Method for preparing potassium hexatitanate whisker composite SiO2 aerogel heat insulating material

A technology of potassium hexatitanate whiskers and thermal insulation materials, which is applied in the field of thermal insulation materials, and can solve problems such as affecting the bonding effect, unevenness, and increased thermal conductivity, so as to improve mechanical properties and structural stability, and block infrared radiation Effect of heat transfer and thermal conductivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

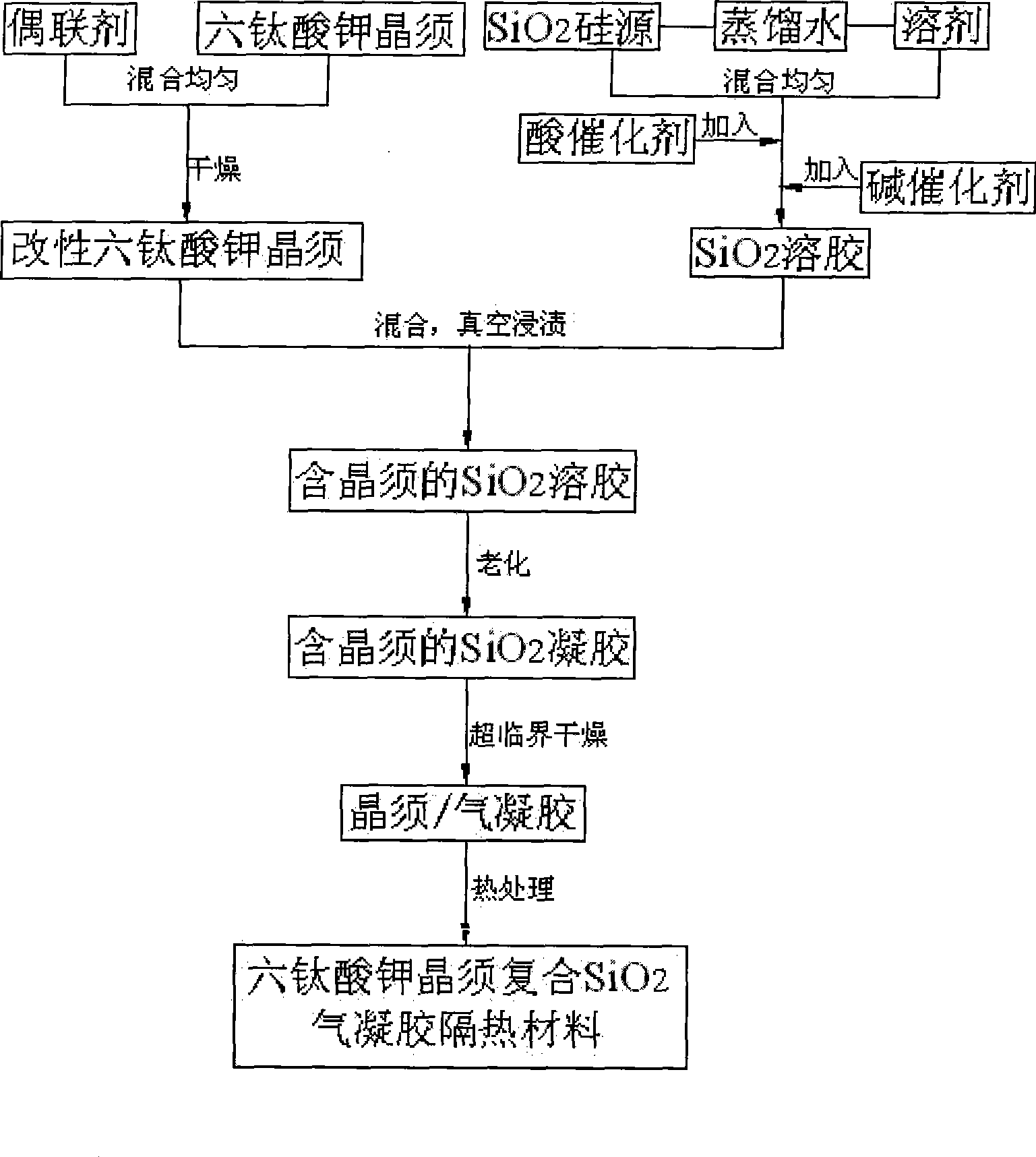

Method used

Image

Examples

Embodiment 1

[0031] First, dry a certain amount of potassium hexatitanate whiskers at 120°C for 4 hours, then pour absolute ethanol into a container containing baked potassium hexatitanate whiskers to make a suspension, and then dry it at 80°C Stir with a stirrer for 30 minutes under a certain environment, while stirring, slowly pour 2% KH-550 of potassium hexatitanate whisker mass into it within 5 minutes, dry and grind to obtain modified hexatitanium Potassium acid whiskers, sealed for later use;

[0032] Re-preparation of SiO 2 Gel precursor. At room temperature, according to the molar ratio of TEOS: distilled water: absolute ethanol = 1.0:2.0:8.0, mix evenly in the container, then add an appropriate amount of 1wt% hydrochloric acid, and let it stand for 2 hours to make SiO 2 The silicon source is fully hydrolyzed, and the pH value is controlled at 3 to 4; then an appropriate amount of 1wt% ammonia water is added, and the stirring is stopped after 2 hours to obtain SiO 2 Sol;

[0033]...

Embodiment 2

[0035] First, dry a certain amount of potassium hexatitanate whiskers at 120°C for 4 hours, then pour absolute ethanol into a container containing baked potassium hexatitanate whiskers to make a suspension, and then dry it at 80°C Stir with a stirrer for 30 minutes under a certain environment, while stirring, slowly pour 2% NDZ-101 of the mass of potassium hexatitanate whiskers into it within 5 minutes, dry and grind to obtain the modified hexatitanium Potassium acid whiskers;

[0036] Re-preparation of SiO 2 Gel precursor. At room temperature, according to the molar ratio of TEOS: distilled water: absolute ethanol = 1.0:1.0:6.0, mix evenly in the container, then add an appropriate amount of 1wt% hydrochloric acid, and let it stand for 2 hours to make SiO 2 The silicon source is fully hydrolyzed, and the pH value is controlled at 3 to 4; then an appropriate amount of 1wt% ammonia water is added, and the stirring is stopped after 2 hours to obtain SiO 2 Sol;

[0037] SiO 2...

Embodiment 3

[0039] First, dry a certain amount of potassium hexatitanate whiskers at 120°C for 4 hours, then pour absolute ethanol into a container containing baked potassium hexatitanate whiskers to make a suspension, and then dry it at 80°C Stir with a stirrer for 30 minutes under a certain environment, while stirring, slowly pour 2% NDZ-201 of potassium hexatitanate whisker mass into it within 5 minutes, dry and grind to obtain modified hexatitanium Potassium acid whiskers;

[0040] Re-preparation of SiO 2 Gel precursor. At room temperature, according to the molar ratio of TEOS: distilled water: absolute ethanol = 1.0:2.0:8.0, mix evenly in the container, then add an appropriate amount of 2wt% hydrochloric acid, and let it stand for 2 hours to make SiO 2 The silicon source is fully hydrolyzed, and the pH value is controlled at 3 to 4; then an appropriate amount of 2wt% ammonia water is added, and the stirring is stopped after stirring for 2 hours to obtain SiO 2 Sol;

[0041] SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com