Device and method for preparing furan by furfural gas-phase decarbonylation

A furfural, gas-phase technology, applied in the direction of organic chemistry, can solve the problems of uneven local reaction of the reactor, inability to supply hydrogen in large quantities, catalyst bonding and deactivation, etc., to optimize reaction efficiency, optimize material utilization, reduce The effect of aggregation and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

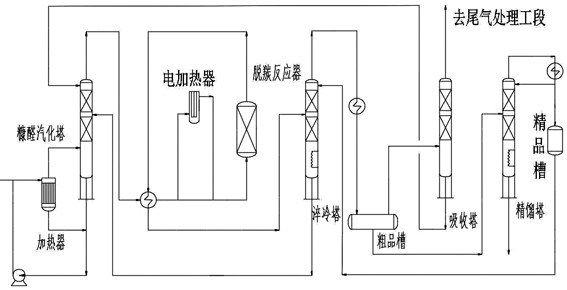

[0037] (1) Feed furfural into the furfural vaporization tower heater at an amount of 320Kg / h, furfural is preheated to 120°C and then enters the vaporization tower, and is fed into the furfural vaporization tower with 55Nm 3 / h into hydrogen for protection (reduce the partial pressure of furfural in the gas phase, thereby lowering the vaporization temperature of furfural, reducing the polymerization and coking of furfural, and reducing the consumption of furfural), and control the temperature in the furfural vaporization tower at 145°C;

[0038] (2) The gas phase from the furfural vaporization tower goes through the heat exchanger (180°C) and enters the electric heater to be heated to 290°C, then enters the decarbonylation reactor, and flows into the decarbonylation reactor with 55Nm 3 / h into hydrogen for protection, control the temperature in the decarbonylation reactor to 300°C and the pressure to 0.02Mpa, under the action of noble metal catalyst (palladium chloride), furfur...

Embodiment 2

[0042] (1) Feed furfural into the furfural vaporization tower heater at an amount of 300Kg / h. Furfural is preheated to 112°C and enters the vaporization tower, and is fed into the furfural vaporization tower with 52Nm 3 / h Introduce hydrogen for protection (reduce the partial pressure of furfural in the gas phase, thereby reducing the vaporization temperature of furfural, reducing the polymerization and coking of furfural, and reducing the consumption of furfural), and control the temperature in the furfural vaporization tower at 130°C;

[0043] (2) The gas phase from the furfural vaporization tower goes through the heat exchanger (162°C) and enters the electric heater to be heated to 265°C, then enters the decarbonylation reactor, and flows into the decarbonylation reactor with 52Nm 3 / h into hydrogen for protection, control the temperature in the decarbonylation reactor at 265°C and the pressure at 0.01Mpa, under the action of noble metal catalyst (palladium chloride), furfura...

Embodiment 3

[0047] (1) Feed furfural at 350Kg / h into the heater of the furfural vaporization tower. Furfural is preheated to 135°C and then enters the vaporization tower. 3 / h into hydrogen for protection (reduce the partial pressure of furfural in the gas phase, thereby lowering the vaporization temperature of furfural, reducing the polymerization and coking of furfural, and reducing the consumption of furfural), and control the temperature in the furfural vaporization tower at 155°C;

[0048] (2) The gas phase from the furfural vaporization tower goes through the heat exchanger (220°C) and enters the electric heater to be heated to 330°C, then enters the decarbonylation reactor, and flows into the decarbonylation reactor with 60Nm 3 / h into hydrogen for protection, control the temperature in the decarbonylation reactor to 330°C and the pressure to 0.03Mpa, under the action of noble metal catalyst (platinum chloride), furfural decarbonylation reaction occurs to generate crude gas phase fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com