Calcium supplement composition and preparation method thereof

A composition and preparation technology, which are applied in the field of calcium supplement composition and its preparation, can solve the problems that the calcium supplement effect needs to be further improved, and achieve the effects of improving intestinal health, excellent taste, and remarkable calcium supplement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

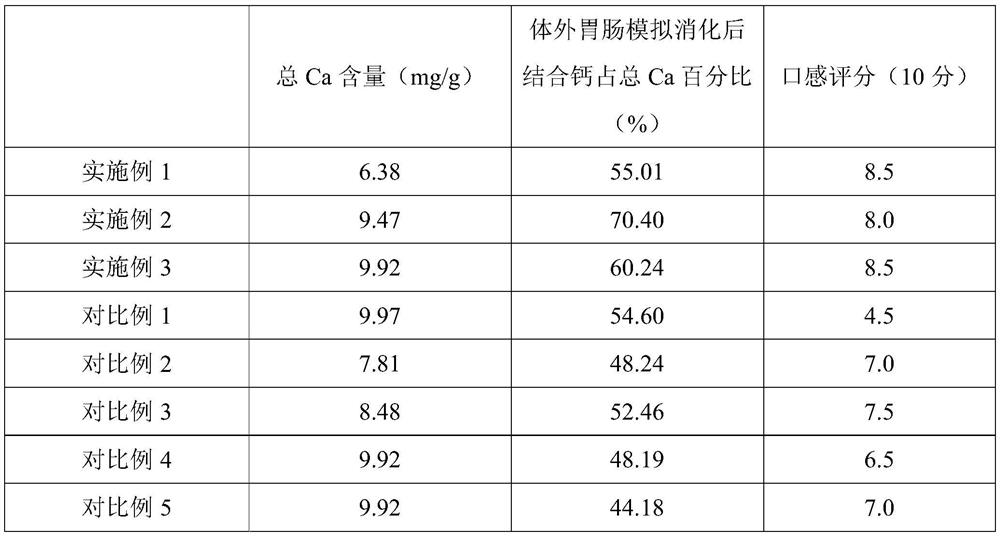

Examples

Embodiment 1

[0039] A composition, in parts by weight, comprising the following components: 15 parts of stachyose, 0.2 parts of casein phosphopeptide, 1 part of calcium carbonate, 0.5 part of L-calcium lactate, 0.2 part of calcium aspartate, mushroom 0.1 part of powder and 60 parts of maltodextrin.

[0040] The preparation technology of described composition comprises the steps:

[0041] (1) Premix casein phosphopeptide, calcium carbonate, L-calcium lactate, calcium aspartate and mushroom powder with 30% maltodextrin for 10 minutes, then add 20% maltodextrin and mix for 20 minutes to obtain premixed Material A;

[0042](2) 20% maltodextrin is passed through a 40-mesh sieve, stachyose is passed through a 80-mesh sieve, premix A is passed through a 60-mesh sieve, and the rest of the maltodextrin is passed through a 60-mesh sieve and mixed. The mixing process of each material is First mix 20% maltodextrin and stachyose, then add premix A after 5 minutes, add the remaining maltodextrin after...

Embodiment 2

[0044] A composition, in parts by weight, comprising the following components: 20 parts of stachyose, 0.6 parts of casein phosphopeptide, 2 parts of calcium carbonate, 1.5 parts of L-calcium lactate, 1.5 parts of calcium aspartate, mushroom 0.4 parts of powder and 100 parts of maltodextrin.

[0045] The preparation technology of described composition comprises the steps:

[0046] (1) Premix casein phosphopeptide, calcium carbonate, L-calcium lactate, calcium aspartate and mushroom powder with 35% maltodextrin for 20 minutes, then add 30% maltodextrin and mix for 40 minutes to obtain premixed Material A;

[0047] (2) 30% maltodextrin is passed through a 60-mesh sieve, stachyose is passed through a 120-mesh sieve, premix A is passed through a 80-mesh sieve, and the rest of the maltodextrin is passed through a 100-mesh sieve and mixed. The mixing process of each material is First mix 30% maltodextrin and stachyose, then add premix A after 9 minutes, add the remaining maltodextr...

Embodiment 3

[0049] A composition, in parts by weight, comprising the following components: 18 parts of stachyose, 0.4 parts of casein phosphopeptide, 1.4 parts of calcium carbonate, 3 parts of L-calcium lactate, 0.6 part of calcium aspartate, mushroom 0.3 parts of powder and 80 parts of maltodextrin.

[0050] The preparation technology of described composition comprises the steps:

[0051] (1) Premix casein phosphopeptide, calcium carbonate, L-calcium lactate, calcium aspartate and mushroom powder with 32% maltodextrin for 15 minutes, then add 25% maltodextrin and mix for 30 minutes to obtain premixed Material A;

[0052] (2) 25% maltodextrin is passed through a 50-mesh sieve, stachyose is passed through a 100-mesh sieve, premix A is passed through a 70-mesh sieve, and the rest of the maltodextrin is passed through a 80-mesh sieve and mixed. The mixing process of each material is as follows: First mix 25% maltodextrin and stachyose, then add premix A after 7 minutes, add the remaining m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com