Graphene washable long-acting antiviral fabric and preparation method thereof

A graphene and water-resistant technology, applied in the direction of hydraulic acupuncture, fabric surface trimming, plant fibers, etc., can solve the problems of far lower antibacterial and anti-virus performance, and achieve improved water resistance and service life, and high load durability. degree, the effect of increasing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of graphene washable long-acting antiviral fabric, comprising the following steps:

[0029] S1. In-situ growth of polyvinylpyrrolidone on the surface of graphene to obtain a graphene / polyvinylpyrrolidone composite.

[0030] In step S1, the preparation method of the graphene / polyvinylpyrrolidone composite includes: adding graphene nanosheets and dispersants with lateral dimensions less than 100nm and thickness less than 10nm to deionized water, ultrasonic dispersion is uniform (graphene content is 1wt%~12wt%); then add N-vinylpyrrolidone monomer and initiator, adjust the pH value of the reaction solution to 9~10, react in a polymerization reactor at 45~60°C for 5~12h, and The polymerized product is centrifuged and dried to obtain the graphene / polyvinylpyrrolidone composite.

[0031]The dispersant is selected from one or more of gelatin, cellulose, and cellulose ether. The initiator is azobisisobutyronitrile or benzoyl...

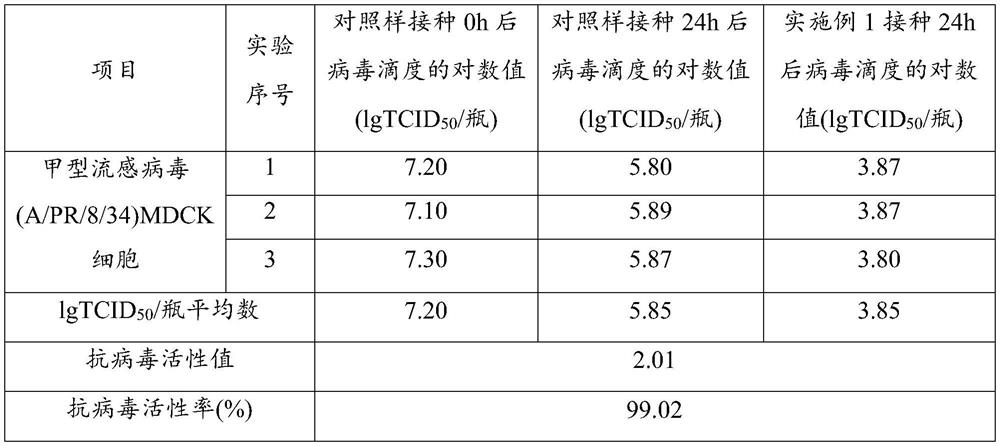

Embodiment 1

[0044] A kind of preparation method of graphene washable long-acting antiviral fabric, comprises the following steps:

[0045] S1. Add graphene nanosheets and hydroxymethyl cellulose with a lateral dimension of about 50nm and a thickness of about 3nm into deionized water, and ultrasonically disperse them evenly (the content of graphene is 7.5wt%, the content of hydroxymethyl cellulose 1.5%); then add N-vinylpyrrolidone monomer (the mass ratio of N-vinylpyrrolidone monomer and graphene nanosheet is 0.4:1) and azobisisobutyronitrile, the pH value of the reaction solution is adjusted To 9-10, react in a polymerization reactor at 50° C. for 8 hours, centrifuge and dry the polymerization product to obtain a graphene / polyvinylpyrrolidone composite.

[0046] S2. Dissolving the graphene / polyvinylpyrrolidone composite obtained in step S1 in deionized water to obtain a finishing solution with a solid content of 8 wt%.

[0047] S3. soaking the cotton fabric in a sodium hydroxide solutio...

Embodiment 2

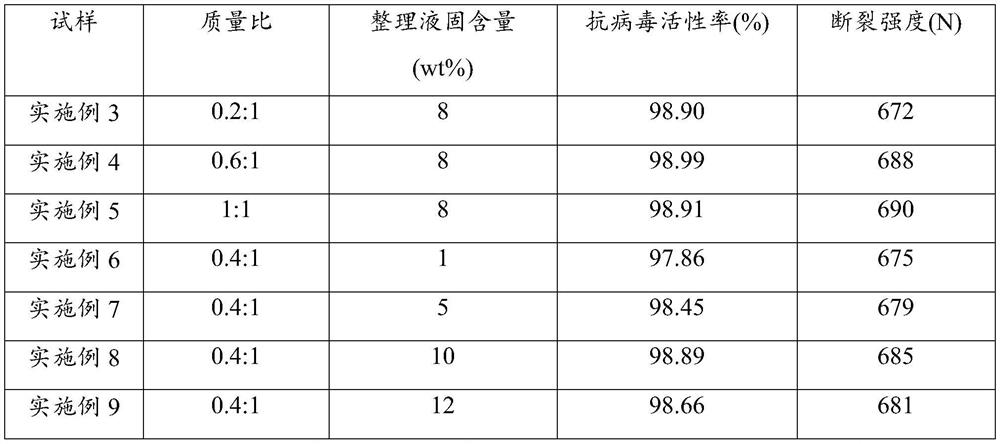

[0056] A method for preparing a graphene washable long-acting antiviral fabric, compared with Example 1, the difference is that in step S4, the apertures of the water needles of the first to fifth spunlaces are all 0.12mm. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0057] After the graphene washable and long-acting antiviral fabric prepared in this example was washed 30 times, the antiviral activity rate was 98.92%, and the fabric breaking strength was 665N. It can be seen that the antiviral activity rate is slightly lower than that of Example 1, and the breaking strength of the fabric is lower than that of untreated cotton fabric. This may be because when the five spunlace jets all use water needles with smaller apertures, the surface of the fabric will repeatedly split into tiny microfibers, which will easily cause fiber breakage and reduce the strength of the fabric. The graphene / polyvinylpyrrolidone composite is also difficult t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com