Preparation method of mixed matrix membrane material

A technology of mixed matrix membrane and mixed liquid, applied in the field of membrane materials, can solve problems such as hindering practical application and poor stability of MOF structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

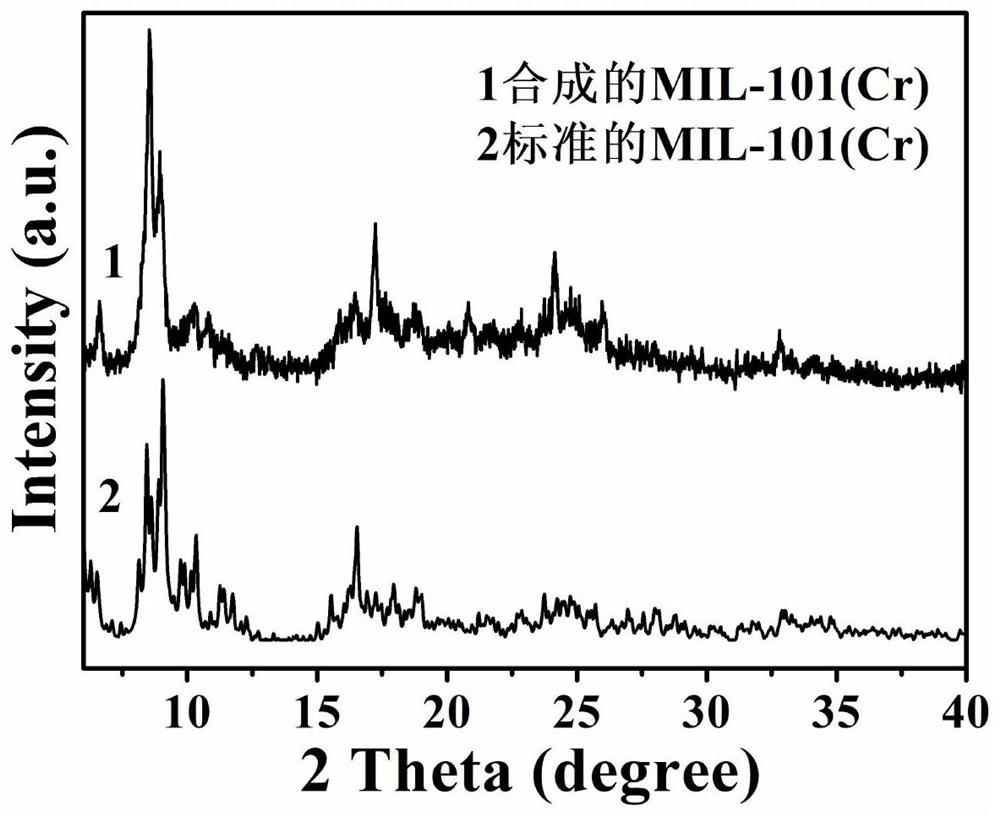

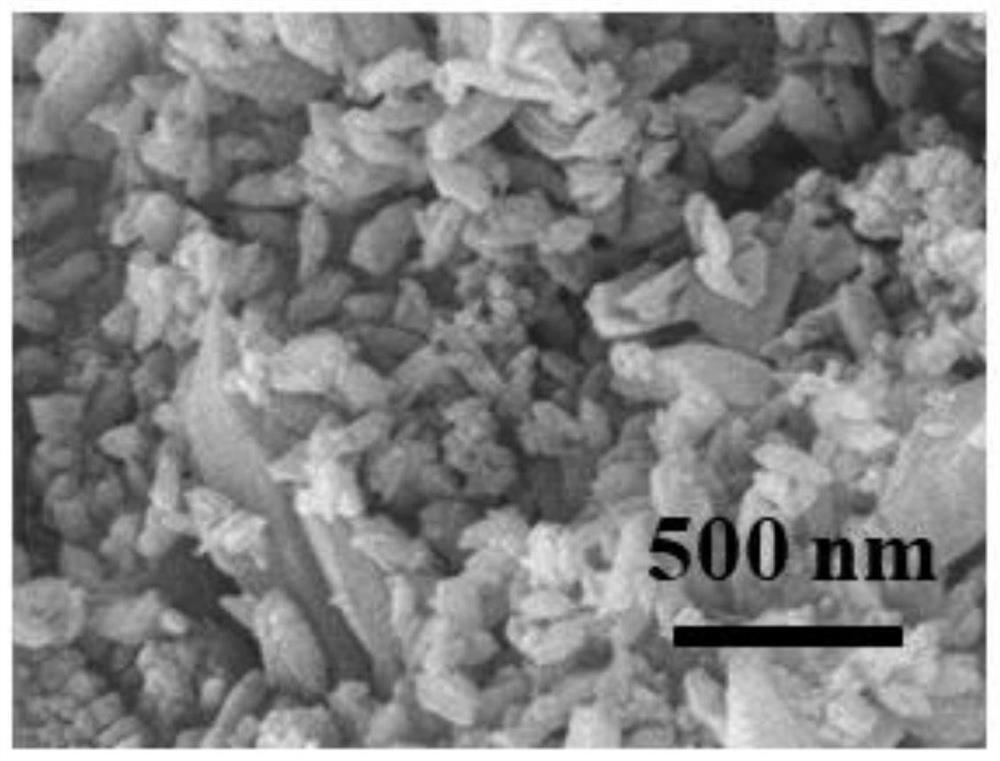

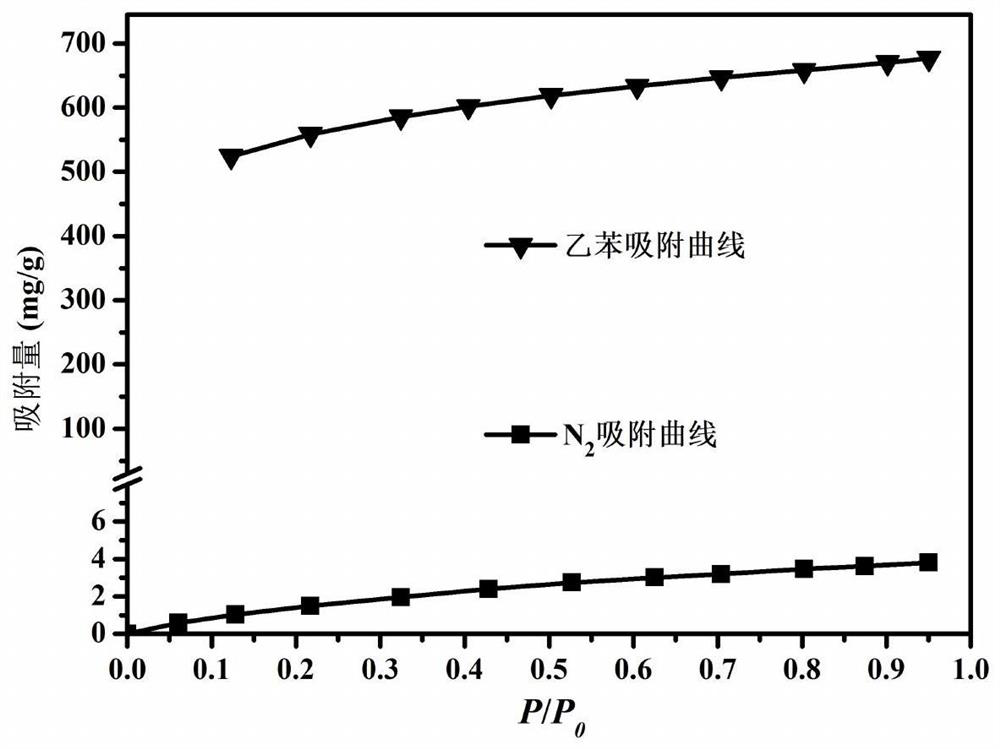

[0029] (1) Preparation process: First, accurately weigh 2.4 g of chromium nitrate nonahydrate and add it to a high-pressure reactor with a polytetrafluoroethylene liner, add 30 mL of deionized water, and then accurately weigh 0.99 g of terephthalic acid, benzene Add 2.2g of formic acid into the reaction kettle in turn, stir and sonicate for 30min until it is completely dissolved, seal it with the reaction kettle and place it in an oven at 220°C for 8h, set the program to cool down at the same time, and after 8h, use a cooling rate of 25°C / h Slowly cool the oven temperature to room temperature, collect the solid product by filtration, wash the obtained solid product repeatedly with deionized water-filter 3 times, then put the product in a 30mL glass bottle with a cover, add 20mL of anhydrous methanol, and stir for 15min Finally, tighten the cap of the bottle, let it stand for 8 hours, repeat this process 3 times, filter and collect the dark green precipitate, and place it in a b...

specific Embodiment 2

[0034](1) Preparation process: First, accurately weigh 2.4 g of chromium nitrate nonahydrate and add it to a high-pressure reactor with a polytetrafluoroethylene liner, add 30 mL of deionized water, and then accurately weigh 0.99 g of terephthalic acid, benzene Add 2.2g of formic acid into the reaction kettle in turn, stir and sonicate for 30min until it is completely dissolved, seal it with the reaction kettle and place it in an oven at 220°C for 8h, set the program to cool down at the same time, and after 8h, use a cooling rate of 25°C / h Slowly cool the oven temperature to room temperature, collect the solid product by filtration, wash the obtained solid product repeatedly with deionized water-filter 3 times, then put the product in a 30mL glass bottle with a cover, add 20mL of anhydrous methanol, and stir for 15min Finally, tighten the cap of the bottle, let it stand for 8 hours, repeat this process 3 times, collect the dark green precipitate by filtration, and dry it in a b...

specific Embodiment 3

[0039] (1) Preparation process: First, accurately weigh 2.4 g of chromium nitrate nonahydrate and add it to a high-pressure reactor with a polytetrafluoroethylene liner, add 30 mL of deionized water, and then accurately weigh 0.99 g of terephthalic acid, benzene Add 2.2g of formic acid into the reaction kettle in turn, stir and sonicate for 30min until it is completely dissolved, seal it with the reaction kettle and place it in an oven at 220°C for 8h, set the program to cool down at the same time, and after 8h, use a cooling rate of 25°C / h Slowly cool the oven temperature to room temperature, collect the solid product by filtration, wash the obtained solid product repeatedly with deionized water-filter 3 times, then put the product in a 30mL glass bottle with a cover, add 20mL of anhydrous methanol, and stir for 15min Finally, tighten the cap of the bottle, let it stand for 8 hours, repeat this process 3 times, collect the dark green precipitate by filtration, and dry it in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com