Preparation method and use method of Dy monatomic permeate

A technology of permeates and atoms, which is applied in the field of preparation of Dy single-atom permeates, can solve the problems of powder waste, grain size, unevenness, etc., and achieve the effects of reducing hindrance, stable performance, and improving atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

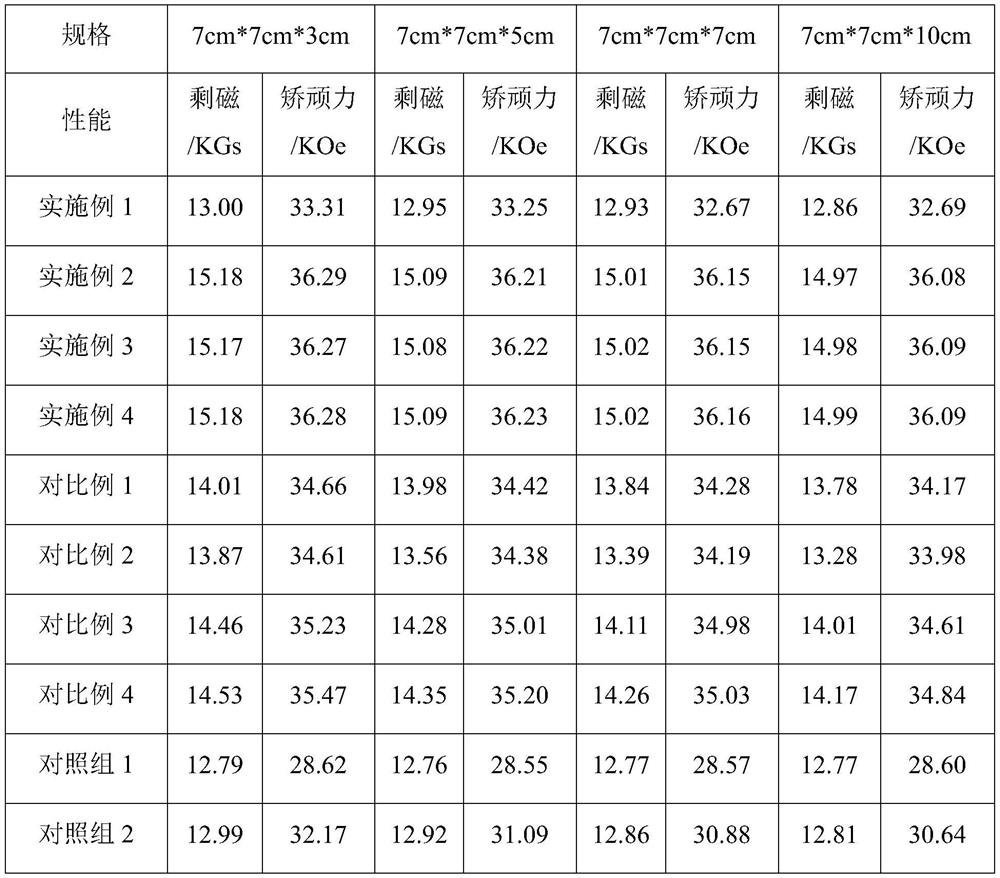

Examples

Embodiment 1

[0031]The invention provides a preparation method of Dy monoatomic permeate, which is specifically: adding ZIF-8 powder into dysprosium carbonate solution, and placing it in NH at a temperature of 900°C 3 After being kept warm for 1 hour under ambient conditions, a solid powder is obtained, which is the Dy single-atom permeate;

[0032] Wherein, dysprosium carbonate solution comprises industrial ethanol aqueous solution, bonding agent and dysprosium carbonate that weight ratio is 10:1.8:5;

[0033] The adhesive is an aqueous solution of polyvinyl propanol PVA: mix polyvinyl propanol PVA powder and water at a weight ratio of 1:10, and place it in a constant temperature water bath at 60°C, heat and stir until it is uniform and transparent, and then the adhesive is obtained. Adhesive; The volume fraction of industrial ethanol aqueous solution is 95%;

[0034] The preparation method of described dysprosium carbonate solution is: according to above-mentioned weight ratio, take ind...

Embodiment 2

[0038] The invention provides a preparation method of Dy monoatomic permeate, which is specifically: adding ZIF-8 powder into dysprosium carbonate solution, and placing it in NH at a temperature of 900°C 3 After being kept warm for 1 hour under ambient conditions, a solid powder is obtained, which is the Dy single-atom permeate;

[0039] Wherein, dysprosium carbonate solution comprises industrial ethanol aqueous solution, bonding agent and dysprosium carbonate that weight ratio is 10:1.8:5;

[0040] The adhesive is an aqueous solution of polyvinyl propanol PVA: mix polyvinyl propanol PVA powder and water at a weight ratio of 1:10, and place it in a constant temperature water bath at 60°C, heat and stir until it is uniform and transparent, and then the adhesive is obtained. Adhesive; The volume fraction of industrial ethanol aqueous solution is 95%;

[0041] The preparation method of described dysprosium carbonate solution is: according to above-mentioned weight ratio, take in...

Embodiment 3

[0049] The invention provides a preparation method of Dy monoatomic permeate, which is specifically: adding ZIF-8 powder into dysprosium carbonate solution, and placing it in NH at a temperature of 900°C 3 After being kept warm for 1 hour under ambient conditions, a solid powder is obtained, which is the Dy single-atom permeate;

[0050] Wherein, dysprosium carbonate solution comprises industrial ethanol aqueous solution, bonding agent and dysprosium carbonate that weight ratio is 10:1.8:5;

[0051] The adhesive is an aqueous solution of polyvinyl propanol PVA: mix polyvinyl propanol PVA powder and water at a weight ratio of 1:10, and place it in a constant temperature water bath at 60°C, heat and stir until it is uniform and transparent, and then the adhesive is obtained. Adhesive; The volume fraction of industrial ethanol aqueous solution is 95%;

[0052] The preparation method of described dysprosium carbonate solution is: according to above-mentioned weight ratio, take in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com