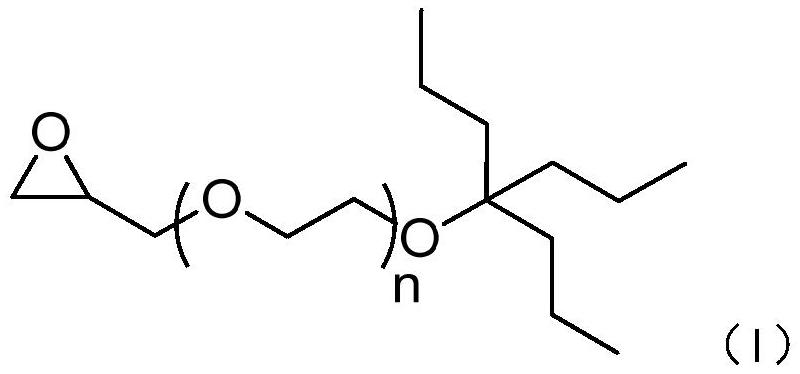

Epoxy curing agent that can be used for zinc-rich primer and its preparation method and application

A technology of epoxy curing agent and zinc-rich primer, which is used in epoxy resin coatings, coatings, anti-corrosion coatings, etc. Surface drying speed and other issues, to achieve the effect of improving coating ability, suitable surface drying time, and low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

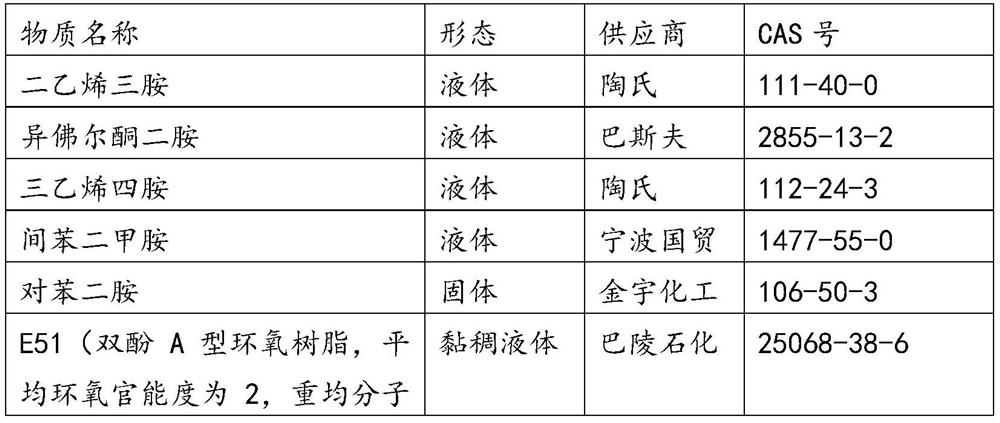

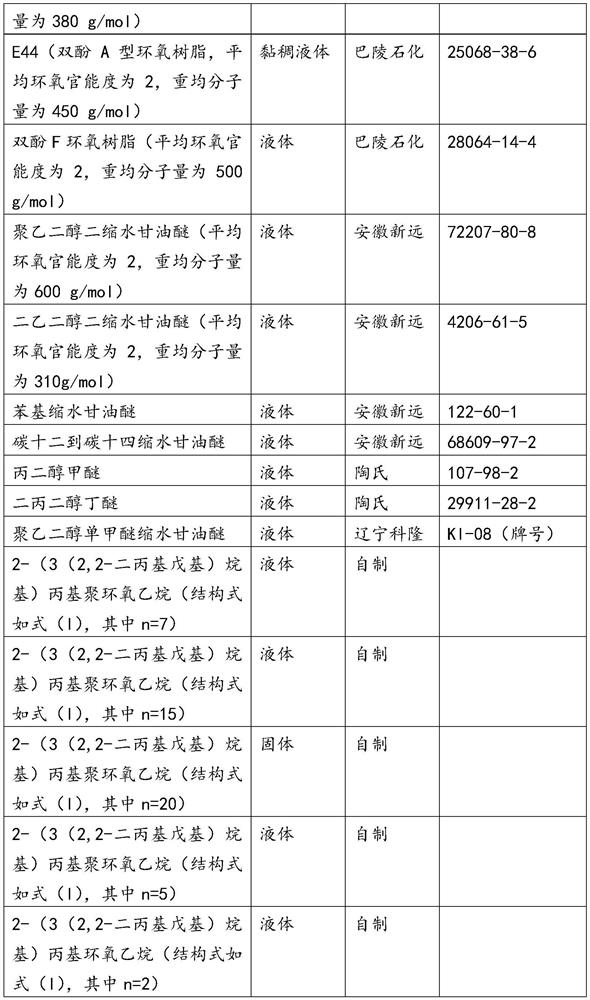

[0083] Example 1: Add 300g of diethylenetriamine (polyamine, its molar ratio to the polyepoxide is 7.9:1) in the reaction flask, preheat the temperature to 100°C, and use 140g of E51 (polyepoxide) The peristaltic pump is gradually dropped into the reaction bottle, the dropping time lasts for 2 hours, and the heat preservation is continued for 1 hour; use a vacuum pump to carry out vacuum distillation to remove 200g of excess amine; then add 100g of propylene glycol methyl ether to the system for dilution and adjust the temperature to 80°C, after the temperature was stabilized at 80°C, 40g butyl glycidyl ether and 20g 2-(3(2,2-dipropylpentyl)alkyl)propylpolyethylene oxide ( n=7) Gradually drop into the reaction bottle for 1 hour, keep warm at 80°C for half an hour; cool down to 50°C, add 10g of isophoronediamine into the system, and stir for 10min to obtain 410g of epoxy curing agent.

[0084] Curing agent viscosity: 170cP Solid content: 75.6% pH: 9.6

Embodiment 2

[0085] Example 2: Add 225g triethylenetetramine (polyamine, its molar ratio to polyepoxide is 4:1) in the reaction flask, preheat the temperature to 80°C, and use 170g E44 (polyepoxide) The peristaltic pump is gradually dripped into the reaction bottle, the dripping time lasts for 3 hours, and the heat preservation is continued for 0.5 hours; use a vacuum pump to carry out vacuum distillation to remove 135g of excess amine; then add 170g of propylene glycol methyl ether to the system for dilution and adjust the temperature to 90°C, and after the temperature was stabilized at 90°C, 50g of phenyl glycidyl ether and 20g of 2-(3(2,2-dipropylpentyl)alkyl)propylpolyethylene oxide ( n=20) was gradually dropped into the reaction bottle, the dropping time was 1 hour, and the temperature was kept at 90°C for half an hour; the temperature was lowered to 40°C, 3g of p-phenylenediamine was added into the system, and 503g of epoxy curing agent was obtained after stirring for 30min.

[0086]...

Embodiment 3

[0087] Example 3: Add 465g of diethylenetriamine (polyamine, its molar ratio to polyepoxide is 10.46:1) in the reaction flask, preheat the temperature to 70°C, and 200g of E51 and polyethylene glycol dishrink Glycerol ether mixture (mass ratio 1:1) (polyepoxide) was gradually dripped into the reaction flask using a peristaltic pump, the dripping time continued for 1 hour, and continued to keep warm for 1 hour, and the vacuum pump was used for vacuum distillation to remove excess amine Remove 390g, then add 100g propylene glycol methyl ether to the system for dilution, adjust the temperature to 100°C, and after the temperature is stabilized at 100°C, use a peristaltic pump to add 25g of carbon dodecyl to carbon tetradecyl glycidyl ether and 70g of 2 -(3(2,2-dipropylpentyl)alkyl)propylpolyethylene oxide (n=15) was gradually dripped into the reaction flask, the time of the addition was 0.5 hours, the temperature was kept at 100°C for half an hour, and the temperature was lowered t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com