Antibacterial anti-ultraviolet polyethylene non-woven fabric and preparation method thereof

An anti-ultraviolet and polyethylene technology, applied in textiles and papermaking, anti-staining/anti-fouling fibers, biochemical fiber treatment, etc. Mechanical properties, resistance to antibacterial resistance, effect of improving antibacterial and anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

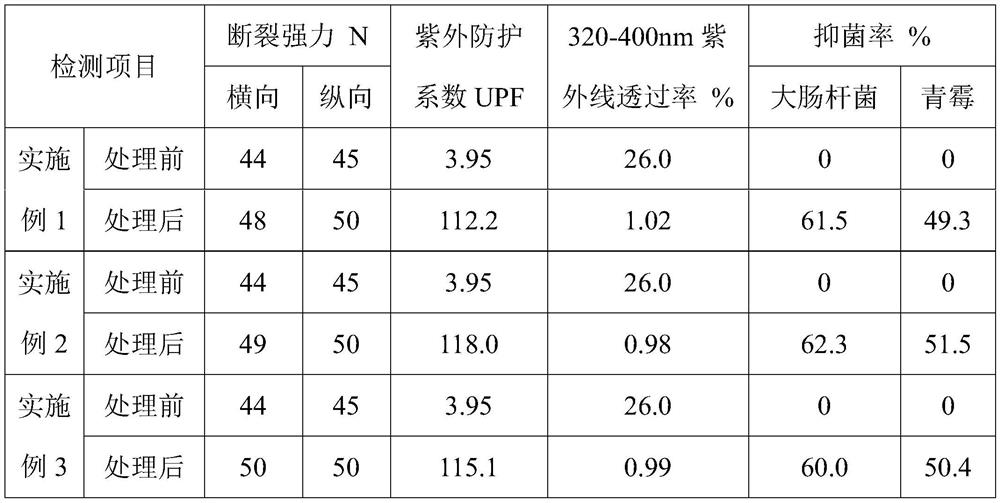

Embodiment 1

[0026] An antibacterial and anti-ultraviolet polyethylene non-woven fabric, the surface of the polyethylene non-woven fabric is sequentially adhered with an anti-fouling layer and an anti-bacterial and anti-ultraviolet layer, wherein the raw materials of the anti-fouling layer are dopamine and polyvinylpyrrolidone, and the anti-bacterial and anti-ultraviolet layer It is modified silicon dioxide; the weight ratio of dopamine and polyvinylpyrrolidone is 1:2;

[0027] During the preparation of modified silica, add 4.5g of porous silica with a particle size of 200-300nm and a pore size of ≤4nm into 500ml of water for ultrasonic dispersion for 30min, then add 30ml of silver nitrate aqueous solution with a concentration of 0.1g / ml and mix well , add 1.35g formaldehyde and mix well, stir and adsorb at room temperature for 24h, filter, and wash the filter cake with water to obtain the intermediate material; the 6.0g intermediate material is added with a mass fraction of γ-aminopropyltr...

Embodiment 2

[0032] An antibacterial and anti-ultraviolet polyethylene non-woven fabric, the surface of the polyethylene non-woven fabric is sequentially adhered with an anti-fouling layer and an anti-bacterial and anti-ultraviolet layer, wherein the raw materials of the anti-fouling layer are dopamine and polyvinylpyrrolidone, and the anti-bacterial and anti-ultraviolet layer It is modified silicon dioxide; the weight ratio of dopamine and polyvinylpyrrolidone is 1:3;

[0033] During the preparation of modified silica, 3 g of porous silica with a particle size of 200-300 nm and a pore size of ≤4 nm was added to 500 ml of water for ultrasonic dispersion for 30 minutes, and then 30 ml of silver nitrate aqueous solution with a concentration of 0.1 g / ml was added and mixed evenly. Add 1.5g formaldehyde and mix well, stir and adsorb at room temperature for 18h, filter, wash the filter cake with water to obtain the intermediate material; add 4.5g of the intermediate material to the ethanol aqueo...

Embodiment 3

[0038] An antibacterial and anti-ultraviolet polyethylene non-woven fabric, the surface of the polyethylene non-woven fabric is sequentially adhered with an anti-fouling layer and an anti-bacterial and anti-ultraviolet layer, wherein the raw materials of the anti-fouling layer are dopamine and polyvinylpyrrolidone, and the anti-bacterial and anti-ultraviolet layer It is modified silicon dioxide; the weight ratio of dopamine and polyvinylpyrrolidone is 1:2.5;

[0039] During the preparation of modified silica, 4 g of porous silica with a particle size of 200-300 nm and a pore size of ≤4 nm was added to 500 ml of water for ultrasonic dispersion for 30 min, and then 30 ml of silver nitrate aqueous solution with a concentration of 0.1 g / ml was added and mixed evenly. Add 1.4g formaldehyde and mix well, stir and adsorb at room temperature for 20h, filter, wash the filter cake with water to obtain the intermediate material; 5g of the intermediate material is added to the ethanol aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com