Method for preparing two-dimensional transition metal chalcogenide in-plane heterojunction

A transition metal chalcogenide and compound technology, applied in chemical instruments and methods, metal material coating process, gaseous chemical plating, etc., can solve problems such as interface pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

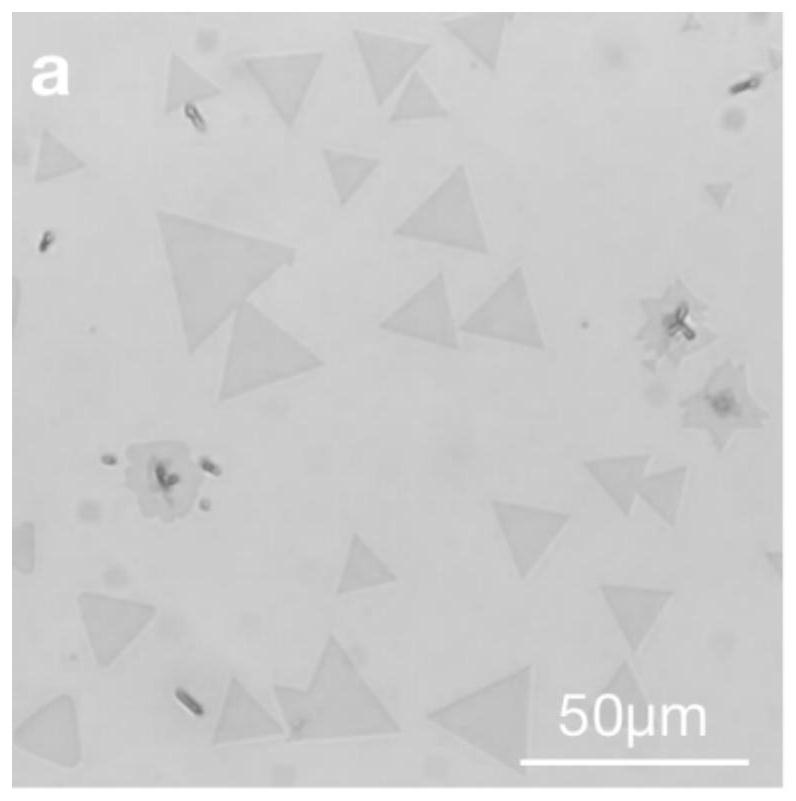

[0037] Below in conjunction with accompanying drawing and example the present invention is described in further detail:

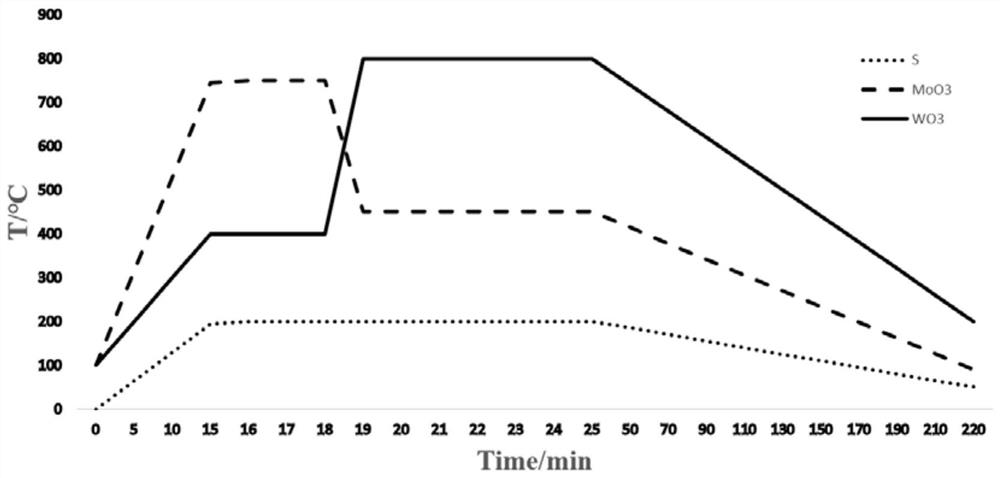

[0038] Step 1: Weigh 0.5gS powder, 10mgWO 3 Solid powder and 6mgMoO 3 solid powder, WO 3 Mix solid powder with NaCl solid powder at a ratio of 5:1, MoO 3 The solid powder is mixed with the NaCl solid powder at a ratio of 6:1, and then put into three quartz boats respectively;

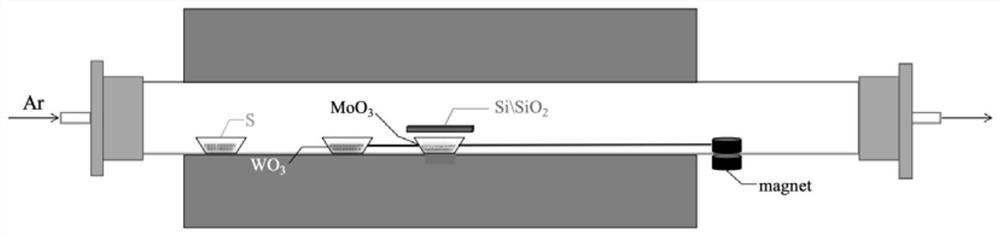

[0039] Step 2: Sequentially test the cut Si / SiO in the environment of detergent, deionized water and absolute ethanol 2 The substrate was ultrasonically cleaned, and then the surface of the substrate was flushed with nitrogen, and then the substrate was cleaned in a plasma oxygen ion cleaner for 5 minutes. Treated Si / SiO 2 The substrate is placed upside down on the quartz rack, which is located directly above the heating center. There is a small square hole of 1cm x 1cm in the middle of the quartz rack to ensure that the substrate inverted on the quartz rack is close enough to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com