Hydrophobic and light-operated antibacterial waterborne polyurethane composite emulsion and preparation method and application thereof

A technology of water-based polyurethane and composite emulsion, which is applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of hydrophobic type and light control antibacterial type aqueous polyurethane composite emulsion of the present invention comprises the following steps,

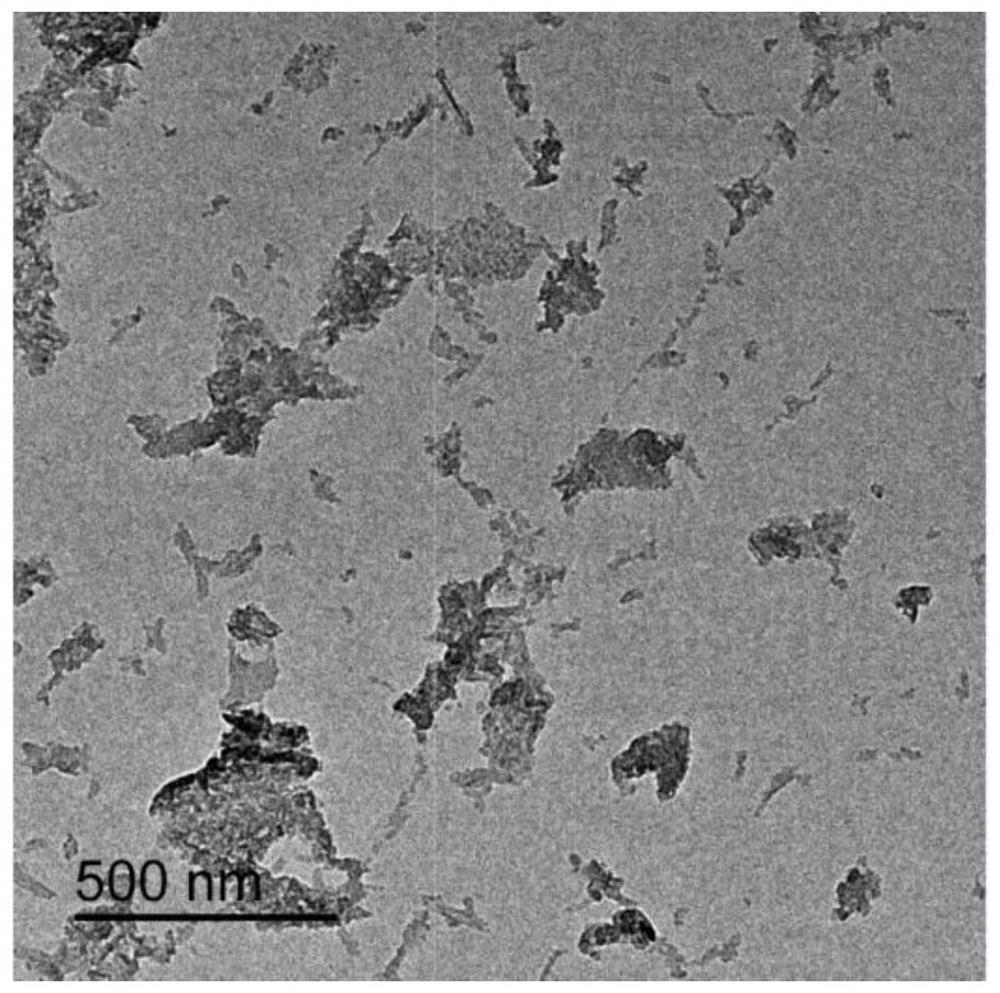

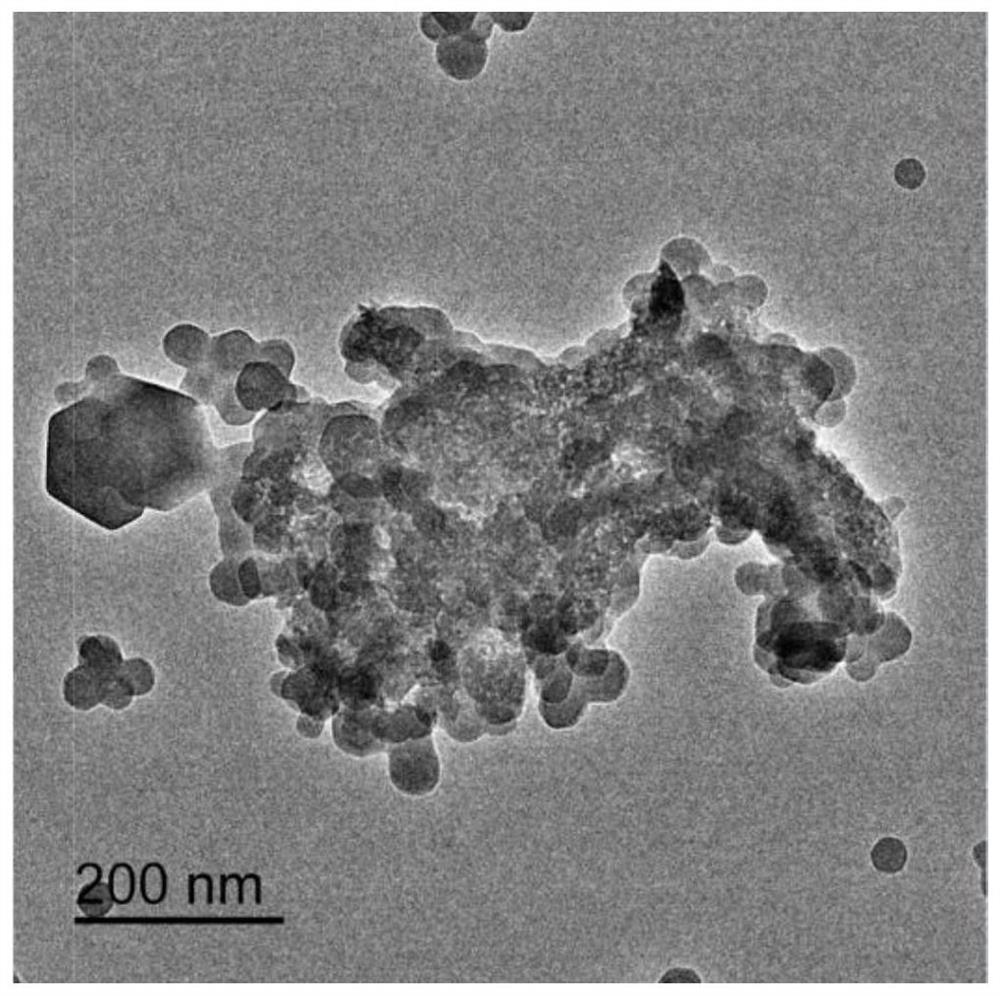

[0030] Step 1, weigh 10-20g of dicyandiamide in a crucible, place it in a muffle furnace and heat it to 470-550°C at 2.3-4.6°C / min, and keep it for 4-6h to obtain yellow block g-C 3 N 4 , using concentrated HNO 3 Etching and stripping to prepare flake g-C 3 N 4 . In the prepared g-C 3 N 4 Adding Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole (2-MIm) were stirred at room temperature for 6-8 hours, g-C 3 N 4 The concentration of nanosheets is 1-2mg / mL, dicyandiamide, 2-MIm and Zn(NO 3 ) 2 ·6H 2 The mass ratio of O (10-20): (165-248): (60-90). Then the obtained white emulsion was centrifuged, washed 2 to 3 times with absolute ethanol, and the obtained g-C was dispersed in pure water. 3 N 4 @ZIF-8 nanocomposite concentration to 0.5 ~ 2mg / mL.

[0031] Step 2, drying polycaprolactone a...

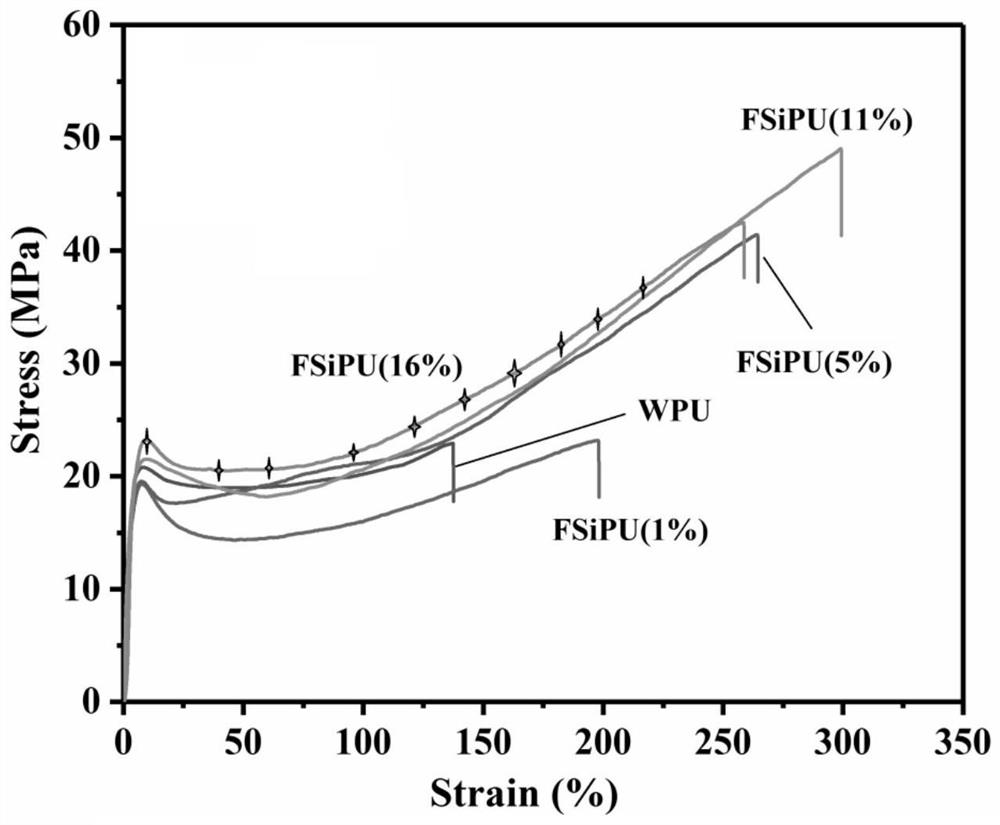

Embodiment 1

[0040] A kind of preparation method of hydrophobic type and light control antibacterial type aqueous polyurethane composite emulsion of the present invention, concrete preparation method comprises the following steps,

[0041] Step 1, preparation of FSiPU composite emulsion,

[0042] Step 1a, dry PCL1000 and PDSF in an oven at 120°C to remove water for 2 hours to obtain anhydrous PCL1000 and PDSF, and anhydrous PDSF and PCL1000 are in liquid state at this time;

[0043] Step 1b, add 3.88g of anhydrous PCL1000 and 1.056g of anhydrous DMBA into a 250mL round bottom flask, insert a mechanical stirring paddle, a spherical condenser and a glass stopper to keep the whole system in a closed state, and place the flask in a water bath The temperature was raised to 60°C in the middle and kept for 0.5h, the stirring rate was adjusted to 300rpm, the temperature was raised to 80°C after stirring for 30min, 4.446g IPDI was added dropwise at 0.05mL / s, and then 20μL of catalyst DBTDL was adde...

Embodiment 2

[0050] A kind of preparation method of hydrophobic type and light control antibacterial type aqueous polyurethane composite emulsion of the present invention, concrete preparation method comprises the following steps,

[0051] Step 1, preparation of FSiPU composite emulsion,

[0052] Step 1a, dry PCL1000 and PDSF in an oven at 120°C to remove water for 2 hours to obtain anhydrous PCL1000 and PDSF, and anhydrous PDSF and PCL1000 are in liquid state at this time;

[0053] Step 1b, add 3.88g of anhydrous PCL1000 and 1.056g of anhydrous DMBA into a 250mL round bottom flask, insert a mechanical stirring paddle, a spherical condenser and a glass stopper to keep the whole system in a closed state, and place the flask in a water bath The temperature was raised to 60°C in the medium and then kept for 0.5h, the stirring rate was adjusted to 300rpm, the temperature was raised to 80°C after stirring for 30min, 4.446g IPDI was added dropwise at 0.05mL / s, and then 20μL of catalyst DBTDL was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com