Processing method for electroplating pretreatment

A technology of pre-treatment and treatment method for electroplating, which is applied in the field of electroplating and can solve the problems that nickel powder is not easy to coat the surface of metal parts, and the efficiency of electroplating treatment is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

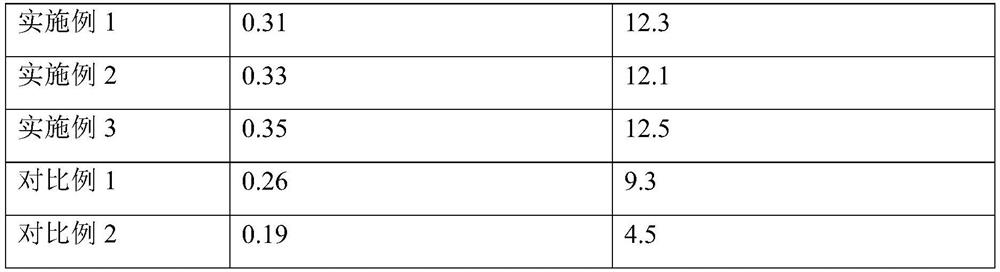

Embodiment 1

[0029] A kind of processing method of electroplating pretreatment of the present embodiment, comprises the following steps:

[0030] Step 1, the preparation of metamorphic loading agent:

[0031] S1, activation of the support body: 55 parts of bentonite powder are first irradiated with protons for 10 minutes, the irradiation power is 150W, after the irradiation is completed, continue to activate in the plasma equipment, and the activation is completed;

[0032] S2, the surface wetting of the carrier: add the activated bentonite powder to 80 parts of deionized water, then add 5 parts of sodium lauryl sulfate, stir at a constant speed of 350r / min for 30min, and then add 10 parts Parts of sodium carbonate solution, continue to stir for 15min, get final product;

[0033] S3, preparation of modified loading agent: send the bentonite powder treated in S2 and the modified wollastonite powder with a total amount of 30% into the reaction kettle, then add an active medium agent with a ...

Embodiment 2

[0045] A kind of processing method of electroplating pretreatment of the present embodiment, comprises the following steps:

[0046] Step 1, the preparation of metamorphic loading agent:

[0047] S1, the activation of the support body: 65 parts of bentonite powder are first irradiated with protons for 20 minutes, the irradiation power is 250W, after the irradiation is completed, continue to activate in the plasma equipment, and the activation is completed;

[0048] S2, the surface wetting of the support body: add the activated bentonite powder to 120 parts of deionized water, then add 10 parts of sodium lauryl sulfate, first stir at a constant speed of 450r / min for 40min, then add 20 parts Parts of sodium carbonate solution, continue to stir for 25min, get final product;

[0049] S3, preparation of modified loading agent: send the bentonite powder treated in S2 and the modified wollastonite powder with a total amount of 40% into the reaction kettle, then add an active medium ag...

Embodiment 3

[0061] A kind of processing method of electroplating pretreatment of the present embodiment, comprises the following steps:

[0062] Step 1, the preparation of metamorphic loading agent:

[0063] S1, Activation of the support body: 60 parts of bentonite powder are first irradiated with protons for 15 minutes, the irradiation power is 200W, after the irradiation is completed, continue to activate in the plasma equipment, and the activation is completed;

[0064] S2, the surface wetting of the carrier: add the activated bentonite powder to 100 parts of deionized water, then add 7.5 parts of sodium lauryl sulfate, first stir at a constant speed of 400r / min for 35min, then add 15 parts Parts of sodium carbonate solution, continue to stir for 20min, get final product;

[0065] S3, preparation of modified loading agent: send the bentonite powder treated in S2 and the modified wollastonite powder with a total amount of 35% into the reaction kettle, then add an active medium agent wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com