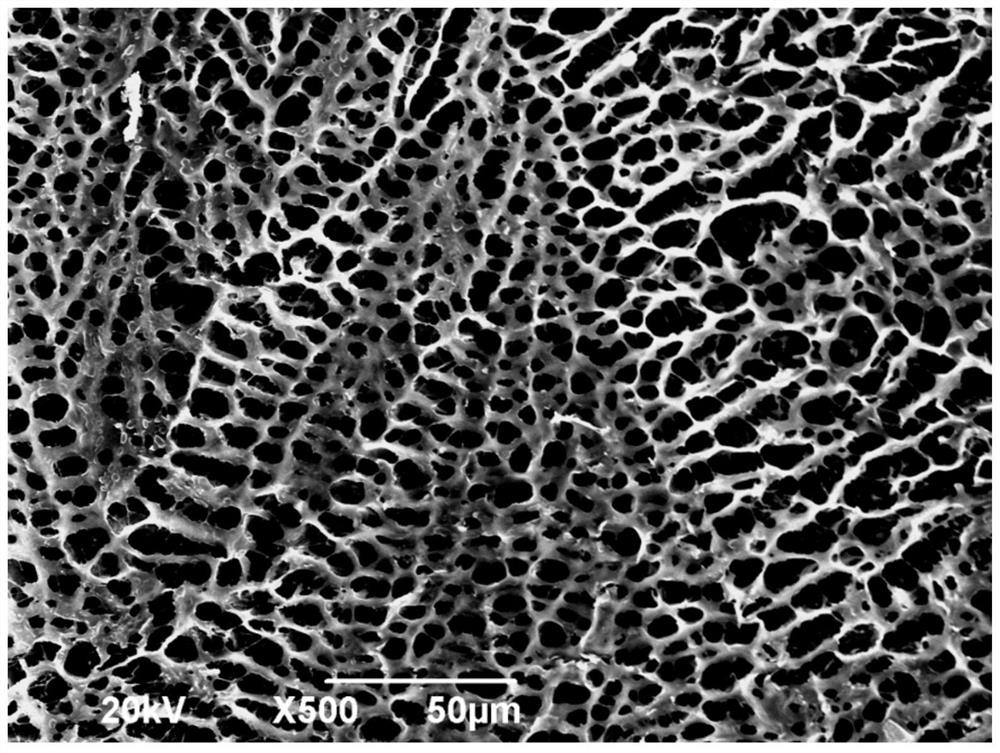

A nano-silicon and cross-linking agent technology, applied in the field of polymer material synthesis, can solve the problems of low hydrogel strength, slow response speed, single structure, etc., and achieve the effect of improving mechanical properties and temperature response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

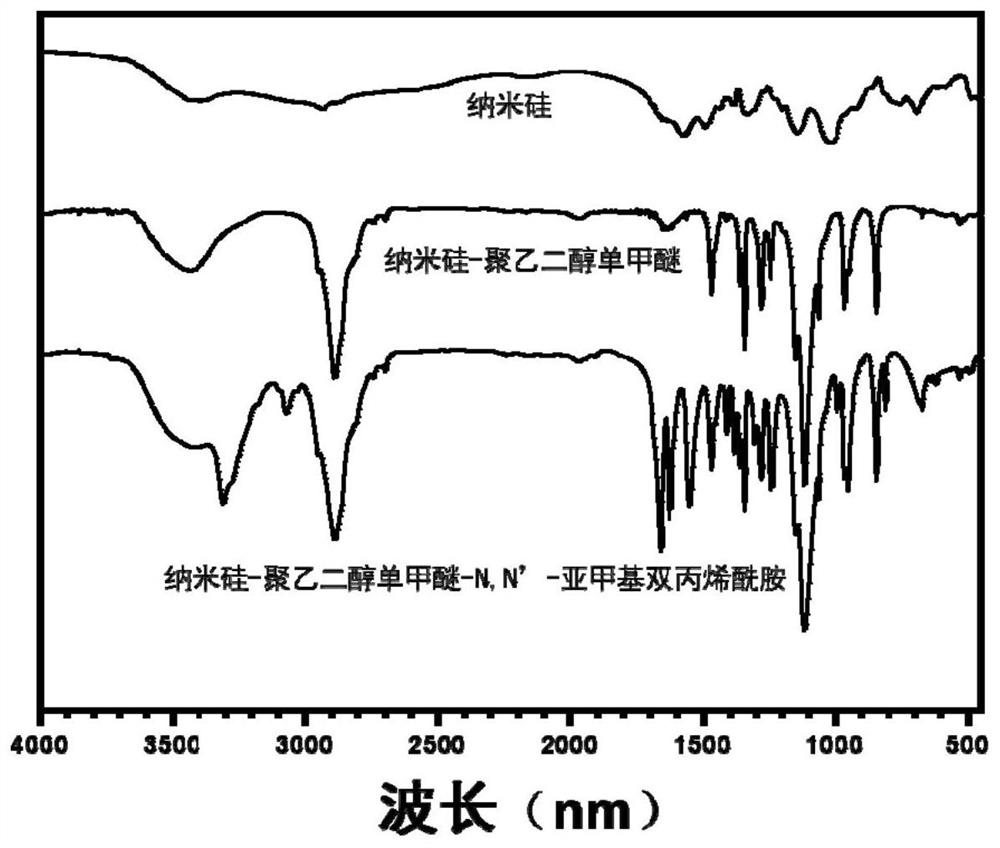

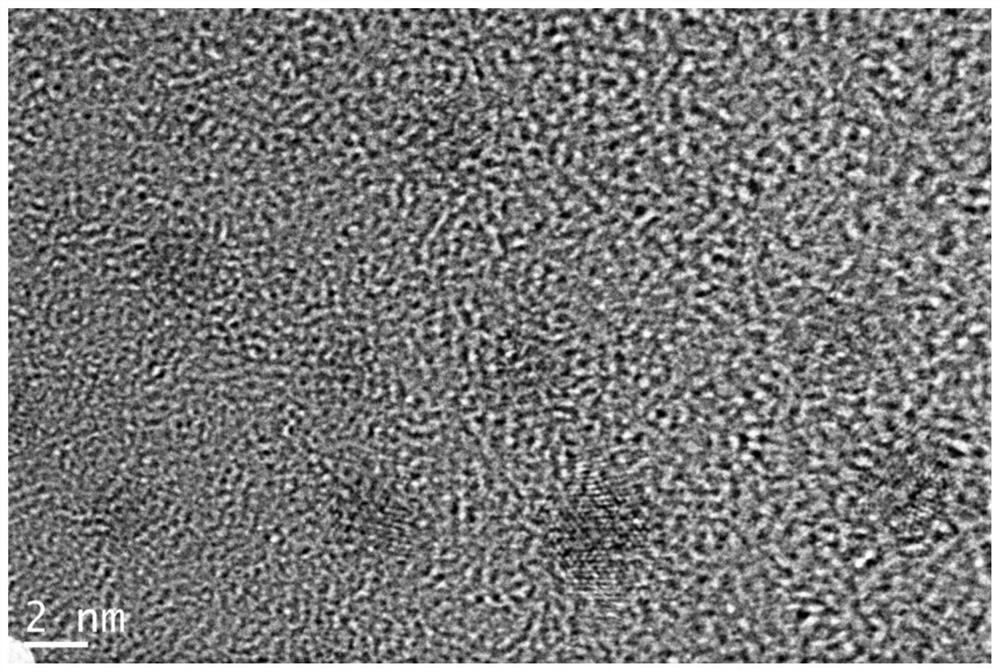

[0047] A preparation method of nano silicon crosslinking agent, comprising the following steps:

[0048] (1) Take 20 grams of polyethylene glycol monomethyl ether with a molecular weight of 2000, add 110 milliliters of toluene to azeotropically remove water for 2.5 hours, cool to room temperature, add 0.45 grams of sodium hydride, stir at room temperature for 4 hours, add 4 milliliters of epoxy Chloropropane, continue to stir for 12 hours, obtain the crude product by adding n-hexane to precipitate, and dissolve the crude product in dichloromethane, add water to extract three times, add anhydrous sodium sulfate to dry, suction filter, concentrate the solvent, and continue to contain the crude product Use n-hexane precipitation three times to obtain polyethylene glycol monomethyl ether whose end group is epoxy;

[0049] (2) Take 80 ml of ultrapure water and add it to the flask, add 20 ml of KH540 dropwise under vigorous stirring, and after ten minutes, add 25 ml of 0.1M sodium asc...

Embodiment 2

[0053] A kind of preparation method of nano-silicon crosslinking agent, other are with embodiment 1, just use 10 grams of molecular weight in step (1) and be the polyethylene glycol monomethyl ether of 1000.

[0054] The double bond concentration of the nano-silicon crosslinking agent prepared in this embodiment is 1643 g / mol, and the double bond concentration is obtained by bromine titration.

Embodiment 3

[0056] A kind of preparation method of nano-silicon crosslinking agent, other are with embodiment 1, just use 5 grams of molecular weights in step (1) and be the polyethylene glycol monomethyl ether of 500.

[0057] The double bond concentration of the nano-silicon crosslinking agent prepared in this embodiment is 1183 g / mol, and the double bond concentration is obtained by bromine titration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com