A flow electrolysis method for stably realizing high-efficiency electrocatalytic carbon dioxide reduction under high current conditions

A technology of electrocatalytic carbon dioxide and electrolysis method, applied in electrolysis components, electrolysis process, electrolysis organic production, etc., can solve the problems of poor system stability and low catalytic selectivity, improve stability, optimize loading mode, and promote initial activation effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

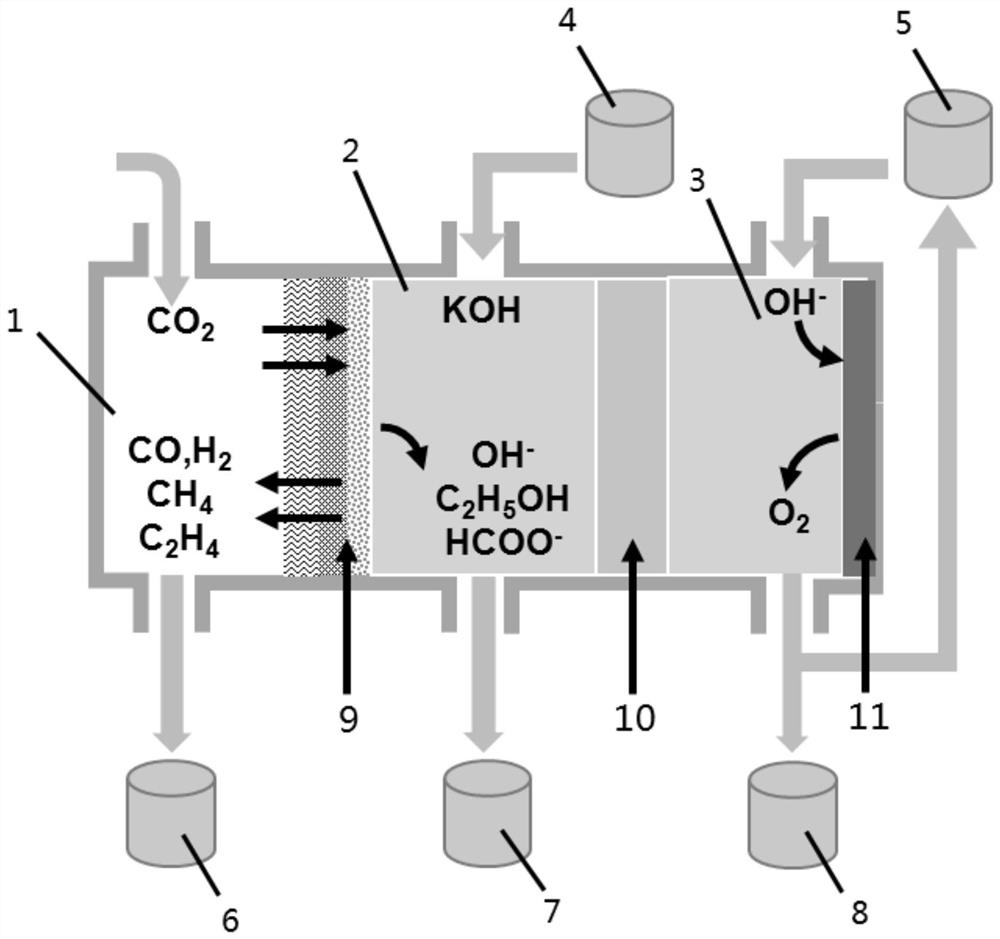

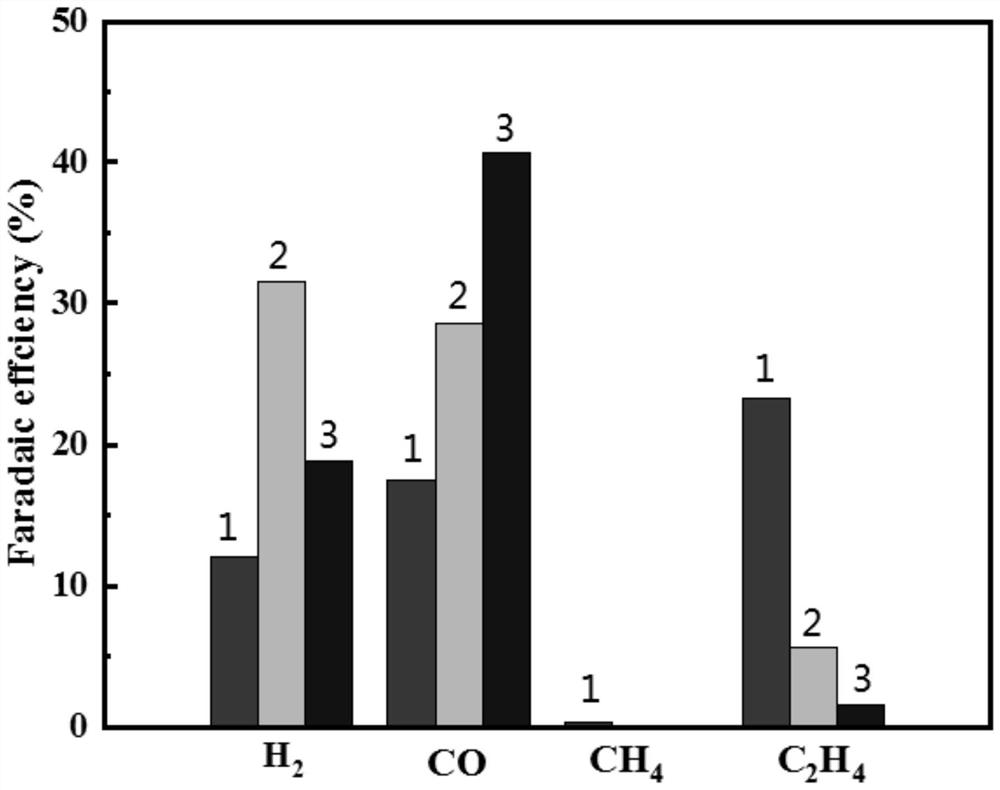

[0029] Specific implementation mode one: combine figure 1 Specifically, this embodiment is a flow electrolysis method applied to stably realize high-efficiency electrocatalytic carbon dioxide reduction under high current conditions, which is completed according to the following steps:

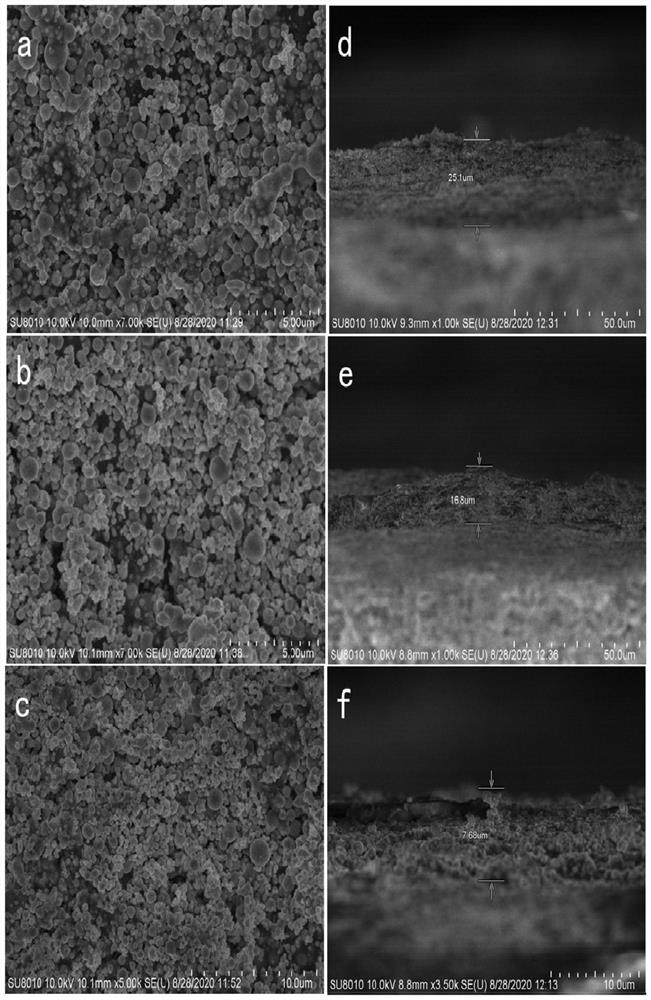

[0030] 1. Preparation of gas diffusion electrode:

[0031] ① Weighing: Dissolve the copper salt and iron salt in the solvent, then add the surfactant, and stir and mix for 10min to 120min at a rotational speed of 500rpm to 1000rpm to obtain a reaction solution;

[0032] The molar ratio of the copper salt to the iron salt is (1~999):1; the volume ratio of the amount of the copper salt to the solvent described in step 1. is (0.5~2)mmol:100mL The volume ratio of the amount of the substance of the surfactant and the solvent described in step 1. is (0.5~2)mmol:100mL;

[0033] ②. Reduction: Under the condition of ice-water bath, pass argon or nitrogen gas into the reaction solution for 10-60 minute...

specific Embodiment approach 2

[0050] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the solvents described in step one 1. and step one 2. are all alcohol-containing organic solvents or water; the described alcohol-containing organic solvents are triethylene glycol Alcohol, ethylene glycol or glycerol; The solvent described in step one 5. is the mixed solution or ethanol of Virahol and Nafion; The volume ratio of Virahol and Nafion in the mixed solution of described Virahol and Nafion is ( 10~100):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0051] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the copper salt described in Step 1. is copper nitrate, copper acetate, copper acetylacetonate, copper chloride, copper sulfate or acetic acid nitrite copper. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com