Preparation method of gel emulsion and low-density fluorescent porous metal complex material prepared by templating gel emulsion

A technology of gel emulsion and porous metal, applied in the direction of luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 3.9g of the organic ligand shown in formula III-1 in 172g of p-xylene at 65°C, and dissolve 1g of terbium nitrate pentahydrate in 800g of distilled water, wherein the terbium nitrate pentahydrate, the organic ligand, and p-xylene The mass ratio is 1:3.9:172, the amount of distilled water is 82% of the total mass of distilled water and p-xylene, and the two solutions are mixed and stirred until a gel emulsion is formed.

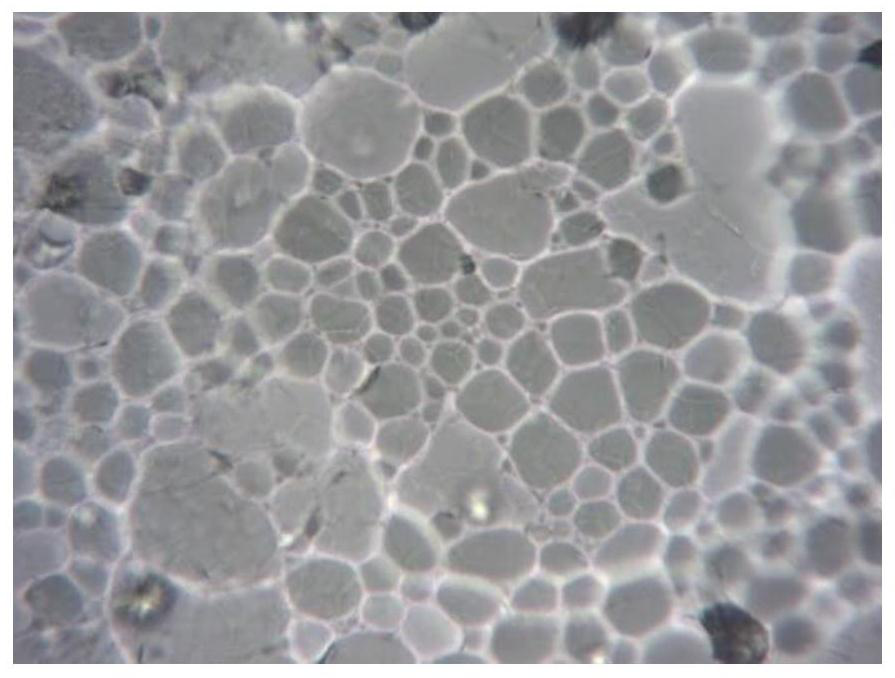

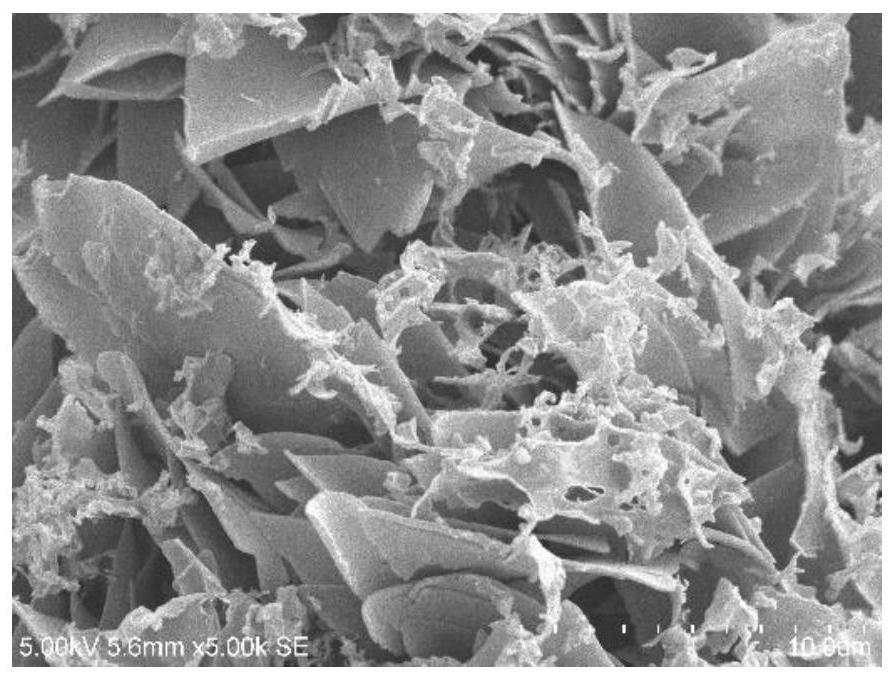

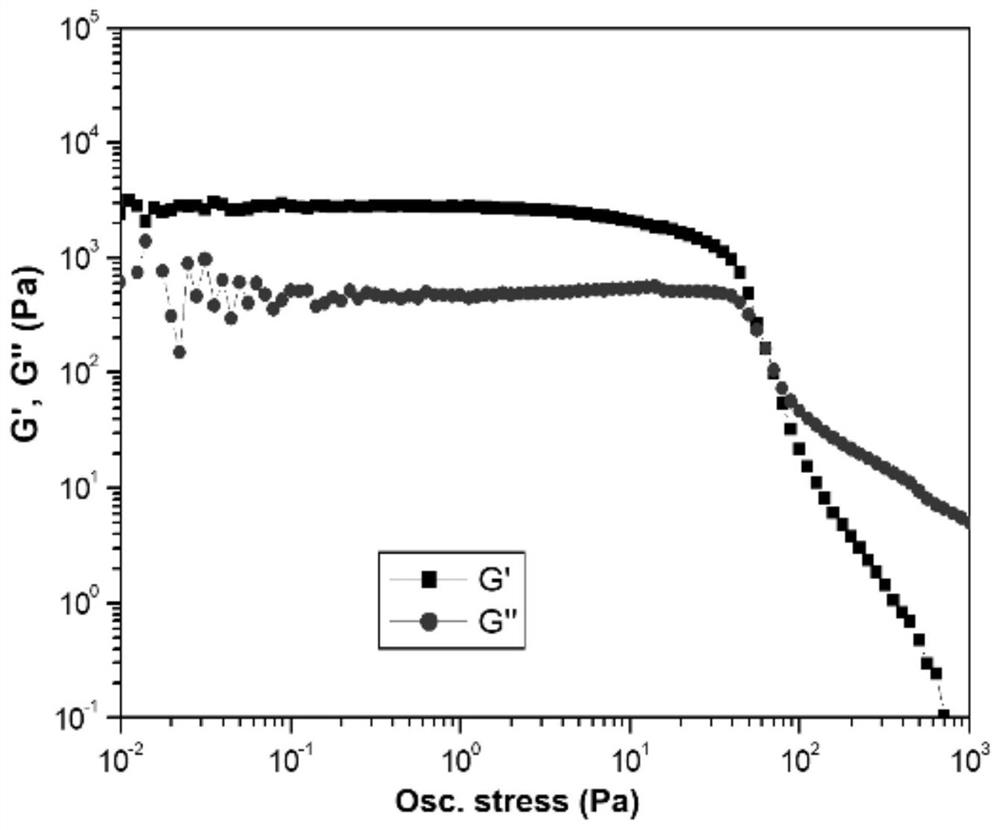

[0042] The prepared gel emulsion was characterized by ISH500 optical microscope and AR-G2 rheometer, and the dried gel emulsion was characterized by S-3400N II type environmental scanning electron microscope. The results are shown in Figure 1~4 . Depend on figure 1 It can be seen that the prepared gel emulsion exhibits a typical gel emulsion microstructure, and the dispersed droplets squeeze each other to make its shape irregular; figure 2 It is the scanning electron microscope picture after the freeze-drying of the prepared gel emulsion, w...

Embodiment 2

[0044] Dissolve 3.9g of the organic ligand shown in formula III-1 in 175g of benzene at 65°C, and dissolve 1g of europium nitrate hexahydrate in 800g of distilled water, wherein the mass ratio of europium nitrate hexahydrate, organic ligand, and benzene is 1 : 3.9: 175, the amount of distilled water is 82% of the total mass of distilled water and benzene, and the two solutions are mixed and stirred until a gel emulsion is formed.

Embodiment 3

[0046] Dissolve 3.9g of the organic ligand shown in formula III-1 in 175g of toluene at 65°C, and dissolve 1g of terbium nitrate pentahydrate in 800g of distilled water, wherein the mass ratio of terbium nitrate pentahydrate, organic ligand, and toluene is 1 : 3.9: 173, the amount of distilled water is 82% of the total mass of distilled water and toluene, and the two solutions are mixed and stirred until a gel emulsion is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com