A physical separation and recovery method for positive and negative electrode materials of waste ternary lithium batteries

A technology of ternary lithium battery and positive and negative electrodes is applied in the field of physical sorting and recycling of positive and negative electrode materials of waste ternary lithium batteries, which can solve the problems of high cost of chemical separation and disposal, unrecovered graphite materials, etc., and achieve the elimination of adhesion. , Increase the difference of floatability and the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

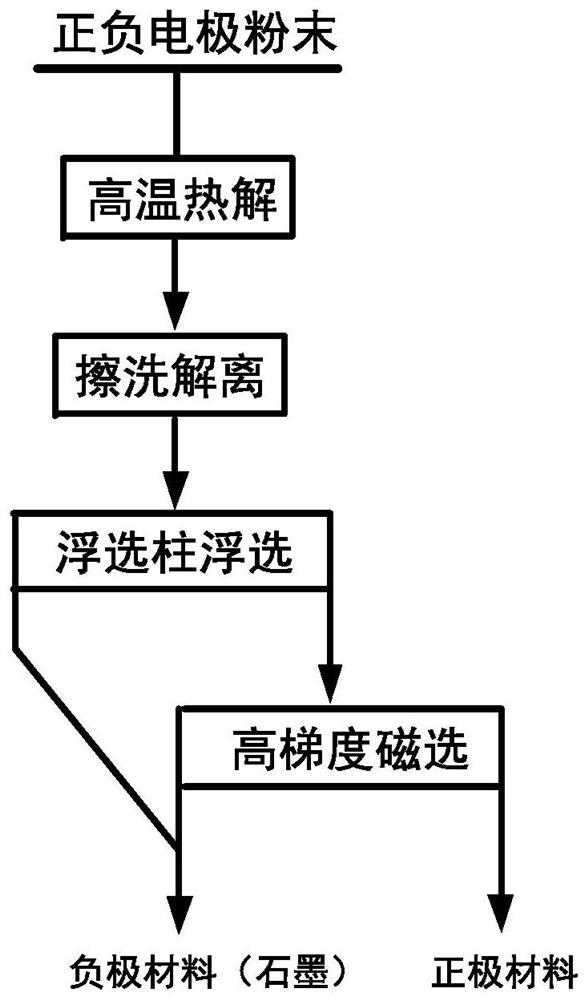

[0027] The physical sorting and recycling method of the positive and negative electrode materials of the waste ternary lithium battery of the present embodiment, the process flow chart is shown in figure 1 shown. The positive and negative electrode materials of a ternary lithium battery in Foshan, Guangdong were sorted according to the following steps:

[0028] (1) Put the mixed powder of the positive and negative electrodes of the waste ternary lithium battery in a pyrolysis furnace, heat it for 2.0 h at a temperature of 350 °C and an inert atmosphere, and condense and collect the electrode powder after pyrolysis.

[0029] (2) The electrode powder after pyrolysis in step (1) is mixed with water to prepare a slurry with a mass percentage concentration of 68% and placed in a scrubbing machine, and the scrubbing time is 18 minutes.

[0030] (3) Introducing the scrubbed slurry in step (2) into the mixing tank, adding water to prepare a slurry with a mass percentage concentration...

Embodiment 2

[0034] The physical sorting and recycling method of the positive and negative electrode materials of the waste ternary lithium battery of the present embodiment, the process flow chart is shown in figure 1 shown. The positive and negative electrode materials of a ternary lithium battery in Shenzhen, Guangdong were sorted according to the following steps:

[0035] (1) Put the mixed powder of the positive and negative electrodes of the waste ternary lithium battery in a pyrolysis furnace, heat it for 1.5 hours at a temperature of 400 °C under an inert atmosphere, and condense and collect the electrode powder after pyrolysis.

[0036] (2) adding water to the pyrolyzed electrode powder to prepare a slurry with a mass percentage concentration of 70% and placing it in a scrubbing machine for a scrubbing time of 20 minutes.

[0037] (3) introducing the scrubbed slurry into the mixing tank, adding water to prepare a slurry with a mass percentage concentration of 10%, and adding sodiu...

Embodiment 3

[0041] The physical sorting and recycling method of the positive and negative electrode materials of the waste ternary lithium battery of the present embodiment, the process flow chart is shown in figure 1 shown. The positive and negative electrode materials of a ternary lithium battery in Jiangmen, Guangdong were sorted according to the following steps:

[0042] (1) Put the mixed powder of the positive and negative electrodes of the waste ternary lithium battery in a pyrolysis furnace, heat it for 2.0 h at a temperature of 450 ℃ and an inert atmosphere, and condense and collect the electrode powder after pyrolysis.

[0043] (2) adding water to the pyrolyzed electrode powder to prepare a slurry with a mass percentage concentration of 65% and placing it in a scrubbing machine, and the scrubbing time is 15 minutes.

[0044] (3) Introduce the scrubbed slurry into the mixing tank, add water to prepare a slurry with a mass percentage concentration of 15%, and add sodium carbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com