Viscose sodium sulfate waste liquid regeneration recycling process

A technology of sodium sulfate waste liquid and viscose fiber, which is applied in the fields of fiber chemical characteristics, sustainable manufacturing/processing, textile/flexible product manufacturing, etc. problem, to achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

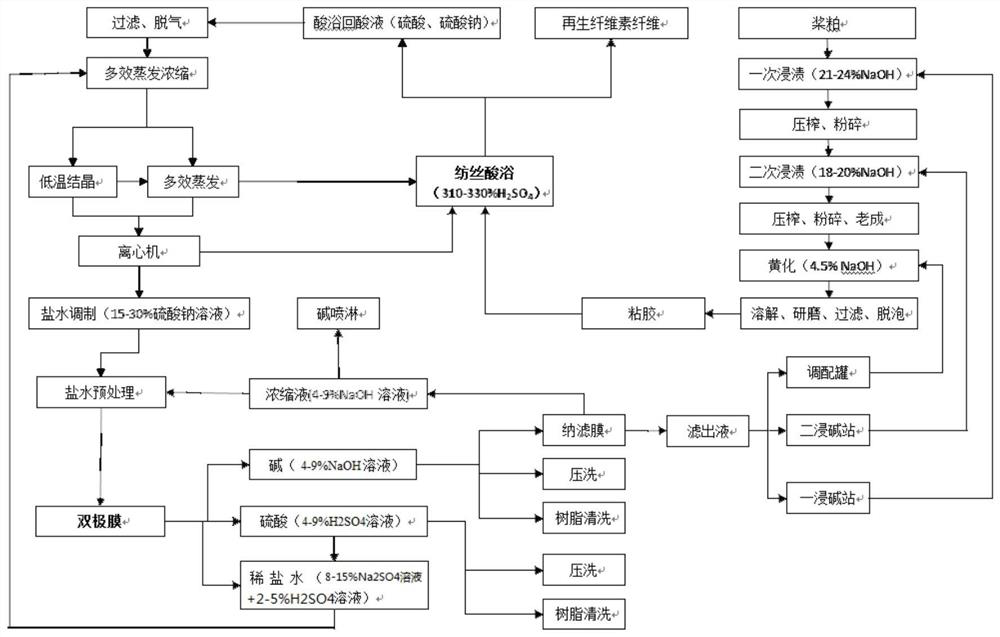

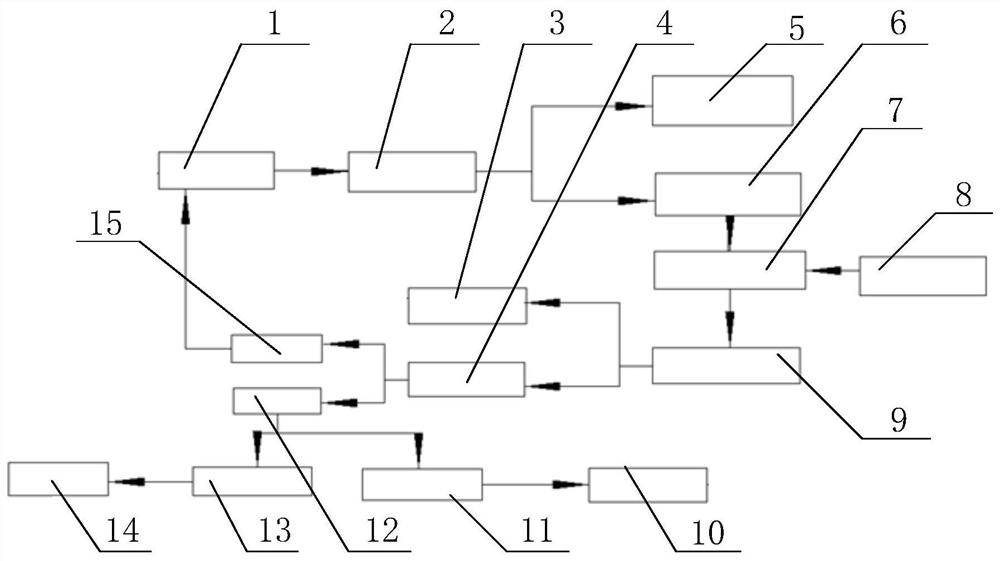

[0077] Such as figure 1 Shown, a kind of viscose fiber sodium sulphate waste liquor recycling process comprises the steps:

[0078] Step 1: Preparation of solid sodium sulfate

[0079] Spinning acid bath produces acid bath acid, which includes sulfuric acid and sodium sulfate, which is filtered and degassed, and then enters the multi-effect evaporation concentration system for evaporation and concentration, crystallization and centrifugation to obtain solid sodium sulfate, multi-effect evaporation and centrifugation. Sulfuric acid is used in the spinning acid bath process;

[0080] Step 2: Sodium sulfate brine preparation and impurity removal

[0081] Add demineralized water and solid sodium sulfate into the preparation container at the same time and stir to prepare a sodium sulfate solution with a concentration of 15-30%, and pass it into the pretreatment system, and remove it from the sodium sulfate solution after filtration by the pretreatment system and resin adsorption....

Embodiment 2

[0096] The difference between this embodiment and Example 1 is that resin recovery treatment is required after the resin for removing impurities of sodium sulfate is adsorbed and saturated, and the recovery treatment steps of the resin include: replacing the saturated resin with brine, high-pressure air Rinsing, pickling, water washing and alkali washing, the acid used in the pickling includes the sulfuric acid solution obtained after the bipolar membrane treatment system, and the alkali used in the alkali washing includes the lye obtained after the bipolar membrane treatment system.

[0097] The resin recovery process of the present invention adopts brine replacement flushing, high-pressure air flushing, and pickling to process the saturated resin. First, the brine replacement flushing can dilute the concentration of sodium sulfate solution in the resin tower, preventing sodium sulfate crystals from adhering to the resin surface. , affect cleaning, and at the same time remove ...

Embodiment 3

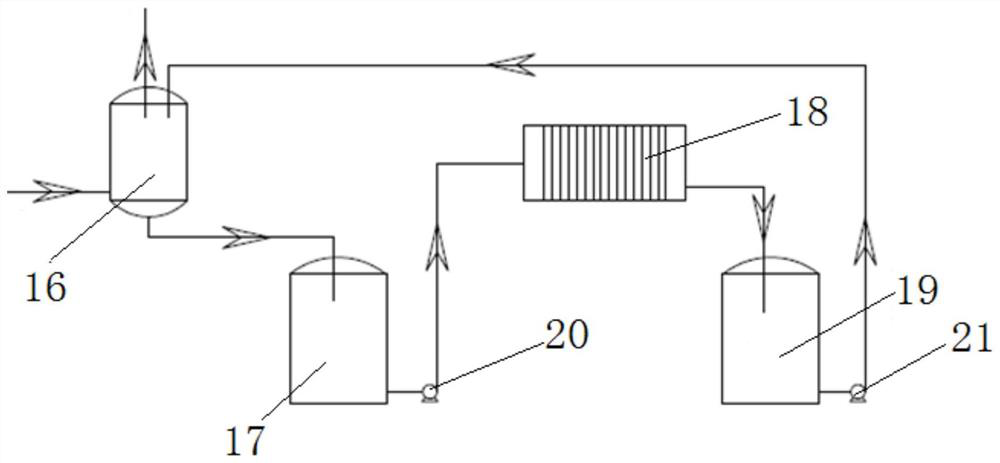

[0105] The lye that is filtered out after the lye is processed by the nanofiltration membrane is used in the immersion of the glue making process, which is called the lye dipping, and also needs to be treated with impurity removal. The liquid is filtered, and a layer of cellulose layer is pre-coated on the filter element of the VCF filter. The cellulose layer adopts plant cellulose with a size of 40-60 μm, and the thickness of the cellulose layer is 10 μm.

[0106] The cleaning method of dipping lye of the present invention can greatly improve the filtration precision by pre-coating a layer of cellulose layer on the filter core of the VCF filter, and can effectively filter large particles in the lye, and at the same time, the filter residue is easy to disassemble and rinse without manual labor. Operation, reduce labor intensity, improve efficiency, less washing water consumption, filter residue is dry cake, which can reduce the discharge of waste lye, which is economical and en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com