Double-wall-layer intumescent fireproof flame retardant co-microcapsule and preparation method thereof

An intumescent, flame retardant technology, used in the field of flame retardants, can solve the problems of foaming and falling off, easy wrinkling, poor compatibility, etc., and achieve the effects of improving coating efficiency, enhancing hydrophobicity, and improving water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

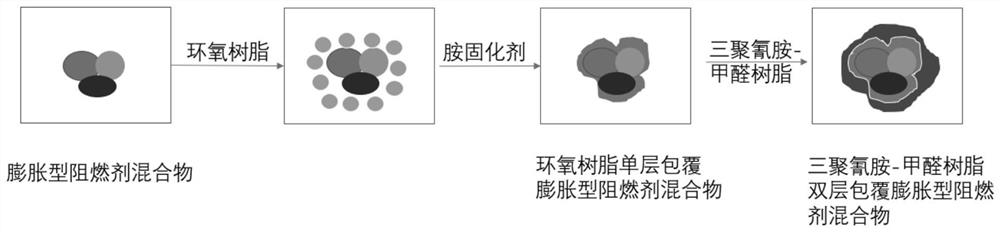

[0030] A kind of preparation method of double-walled intumescent fire retardant co-microcapsules, such as figure 1 As shown, the specific steps are as follows:

[0031] Step S1, the mixture of epoxy resin-coated intumescent fire retardant acid source, carbon source and gas source:

[0032] Mix 10-30g of epoxy resin and 120-300g of solvent evenly at 100-300rpm stirring condition, then add 90-110g of the mixture of intumescent fire retardant acid source, carbon source and gas source, and in 40- Stir in a constant temperature water bath at 50°C for 30-60min at a constant temperature at a speed of 1000-5000rpm, then add 1-8g of amine curing agent, react for 2-4h, filter with suction, and dry at 50°C for 36-48h to obtain EP-Mix ;

[0033] Step S2, melamine-formaldehyde resin coating epoxy resin:

[0034] Add 10-20g of melamine, 10-25g of formaldehyde solution (37%) and 80-120g of water into a 500ml four-neck flask, stir thoroughly, adjust the pH of the above solution to 7.5-9 wi...

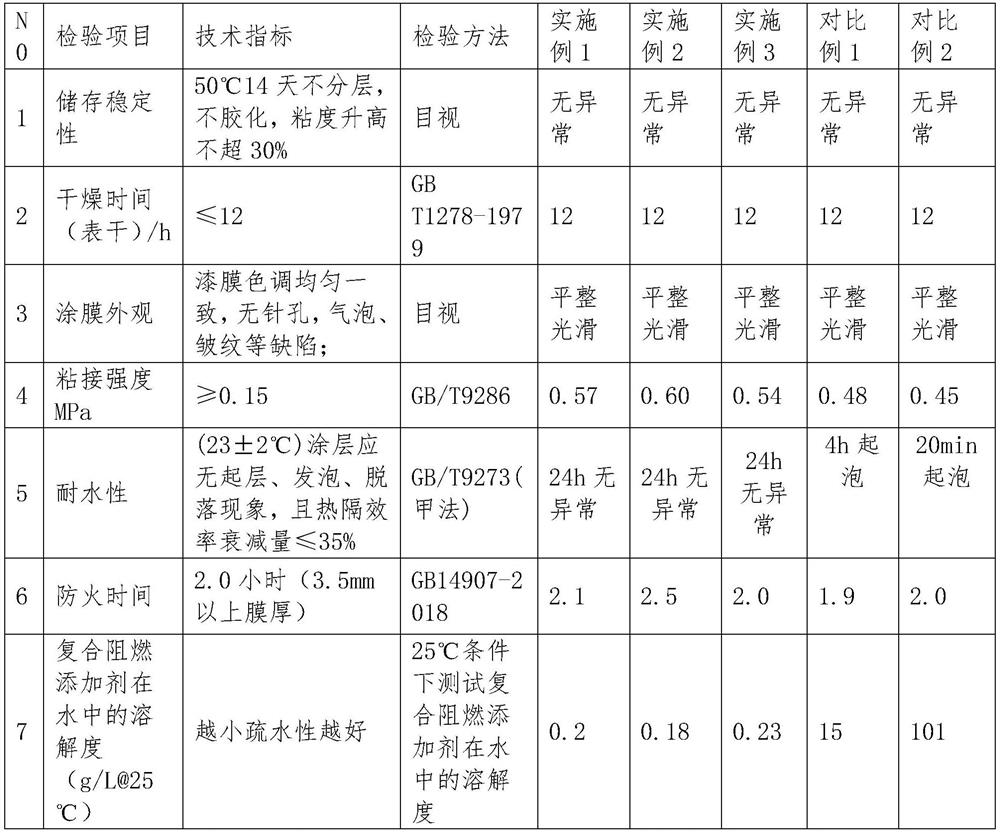

Embodiment 1

[0041]Mixture of epoxy resin-coated intumescent fire retardant acid source, carbon source and gas source: Mix 15g epoxy resin and 150g acetone at 150rpm under stirring condition, then add 100g of APP, PER and MEL mixture, and mix at 50 ℃ Stir in a constant temperature water bath for 30min at a constant temperature at a stirring rate of 2000rpm, then add 2.2g of triethylenetetramine curing agent, raise the temperature to 70°C, react for 2h, filter with suction, and dry at 50°C for 36h to obtain EP-Mix.

[0042] Melamine-formaldehyde resin coated epoxy resin:

[0043] 13g of melamine, 10g of formaldehyde solution (37%) and 77g of water were added to a 250ml four-neck flask, fully stirred, and the pH of the above solution was adjusted to 7.5 with saturated aqueous sodium carbonate solution, then the temperature was raised to 80°C while stirring, and the reaction was carried out for 45min. That is, the MF resin prepolymer is obtained.

[0044] Under stirring conditions, add 20g o...

Embodiment 2

[0046] Epoxy resin-coated intumescent fire retardant mixture of acid source, carbon source and gas source:

[0047] Mix 10g of epoxy resin and 120g of acetone at 300rpm and mix evenly, then add 100g of APP, PER and MEL mixture, and stir in a constant temperature water bath at 40°C for 60min at a speed of 2000rpm, then add 1.5g of triethylenetetramine curing agent , reacted for 4h, filtered with suction, and dried at 50°C for 48h to obtain EP-Mix.

[0048] Melamine-formaldehyde resin coated epoxy resin:

[0049] Add 20 g of melamine, 25 g of formaldehyde solution (37%) and 120 g of water into a 500 ml four-neck flask, stir thoroughly, adjust the pH of the above solution to 8 with saturated aqueous sodium carbonate solution, then heat up to 70 ° C while stirring, and react for 45 min. That is, the MF resin prepolymer is obtained.

[0050] Under stirring conditions, add 100g of the above-mentioned MF resin prepolymer solution, then add 40g of absolute ethanol and 100g of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com