A kind of method and system for processing aromatic-rich distillate oil

A technology for distillate oil and aromatics, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of short operation period, low hydrogen content of hydrogenated residue, low yield of propylene, etc., and achieve good hydrogenation Effects of Processing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

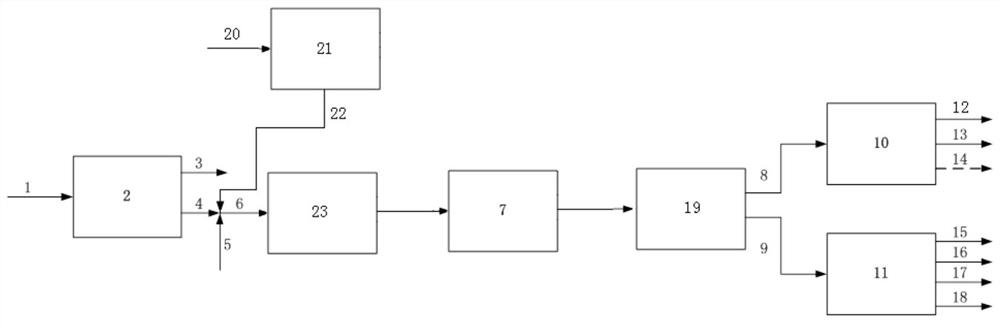

Method used

Image

Examples

Embodiment A

[0120] Preparation of rich ore precursor material 1: Select 2000 g of RPB110 pseudo-boehmite produced by Sinopec Catalyst Co., Ltd. Changling Branch, of which 1000 g is treated at 550 ° C for 2 hours to obtain about 700 g of alumina, and about 700 g of alumina and another 1000 g of pseudo-boehmite are obtained. The boehmite was thoroughly mixed, then 40g of saffron powder and 20g of citric acid were added, and 2200g of deionized water was added, kneaded and extruded into strips, dried at 300°C for 3h to obtain about 1730g of carrier, and 2100mL of Mo and Ni were added. The solution is saturated and impregnated, and the Mo content in the solution is the same as MoO 3 The mass was 5.5%, and the Ni content was 1.5% by mass of NiO. It was immersed for half an hour, and then treated at 180° C. for 4 hours to obtain a rich ore precursor material 1. The properties are shown in Table 6.

[0121] Preparation of rich ore precursor material 2: Select 2000 g of RPB110 pseudo-boehmite prod...

Embodiment 1

[0124] The aromatic-rich distillate used in this example is LCO, which comes from the RLG unit of Shanghai Petrochemical. The LCO hydrogenation operating conditions are: the reaction temperature is 290°C, the reaction pressure is 4MPa, and the liquid hourly volume space velocity is 1h -1 , the volume ratio of hydrogen to oil is 800:1.

[0125] The properties of the LCO and the first heavy component 1 are shown in Table 1.

[0126] DOA comes from a vacuum residue, and is mixed with the first heavy component 1 in a mass ratio of 1:10. The properties of the mixed raw materials are shown in Table 2.

[0127] The mixed raw material of DOA and the first heavy component 1 is firstly in the hydrogen dissolving unit (the volume ratio of the feeding amount of hydrogen to the mixed raw material of the deoiled asphalt and the first heavy component 1 is 100, and the operating temperature of the hydrogen dissolving unit is 320 ℃, the pressure is 10 MPa) and mixed with hydrogen, and the obt...

Embodiment 2

[0131] The aromatic-rich distillate used in this example is HCO, which comes from the catalytic cracking unit of Shanghai Petrochemical. The HCO hydrogenation operating conditions are: the reaction temperature is 330°C, the reaction pressure is 6MPa, and the liquid hourly volume space velocity is 1h -1 , the volume ratio of hydrogen to oil is 800:1.

[0132] The properties of HCO and the first heavy component 2 are shown in Table 1.

[0133] DOA comes from a vacuum residue, and is mixed with the first heavy component 2 in a mass ratio of 5:10. The properties of the mixed raw materials are shown in Table 2.

[0134] The mixed raw material of DOA and the first heavy component 2 of HCO after hydrogenation is first in the hydrogen dissolving unit (the volume ratio of the amount of hydrogen fed to the mixed raw material of the deoiled asphalt and the first heavy component 2 is 100, and the dissolved hydrogen The unit operating temperature is 320 ° C, the pressure is 10 MPa), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com