A kind of silver molybdate nanofiber material and preparation method thereof

A nanofiber, silver molybdate technology, applied in the fields of botanical equipment and methods, fiber processing, nanotechnology, etc., can solve the problems of uneven particle size, low load, complicated operation, etc., and achieve uniform particle size and distribution. , The effect of large load and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of silver molybdate nanofiber material under dark conditions includes the following steps:

[0040] (1) Weigh 0.178g of solid peroxymolybdic acid and place it in a beaker, add 100ml of ethanol, ultrasonically and continue stirring for 3h to obtain a uniform orange-yellow peroxymolybdic acid-ethanol suspension;

[0041] (2) take by weighing silver nitrate 0.169g, dissolve it in 35ml deionized water, then add the silver nitrate solution dropwise to the peroxymolybdic acid-ethanol suspension under vigorous stirring, continue stirring for 30min, obtain the precursor solution ;

[0042] (3) Transfer the precursor solution into the flask, continue the oil bath at 85°C and stir vigorously for 24h;

[0043] (4) After the reaction, the system was cooled naturally, the product was centrifuged, washed three times with ethanol and twice with acetone, and then vacuum-dried at 45° C. for 24 hours to obtain the product.

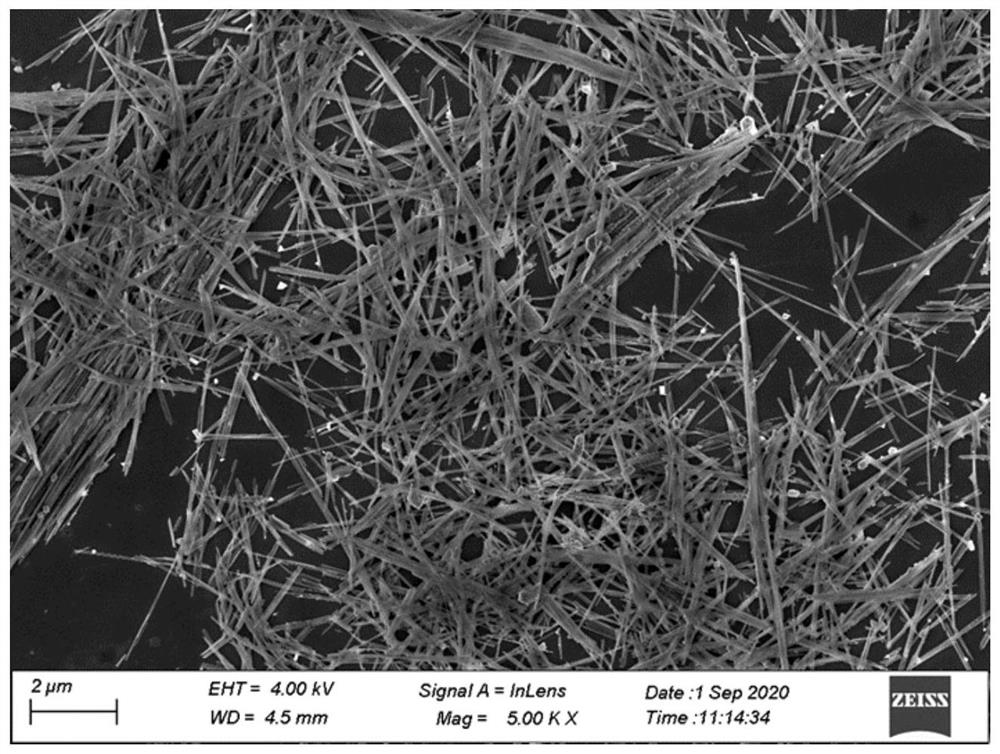

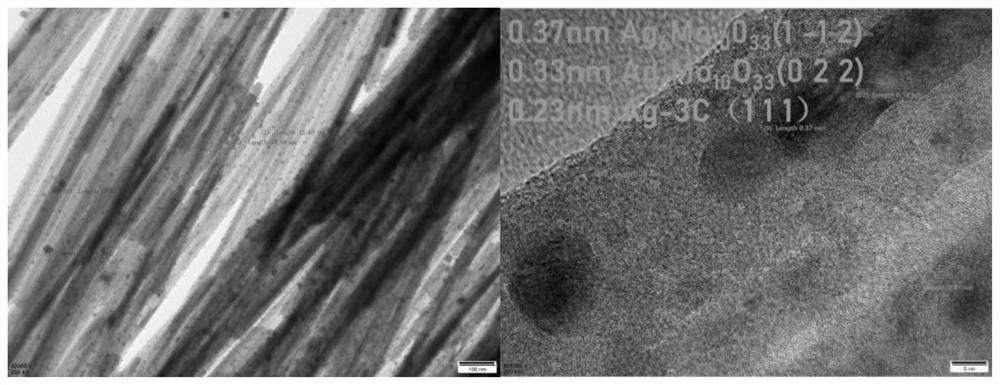

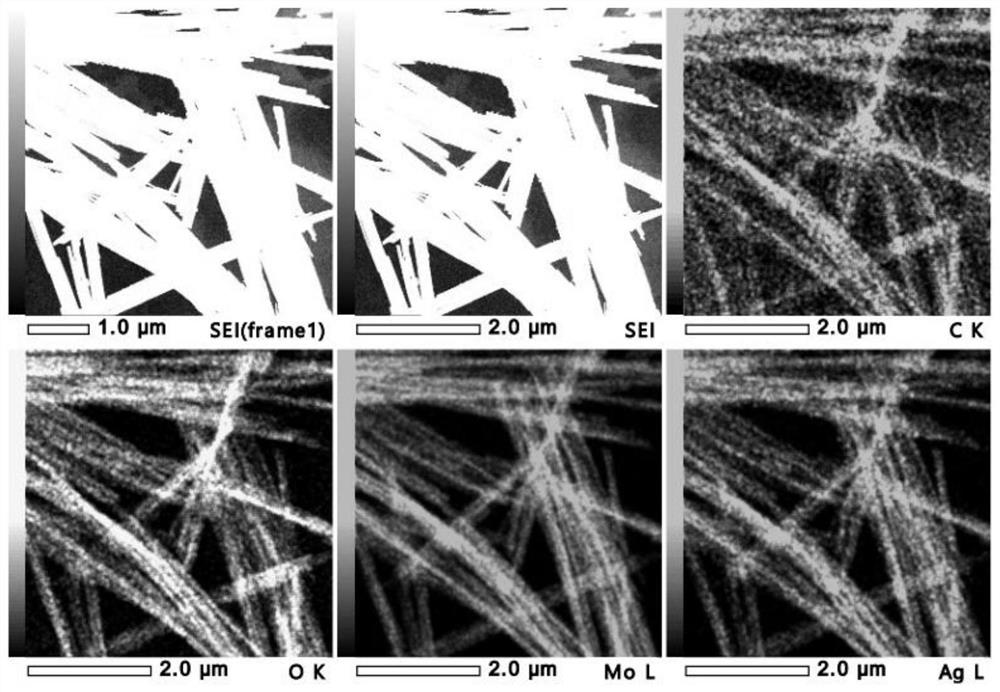

[0044] combine Figures 1 to 3 and Figure ...

Embodiment 2

[0046] The preparation method of the silver molybdate nanofiber material is the same as that in Example 1, except that the n-butanol used in step (1) is changed to ethanol.

[0047] combine Figures 4 to 6 and Figure 11 It can be seen that the main component of the material prepared in this example is Ag 2 MoO 4 , contains a small amount of Ag 6 Mo 10 O 33 , Ag 2 Mo 2 O 7 The silver molybdate nanofiber material is provided with uniformly distributed nano-silver particles on the surface of the material, the length of the fiber is about 5 μm, the width is between 50-100 nm, and the particle size of the nano-silver particle is 5-25 nm.

Embodiment 3

[0049] The preparation method of the material is the same as that in Example 1, except that 35 ml of deionized water used in step (2) is changed to 45 ml of deionized water.

[0050] combine Figure 7 and Figure 11 It can be seen that the main component of the silver molybdate nanomaterial prepared in this example is Ag 6 Mo 10 O 33 , and contains a small amount of Ag 2 MoO 4 , Ag 2 Mo 4 O 13 The length of the nanofibers is about 20 μm and the width is less than 100 nm. The scanning electron microscope image shows that there are a lot of large-sized bulk products in the obtained product, and the surface of the material is relatively smooth and does not have nano-silver particles.

[0051] The reason for this result may be because: with the increase of the amount of deionized water in the reaction system, the dissolution rate of the reaction raw materials is accelerated, and the concentration of the raw materials in the reaction system increases, which affects the anis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com