Preparation method of blocky zirconium oxide aerogel

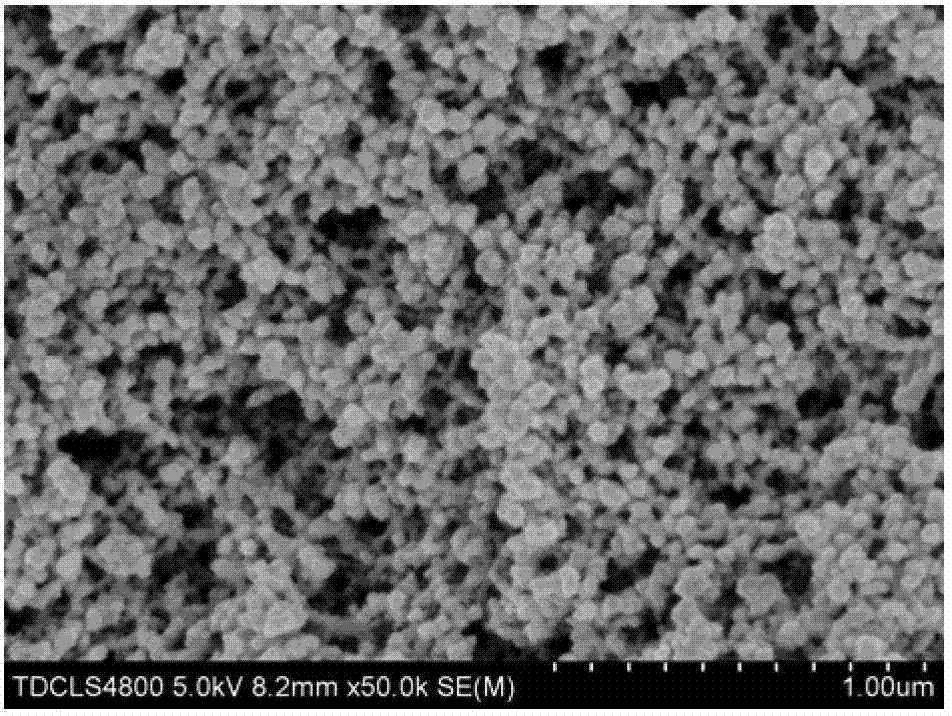

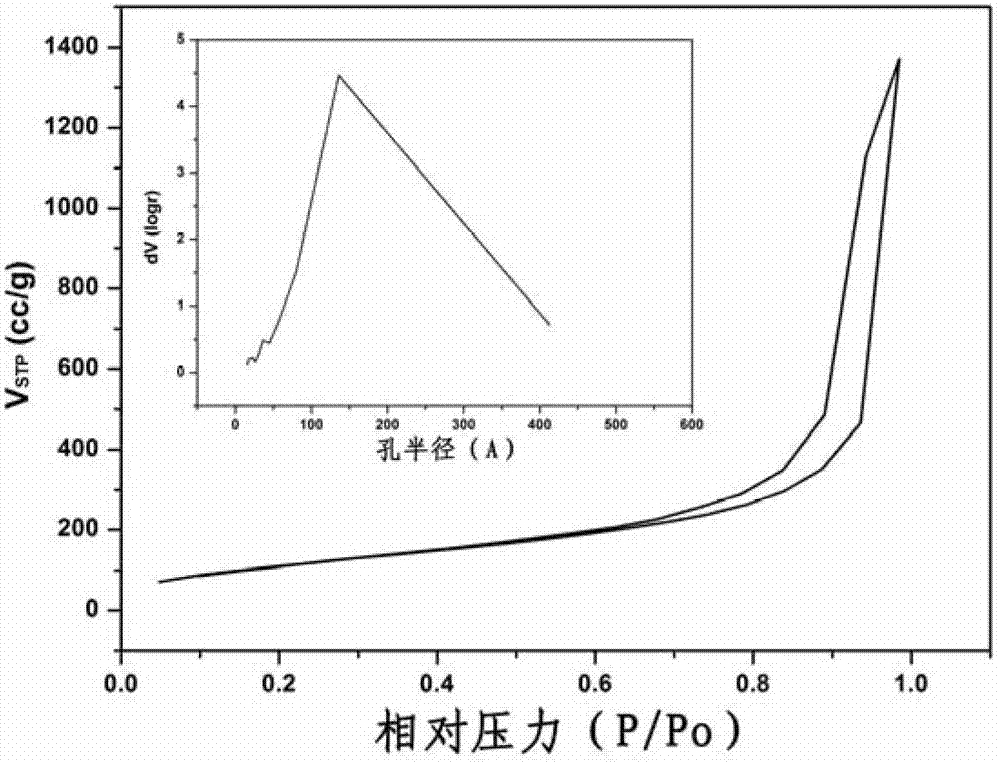

A gel and block technology, applied in zirconia and other directions, can solve the problems of fast hydrolysis rate, low structural strength, high price, etc., and achieve the effects of broad application prospects, uniform pore size distribution, and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Zirconium oxychloride is selected for zirconium inorganic salt, ethanol is selected for alcohol solvent, acetic acid is selected for chelating agent, polyethylene glycol 600 is selected for dispersant, formamide is selected for drying control agent, propylene oxide is selected for epoxy, and 80vol% surface modification solution is selected Tetraethyl orthosilicate ethanol solution, ethanol is selected as the low critical point solvent; the following steps are carried out in sequence: 1) Weigh a certain amount of ZrOCl 2 ·8H 2 O, at a temperature of 20-35°C, dissolve in a mixed solution of ethanol and water, the concentration of the precursor is 0.3mol / L, and the volume ratio of ethanol and water is 4:1.

[0026] 2) After the zirconium oxychloride is completely dissolved, add anion exchange resin to the precursor solution according to the volume ratio of the resin to the precursor solution obtained in step 1) at 1:5, stir for 30 minutes, let stand for 2 hours, and then fil...

Embodiment 2

[0035] Zirconium oxynitrate is selected as zirconium inorganic salt, isopropanol is selected as alcohol solvent, oxalic acid is selected as chelating agent, polyethylene glycol 600 is selected as dispersant, N,N-dimethylformamide is selected as drying control agent, and propylene oxide is selected as epoxy , surface modification solution selects 40vol% methyltrimethoxysilane ethanol solution for use, low critical point solvent selects isopropanol for use; Carry out the following steps successively:

[0036] 1) Weigh a certain amount of ZrO(NO 3 ) 2 2H 2 O, at a temperature of 20-35°C, dissolve in a mixed solution of isopropanol and water, the concentration of the precursor is 0.1mol / L, and the volume ratio of isopropanol to water is 2:1.

[0037] 2) After zirconium oxynitrate is completely dissolved, add anion exchange resin in the precursor solution according to the volume ratio of the resin to the precursor solution obtained in step 1) of 1:10, stir for 40 minutes, let sta...

Embodiment 3

[0045] Use zirconium nitrate as the zirconium inorganic salt, n-butanol as the alcohol solvent, citric acid as the chelating agent, polyethylene glycol 600 as the dispersant, glycerol as the drying control agent, epichlorohydrin as the epoxy, and surface modification solution Select 20vol% dimethyldiethoxysilane ethanol solution, and select ethanol as the low critical point solvent; carry out the following steps in sequence:

[0046] 1) Weigh a certain amount of Zr(NO 3 ) 4 ·5H 2 O, at a temperature of 20-35°C, dissolve in a mixed solution of n-butanol and water, the precursor concentration is 0.5mol / L, and the volume ratio of n-butanol and water is 8:1.

[0047] 2) After zirconium nitrate is completely dissolved, add anion exchange resin in the precursor solution according to the volume ratio of the resin and the precursor solution obtained in step 1) of 1:10, stir for 60 minutes, let stand for 4 hours, and then filter out the resin to obtain ion exchange After the precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com