A method for efficiently treating oil-in-water emulsions with a superhydrophilic nanofiber membrane with a gradient structure

A technology of nanofiber membrane and gradient structure, applied in fiber treatment, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc., can solve the problems of less involvement, and achieve easy operation, strong anti-pollution performance and compatibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

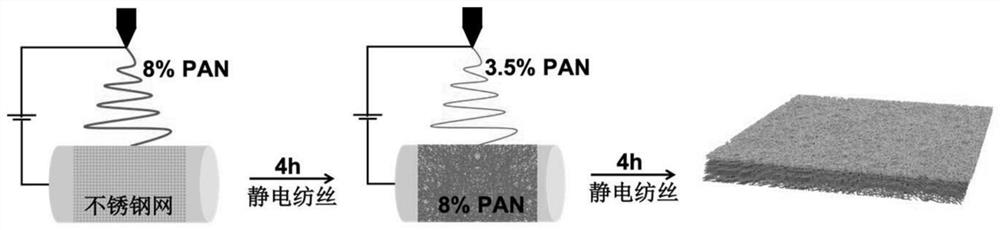

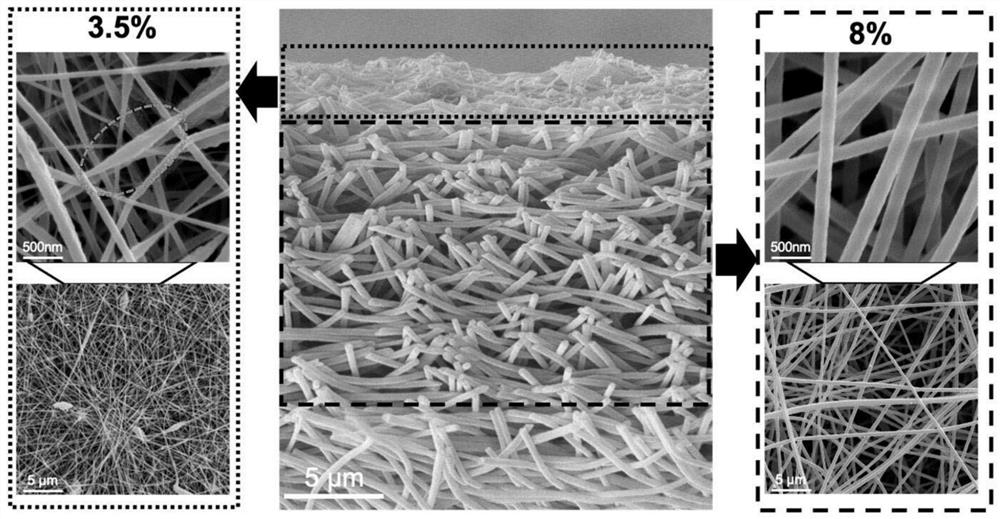

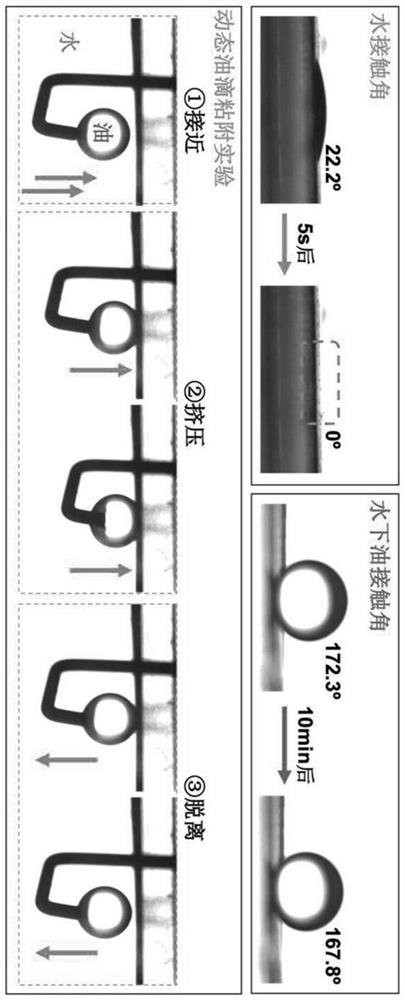

[0049] see attached figure 1 , preparation of superhydrophilic nanofibrous membranes with gradient structure. A 500-mesh stainless steel mesh was selected, cut to a size of 300 mm in length and 210 mm in width, placed in acetone, ethanol, and distilled water in sequence for 5 min each, and dried for later use. Weigh 1.6 g of PAN and dissolve it in 20 mL of N,N-dimethylformamide, and at room temperature with 500 rpm magnetic stirring for 12 h to prepare a first concentration electrospinning working solution with a PAN concentration of 8%, weigh 0.7 g of PAN and dissolve it in 20 mL of N,N-dimethylformamide was magnetically stirred at 500 rpm for 12 h at room temperature to prepare a second concentration electrospinning working solution with a PAN concentration of 3.5%. Use tape to fix the stainless steel mesh on the receiving roller of the electrospinning machine, and spin the working solution with PAN concentration of 8% on the stainless steel mesh. The path length was 200 m...

Embodiment 2

[0053] The superhydrophilic nanofiber membrane with gradient structure prepared in Example 1 was used to treat the surfactant-stabilized nanoscale oil-in-water emulsion NE1, and the driving force was 3.0 kPa, and multiple cycles were continuously used for oil-water separation. The oil-water separation effect, anti-pollution and reusability were investigated using the rate, treatment flux and flux recovery rate. The results are attached Figure 4 As shown, the nano-scale oil-in-water emulsion NE1 was treated by this method, the treatment flux was 1143.33LMH, and the flux recovery rate was as high as 99.98%; Percentage of treated flux and first flux (Ji / J 0 ) are higher than 90.9%, and the flux recovery rate is still greater than 86% after 6 reuses, which proves that the superhydrophilic nanofiber membrane with gradient structure prepared by the present invention has high processing flux and ideal oil-water separation effect , The anti-pollution performance is extremely strong...

Embodiment 3

[0055] The nanoscale oil-in-water emulsions NE1 and NE2 stabilized by anionic or cationic surfactants were treated with the superhydrophilic nanofiber membrane with gradient structure prepared in Example 1, and the driving force was 3.0 kPa. The light transmittance and treatment flux were used to investigate the oil-water separation effect. The results are attached Figure 5As shown, the use of this method to treat the nanoscale oil-in-water emulsion stabilized by anionic / cationic surfactants can achieve a very ideal oil-water separation effect, and the oil retention of the nanoscale emulsion NE1 stabilized by anionic surfactant (SLS) can be treated The oil retention rate and light transmittance are 95.68% and 94.3%, respectively, and the treatment flux is 1143.33 LMH / bar, while the treatment of cationic surfactant (CTAB)-stabilized nano-emulsion NE2 is inferior, and the oil rejection and light transmittance are 92.51% and 92.4%, the processing flux is 935.45LMH / bar. It can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com