Carbon paper for gas diffusion layer, preparation method of carbon paper and fuel cell

A gas diffusion layer, carbon paper technology, applied in special paper, battery electrodes, papermaking, etc., can solve the problems of poor hydrophobicity and low porosity, achieve good electrical conductivity and hydrophobicity, improve battery performance, improve air permeability and The effect of drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Another embodiment of the present invention provides a method for preparing carbon paper for a gas diffusion layer as described above, comprising the following steps:

[0048] Mix the porous carbon material into the mesophase pitch, stir and swell fully to prepare the mesophase pitch modified by the porous carbon material;

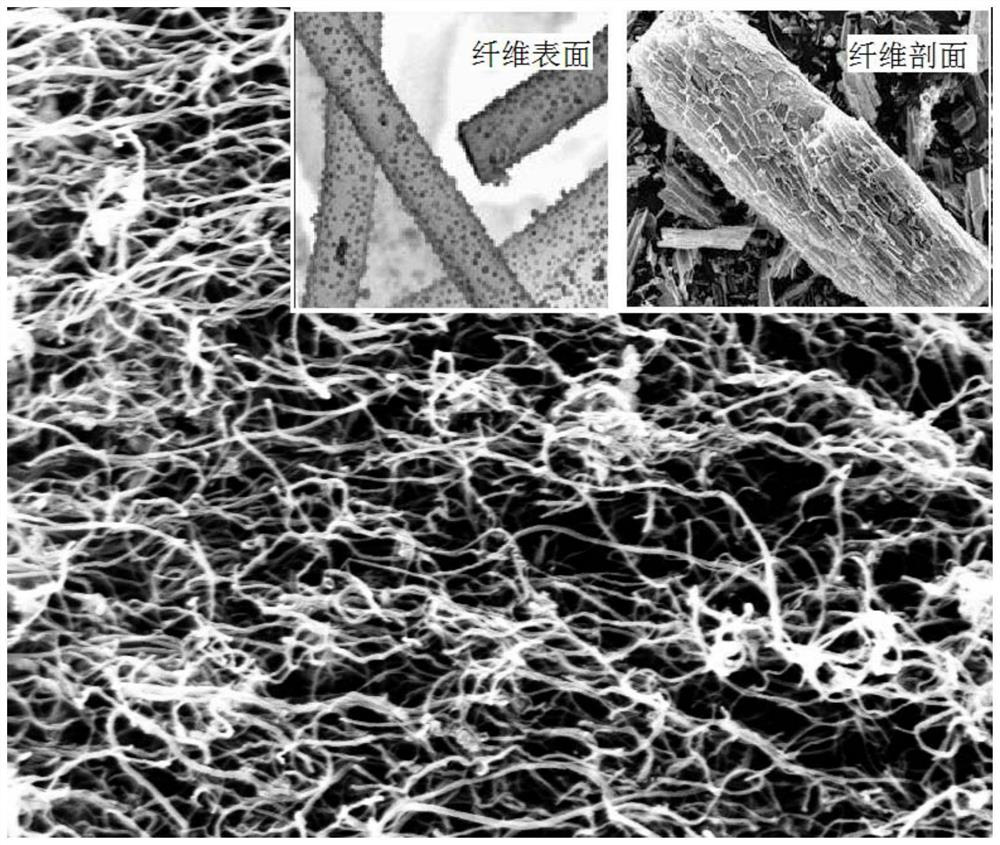

[0049] The mesophase pitch modified by the porous carbon material is melted and spun to prepare the as-spun fiber membrane;

[0050] Preoxidizing the primary fiber membrane to obtain a preoxidized fiber membrane;

[0051] The pre-oxidized fiber membrane is heat-treated under a protective atmosphere to graphitize the fibers in the pre-oxidized fiber membrane to obtain a three-dimensional cross-linked fiber membrane formed by a plurality of carbon fibers.

[0052] According to the preparation method provided by the present invention, the as-spun fiber membrane is prepared by melting and spinning the mesophase pitch modified by the porous carbon mater...

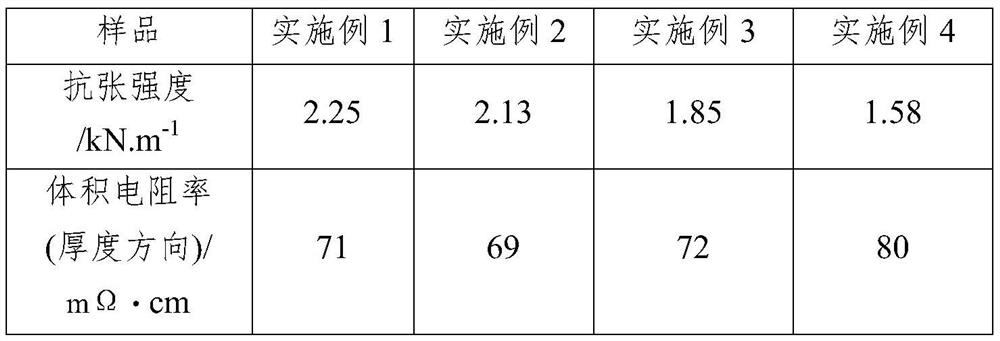

Embodiment 1

[0074] This embodiment is used to illustrate the carbon paper for gas diffusion layer disclosed by the present invention and its preparation method, including the following steps:

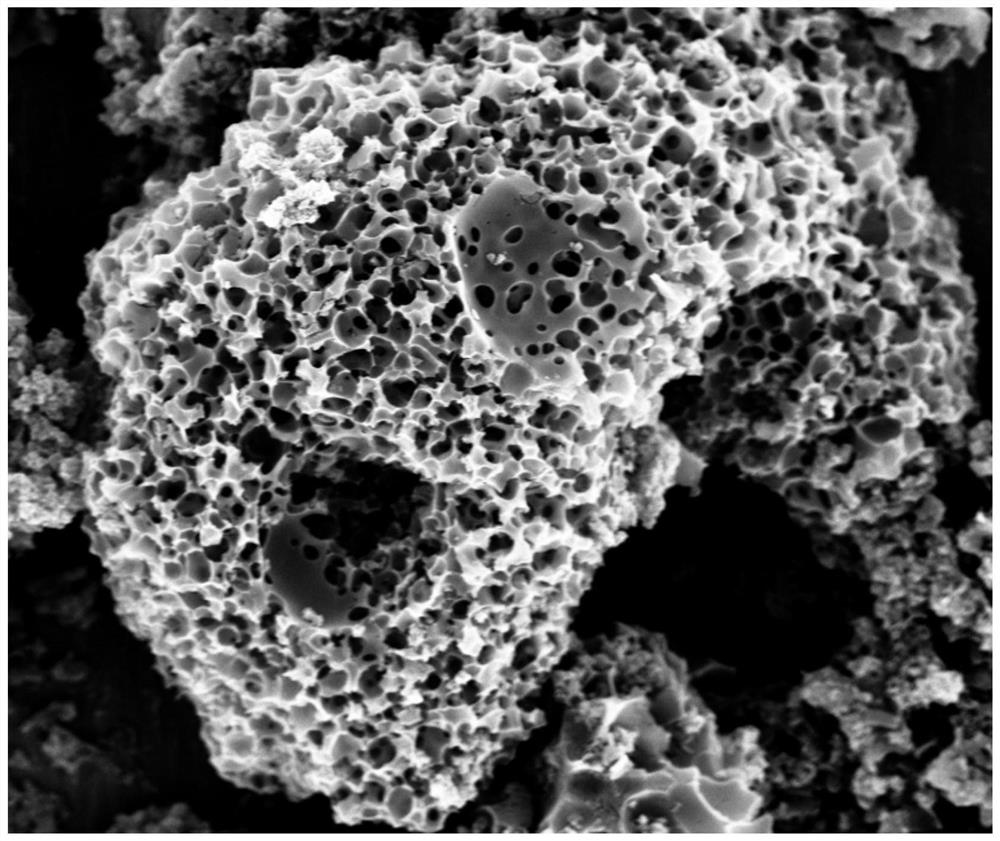

[0075] The three-dimensional graphene microporous carbon is pulverized by a jet mill, so that the average size of the particles is controlled at about 0.5um. The pore diameter range of the three-dimensional graphene microporous carbon is 5-15nm. Take 50g of the three-dimensional graphene microporous carbon Add the powder into 1kg of mesophase pitch (AR pitch), put it into a melting mixer for full stirring, stir at a temperature of 280°C for 30 minutes and then let it stand for swelling. After 30 minutes, take out the modified pitch and put it in a high-speed shearing machine. Shearing for 100 minutes, keeping the temperature at 320°C and rotating speed at 5000r / min during the shearing process, the three-dimensional graphene microporous carbon modified active mesophase pitch was prepared.

[0076] T...

Embodiment 2

[0080] This example is used to illustrate the carbon paper for gas diffusion layer disclosed by the present invention and its preparation method, including most of the operating steps in Example 1, the difference being:

[0081] The three-dimensional graphene microporous carbon is pulverized by a jet mill, so that the average size of the particles is controlled at about 0.1um. The pore diameter range of the three-dimensional graphene microporous carbon is 15-25nm. Take 60g of the three-dimensional graphene microporous carbon Add the powder into 1kg of mesophase pitch (AR pitch), put it into a melting mixer for full stirring, stir at a temperature of 280°C for 30 minutes and then let it stand for swelling. After 30 minutes, take out the modified pitch and put it in a high-speed shearing machine. Shearing for 100 minutes, keeping the temperature at 320°C and rotating speed at 5000r / min during the shearing process, the three-dimensional graphene microporous carbon modified active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com