Large-scale manufacturing method of diagnostic magnetic beads and biological application thereof

A manufacturing method and large-scale technology, applied in biochemical equipment and methods, microbiological measurement/inspection, DNA preparation, etc., can solve problems such as difficult to achieve large-scale manufacturing and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

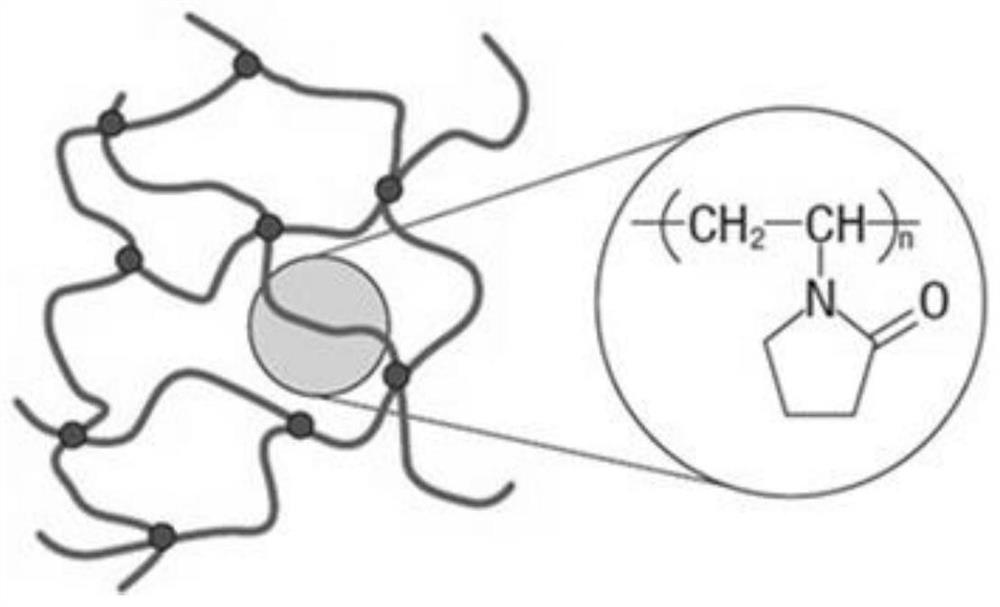

[0123] Example 1: Preparation method of diagnostic magnetic beads M1

[0124] 1) preparing magnetically cross-linked povidone particles;

[0125] 2) modifying the porous inorganic silica layer with the magnetic cross-linked povidone described in step 1 to prepare silicon-based magnetic cross-linked povidone particles;

[0126] 3) modifying the silicone layer on the silicon-based magnetic cross-linked povidone particles described in step 2 to prepare double-layer silicon-based magnetic cross-linked povidone particles.

[0127] Wherein, the specific synthesis steps of the cross-linked povidone particles in the step 1) include:

[0128] 1-1) 100 parts by mass of crospovidone particles with a particle size of 5-10 μm, crospovidone particles, 400 parts by mass of glycerin, 600 parts by mass of ethanol and 1000 parts by mass of water were mixed and mechanically stirred for 1 hour to disperse;

[0129] 1-2) After feeding nitrogen for 1 hour, add 100 parts by mass of ferrous ammoni...

Embodiment 2

[0138] Embodiment 2: the preparation method of diagnostic magnetic beads M2

[0139] 1) preparing magnetically cross-linked povidone particles;

[0140] 2) modifying the porous inorganic silica layer with the magnetic cross-linked povidone described in step 1 to prepare silicon-based magnetic cross-linked povidone particles;

[0141] 3) modifying the silicone layer on the silicon-based magnetic cross-linked povidone particles described in step 2 to prepare double-layer silicon-based magnetic cross-linked povidone particles.

[0142] Wherein, the specific synthesis steps of the cross-linked povidone particles in the step 1) include:

[0143] 1-1) 150 parts by mass of crospovidone particles with a particle size of 10-20 μm, 200 parts by mass of glycerin, 500 parts by mass of ethanol and 800 parts by mass of water are mixed and mechanically stirred for 1 hour until dispersed;

[0144] 1-2) After feeding nitrogen for 1 hour, add 150 parts by mass of ferrous ammonium sulfate, 280...

Embodiment 3

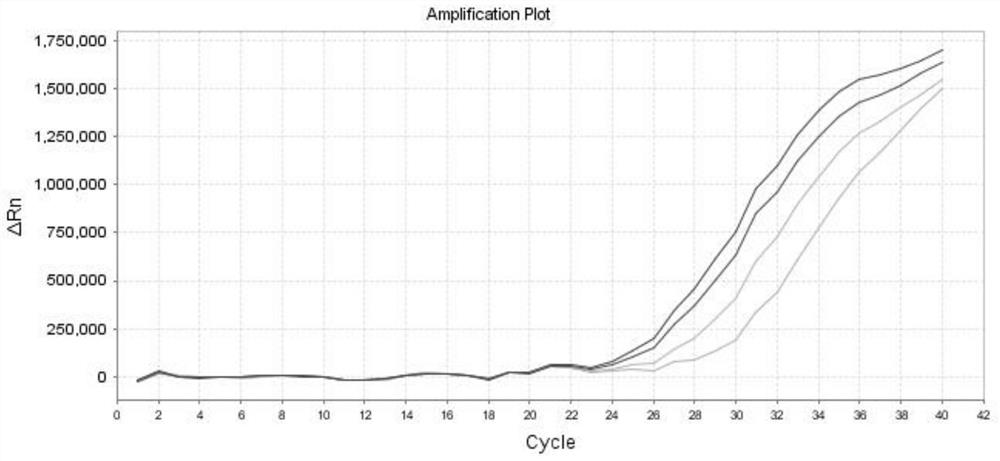

[0153] Embodiment 3: Magnetic leakage test of diagnostic magnetic beads M1, M2 and commercialized magnetic beads

[0154] The diagnostic magnetic beads M1, M2 provided in Example 1 and the MagneSil magnetic beads of Promega Company (product number MD1441), the Dynabeads MyOne of Thermo Company TM Silane (Product No. 37002D) was diluted with sterile water to 10mg / mL, and 1mL of the above-mentioned diluted magnetic bead suspension was taken. After repeated washing with deionized water for 3 times, 1mL of 0.5M HCl was added and reacted at room temperature for 1 hour at 1500rpm. The supernatant was absorbed by magnetic separation and the content of iron ions in the supernatant was detected by atomic absorption. Table 1 shows that the diagnostic magnetic beads M1 and M2 have low magnetic leakage, while the commercial magnetic beads MagneSil and MyOne TM The magnetic leakage of Silane is very obvious.

[0155] Table 1: Magnetic leakage test of different magnetic beads

[0156] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com